Control method for improving water balance dynamic characteristics of string tower desulfurization system

A desulfurization system and control method technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as the rapid drop in the liquid level of the first-stage tower, and the difficult water balance in the desulfurization system of the series tower, so as to improve the dynamic The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

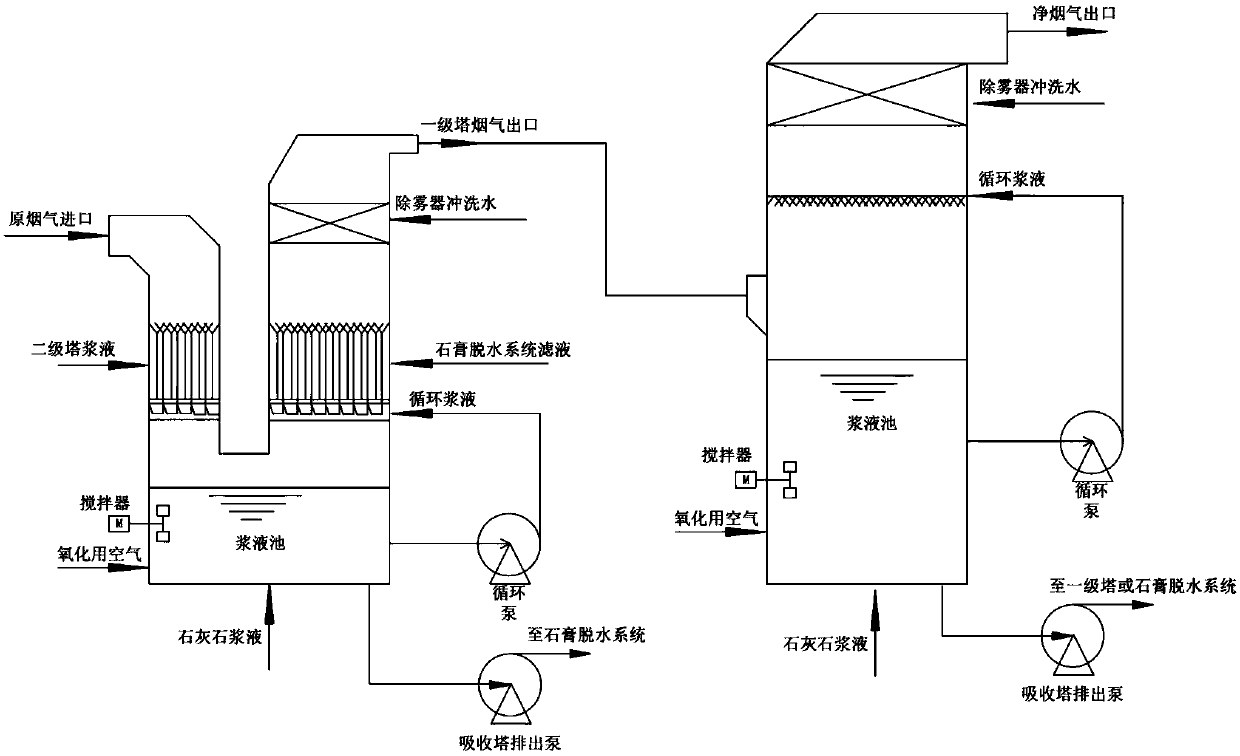

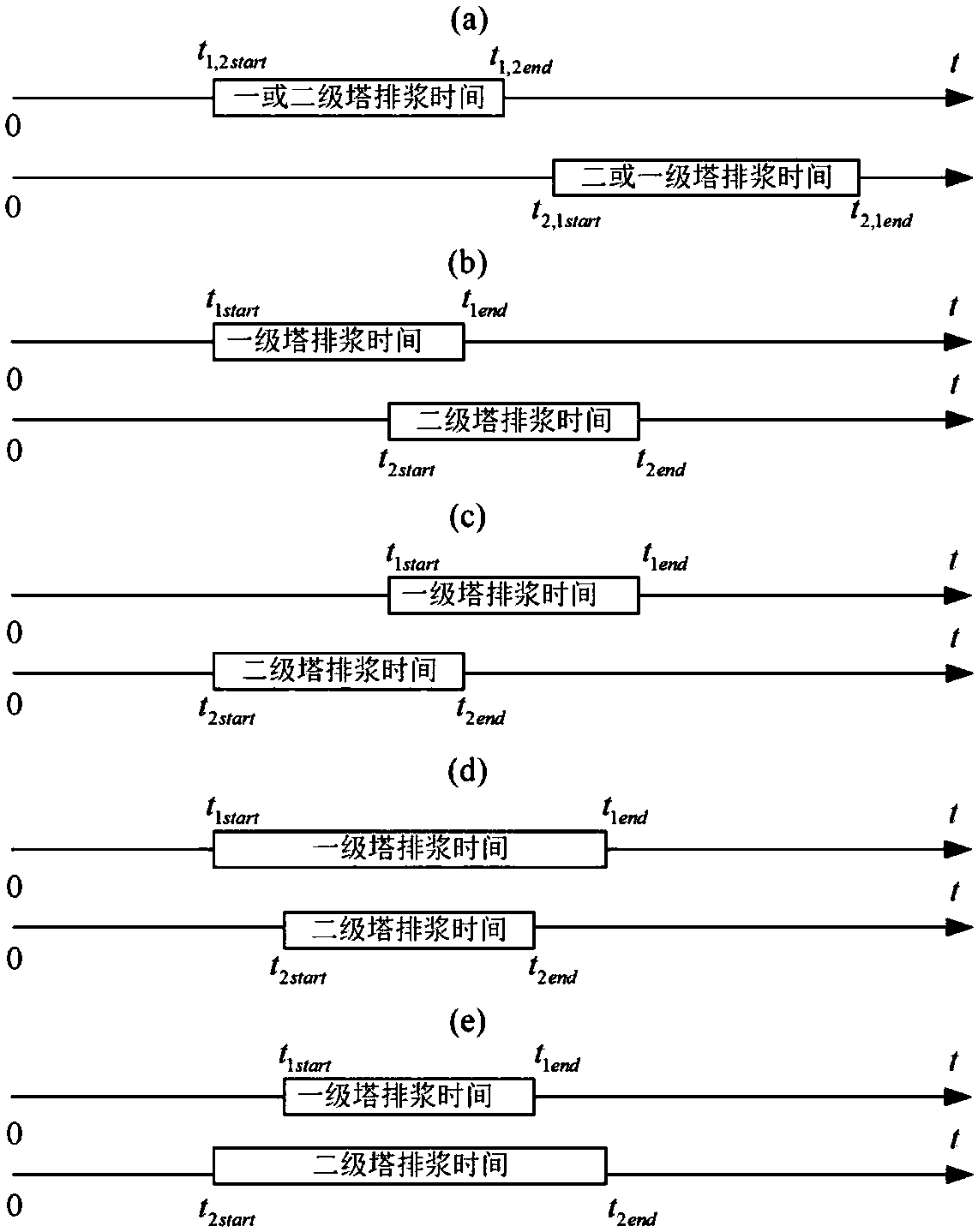

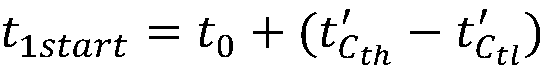

[0040] The process flow of the string tower desulfurization system is as follows: figure 1 As shown, the raw flue gas first passes through the primary tower to remove most of the SO 2 , the net flue gas carries a large amount of water into the secondary tower for desulfurization again; during normal operation, the slurry in the secondary tower is discharged from the pump to replenish water in the primary tower; when the gypsum concentration of the slurry in the primary and secondary towers reaches the discharge pump start threshold The gypsum discharge pump runs to discharge the gypsum slurry to the gypsum dehydration system, and the filtrate is returned to the first-stage tower. In actual operation, the time periods for discharging gypsum slurry from the primary and secondary towers may be completely staggered, partially overlapped or com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com