A production process of 7-series aluminum alloy thick plate with high damage tolerance and low quenching sensitivity

A technology of quenching sensitivity and damage tolerance, applied in the field of aluminum alloy materials, can solve the problems of affecting the fracture toughness, fatigue performance and corrosion resistance of the sheet, restricting the application of Al-Zn-Mg-Cu alloy, and uneven distribution of coarse compounds. , to inhibit the recrystallization process, reduce adverse effects, and improve the effect of solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

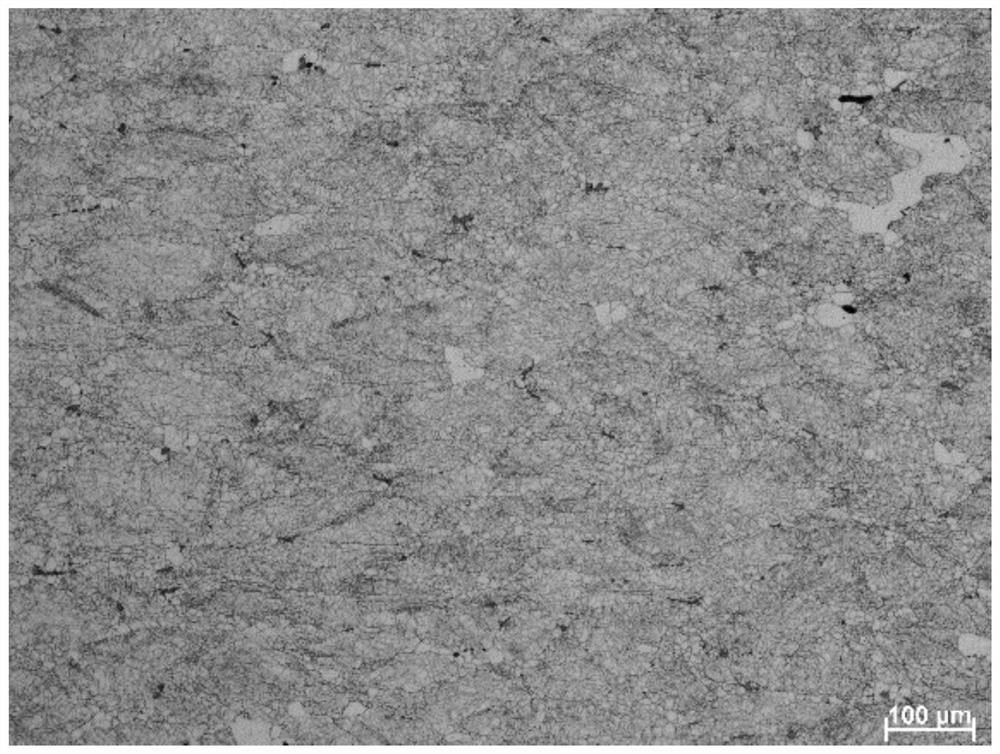

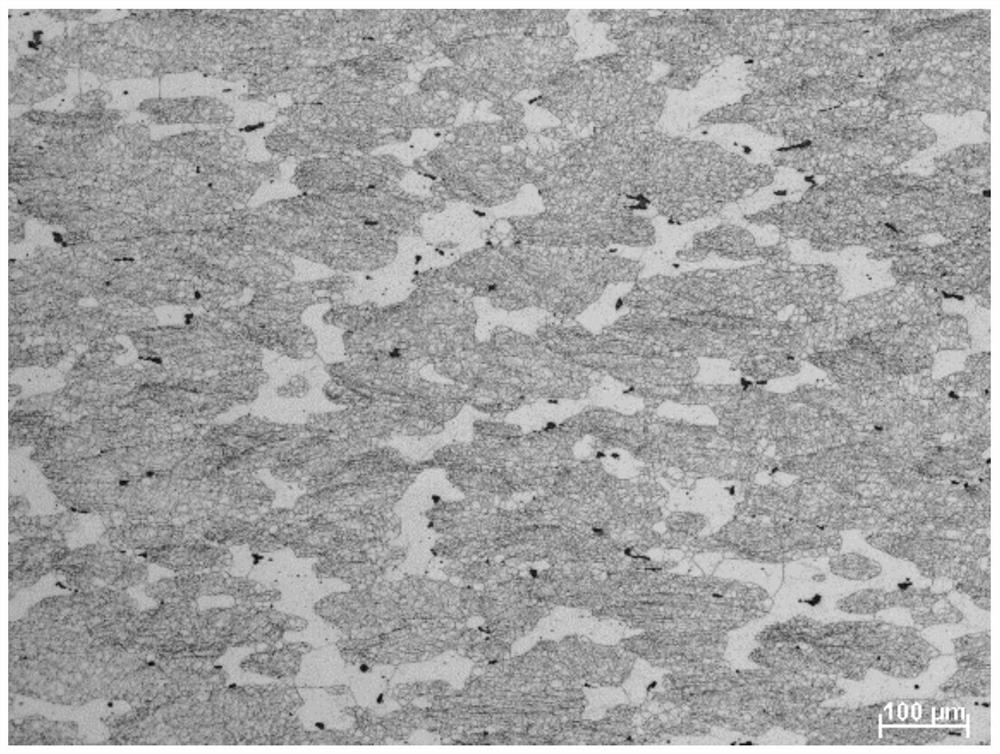

Image

Examples

Embodiment 1

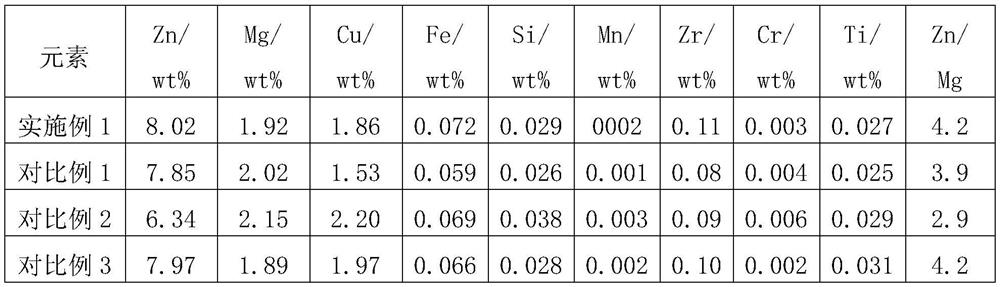

[0061] A production process of Al-Zn-Mg-Cu alloy thick plate with high damage tolerance and low quenching sensitivity for aviation, including ingredients: the alloy formula is composed of the following element components according to weight percentage: Si: 0.029%, Fe: 0.072%, Cu: 1.86%, Mn: 0.002%, Mg: 1.92%, Cr: 0.003%, Zn: 8.02%, Ti: 0.027%, Zr: 0.11%, the balance is aluminum, and the Zn / Mg mass ratio is 4.2.

[0062] The ingredients of the above alloy elements are put into a smelting furnace for smelting, and after slag removal and filtration, the molten aluminum is semi-continuously cast through a crystallizer to form an aluminum alloy hot-rolled slab billet. Put the aluminum alloy slab in a homogenization furnace for homogenization treatment. The ingot is raised from room temperature to 400°C. After holding for 4 hours, it is heated to 462°C at a heating rate of less than 5°C / h. After holding for 16 hours, it is rapidly cooled in the cooling room. cool down.

[0063] The...

Embodiment 1 and comparative example 1

[0081] Table 2 Example 1 and Comparative Examples 1 to 3 Tensile and Fracture Toughness

[0082]

[0083] In Table 2: the superscript ① data is

[0084] From the test results, Example 1 has the highest tensile strength and yield strength, and the strength difference between the core and the surface layer is the smallest. Due to the higher Zn element, Zr element content and Zn / Mg mass ratio, the alloy strength The lifting effect is obvious, and the difference between the core and the surface layer of the material is significantly reduced, and the fracture toughness is relatively low, but the gap is not large. In Comparative Example 1, the Zn content and Zn / Mg mass ratio are slightly lower, but the strength drops significantly, indicating that the Zn content and Zn / Mg mass ratio have a greater impact on the strength of the alloy. The content of Zn element and Zr element in the alloy of Comparative Example 2 is the lowest and the Zn / Mg mass ratio is the smallest, resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com