Remote crusher data collection system

A technology for collecting system and remote data, applied in the direction of grain processing, etc., can solve the problems of inability to reduce energy consumption production efficiency, inability to realize real-time monitoring of crushers, and inability to use crusher data collection, etc., to facilitate adjustment and reduce energy consumption. , the effect of reasonable safety supervision and protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

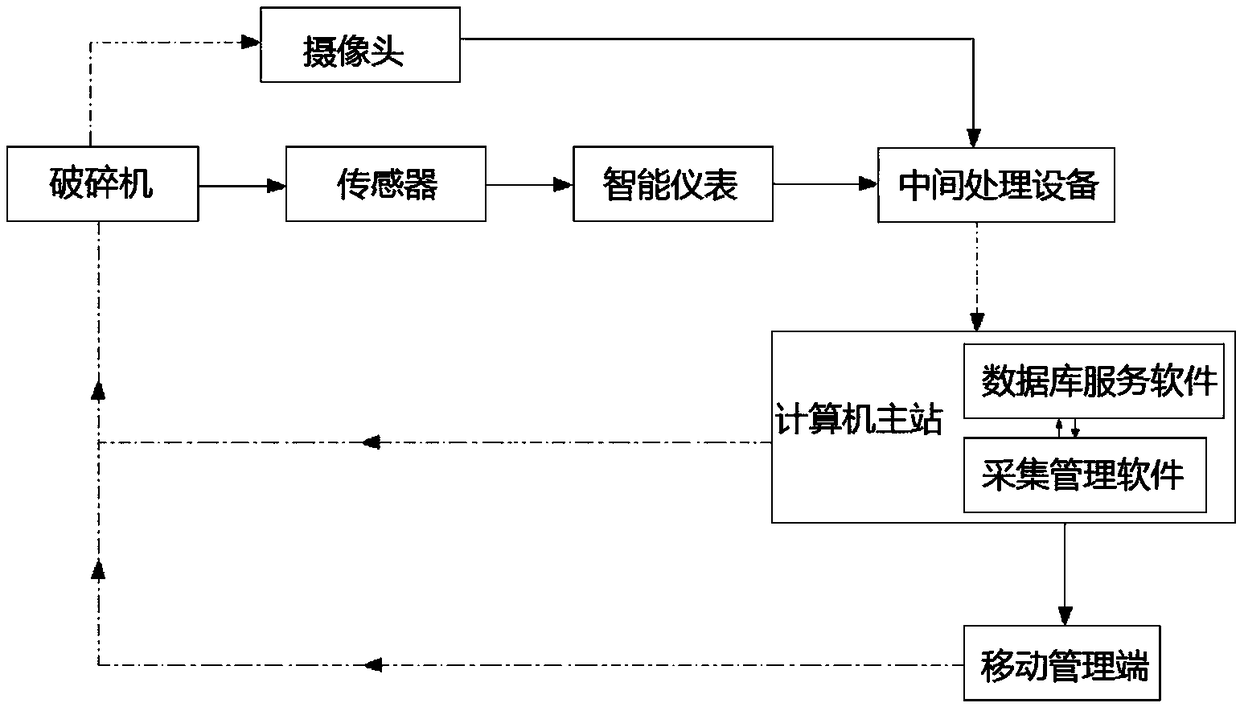

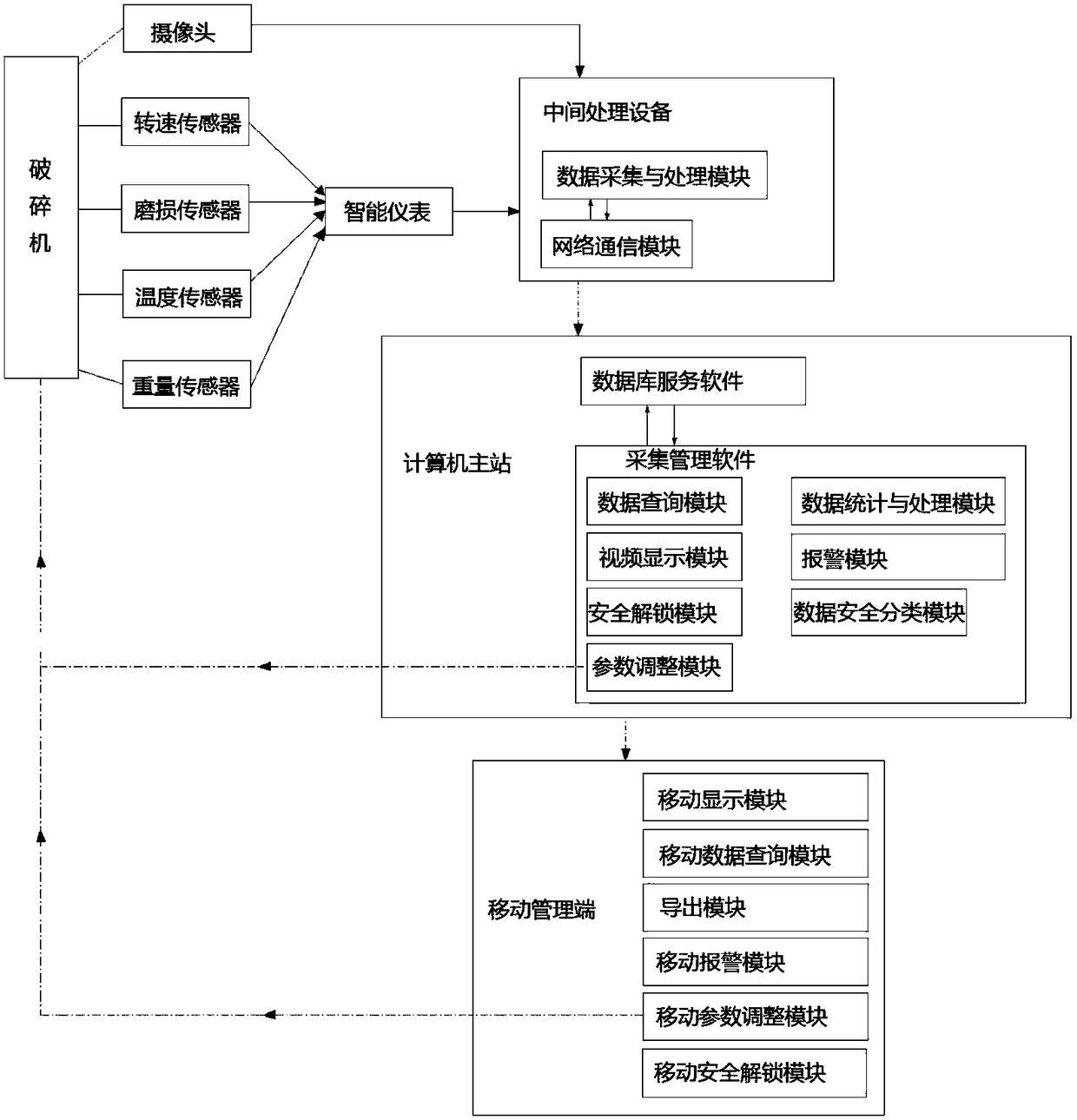

[0031] In this example, if Figure 1-3 As shown, a crusher remote data acquisition system, the system includes a computer master station, acquisition management software, database server software, intermediate processing equipment, smart meters, sensors, cameras and mobile management terminals;

[0032] The computer master station is provided with acquisition management software and database server software for storing all data, and the acquisition management software includes a video display module, a data statistics and processing module, a data security classification module, a data query module, an alarm module, A parameter adjustment module for adjusting the working parameters of the crusher and a security unlocking module for unlocking the acquisition management sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com