Baking method of seven-bud daylilies

A roasting method and technology of yellow flowers, which are used in food drying, food science and other directions, can solve the problems of limited smoke, bitter yellow flowers, and insufficient combustion of wood, and achieve the effect of accelerating airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

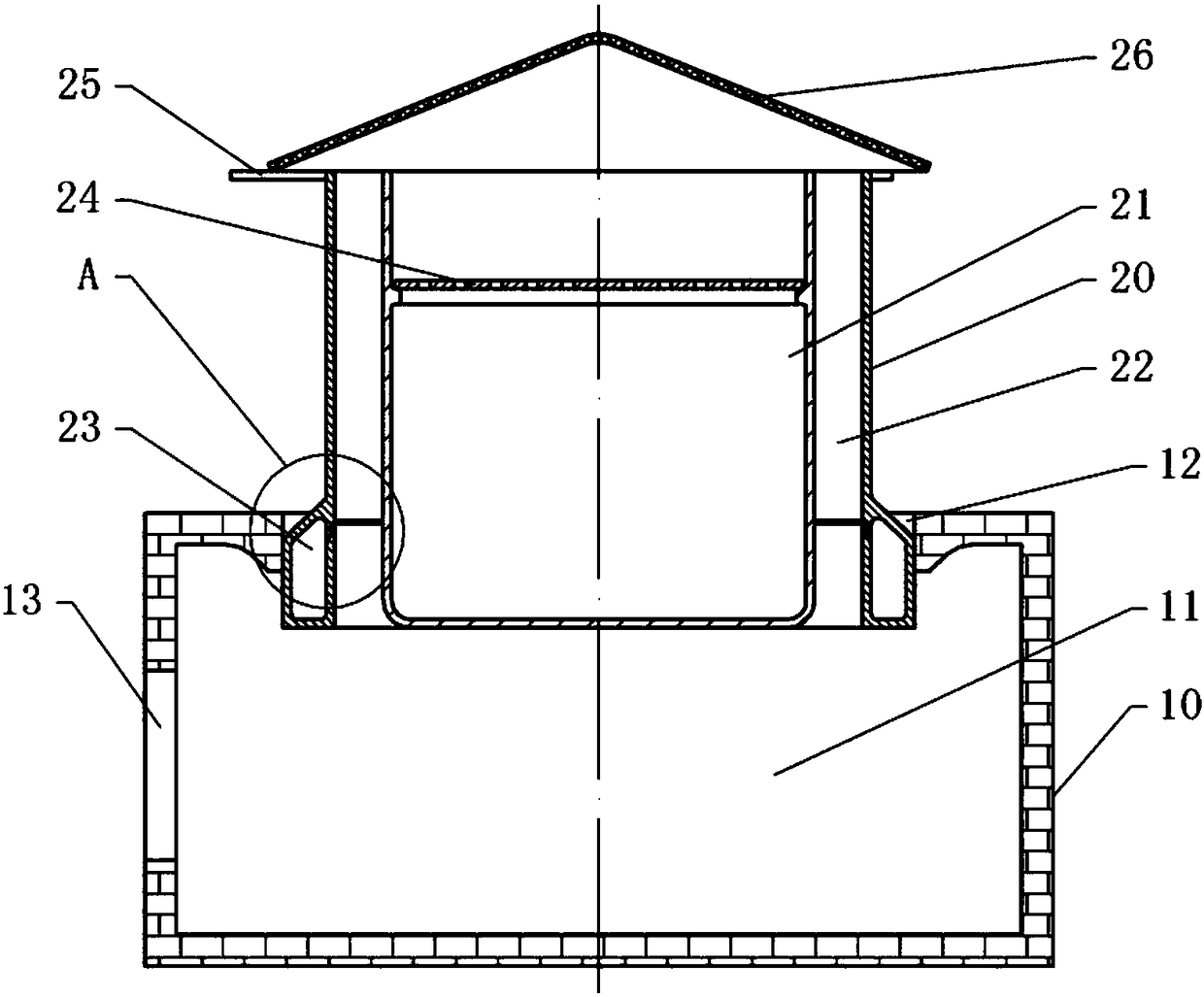

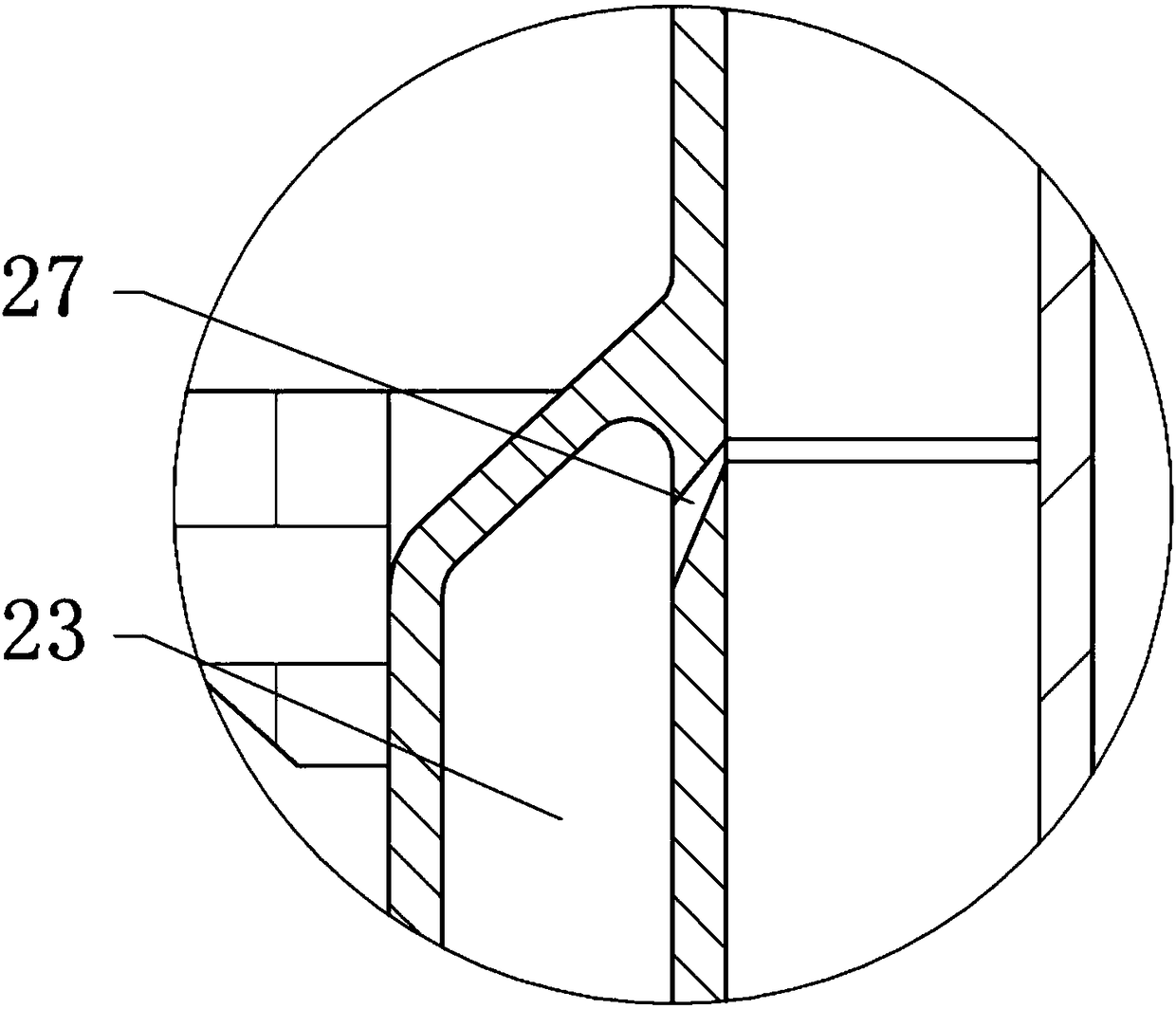

[0028] The reference signs in the drawings of the description include: combustion part 10, combustion chamber 11, heat exhaust port 12, feeding port 13, steaming part 20, steaming cylinder 21, smoke exhaust channel 22, water cavity 23, steaming plate 24, support Rod 25, cover body 26, annular wedge 27.

[0029] The yellow flower steaming device used for steaming the seven-stamen yellow flower is as follows: figure 1 , figure 2 As shown, the yellow flower steaming device includes a combustion part 10 and a steaming part 20 , and the steaming part 20 is arranged above the combustion part 10 . The combustion part 10 comprises a combustion chamber 11, a feeding port 13 located on the side of the combustion chamber 11, and a heat exhaust port 12 located at the top of the combustion chamber 11. The feeding port 13 is used to put wood to be burned in the combustion chamber 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com