Process fault identification method based on big data intelligent kernel independent component analysis

A nuclear independent element analysis and fault identification technology, applied in data processing applications, character and pattern recognition, instruments, etc., can solve the problems of abnormal electrode lifting position, leakage furnace failure, spray furnace failure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

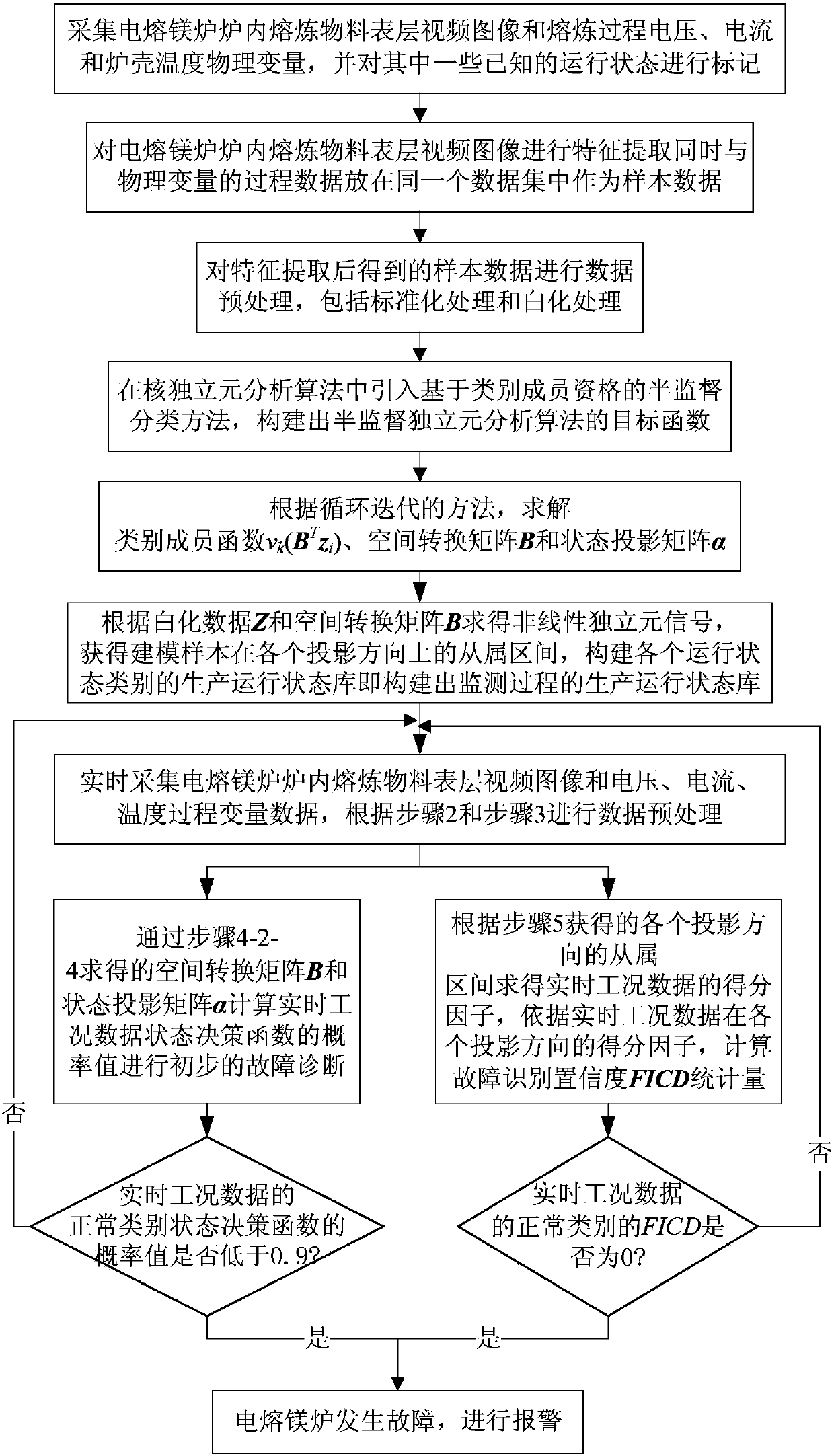

[0068] Such as figure 1 As shown, the process fault identification method based on big data intelligent core independent meta-analysis provided by this embodiment is as follows.

[0069] Step 1: Collect video images of the surface layer of smelting materials in the fused magnesium furnace and physical variables of the smelting process. The physical variables include voltage, current and furnace shell temperature, and mark the obvious and known operating states;

[0070] In this embodiment, the initial tag data X 0l , and its corresponding label is At the same time, the initial unlabeled data set is X 0u , X 0 =[X 0l , X 0u ], sample number n=n l +n u , n l and n ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com