Resin and corundum composite grinding wheel provided with brazed diamond insert pieces and manufacturing process thereof

A manufacturing process and diamond technology, which is applied in the field of brazed diamond-inserted resin-corundum composite grinding wheel and its manufacturing process, can solve the problems of easy burns on the grinding surface, low grinding capacity of rigid grinding wheels, and low grinding efficiency. The effect of improving the quality of the polished surface, increasing the working life and reducing the working intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention discloses a preparation process of a grinding insert grinding wheel with an outer diameter of 150 mm. Specific steps are as follows:

[0037] Step 1: Make brazed diamond inserts: According to the actual effective working thickness of the 150mm-diameter rail grinding wheel, use 303 stainless steel with a thickness of 0.2mm to cut and make an insert base with a length of 55mm and a width of 20mm. 40 / 45 mesh diamonds are used as brazing abrasive grains, which are randomly arranged on both sides of the insert substrate, and the density of abrasive grains on one side is 60%. Using nickel-based brazing diamond filler metal, the diamond abrasive is brazed and consolidated through a vacuum brazing furnace;

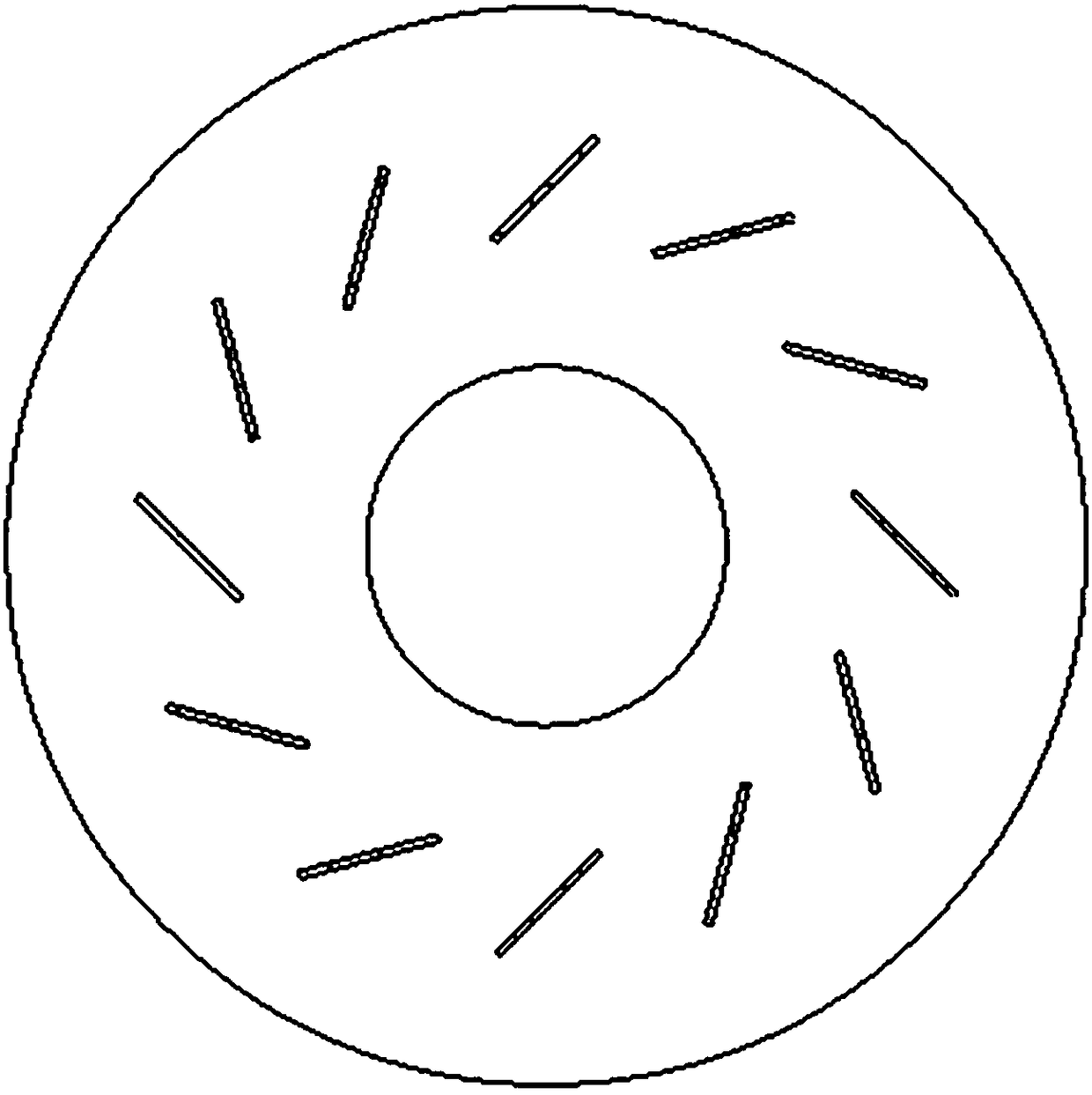

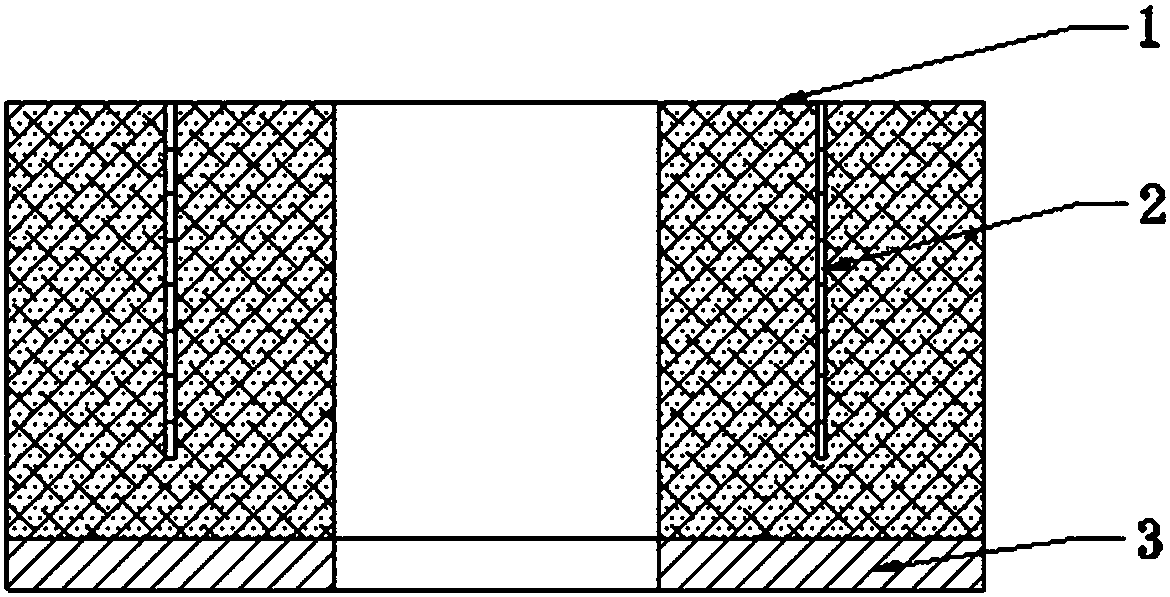

[0038] Step 2: Insert the corresponding number of inserts: In order to make the diamond abrasive grains on the inserts and the corundum abrasives in the resin alternately grind, the value of k in the calculation formula is 0.5. The design insert placement an...

Embodiment 2

[0043] A preparation process of a composite grinding wheel for rail grinding with an outer diameter of 250mm. Specific steps are as follows:

[0044] Step 1: Making brazed diamond inserts: According to the actual effective working thickness of the 250mm-diameter rail grinding wheel, use 303 stainless steel with a thickness of 0.3mm to cut and make an insert base with a length of 30mm and a width of 22mm. 35 / 40 mesh diamond is selected as brazing abrasive grains, which are arranged randomly on both sides of the insert substrate, and the density of abrasive grains on one side is 65%. Using nickel-based brazing diamond filler metal, the diamond abrasive is brazed and consolidated in a vacuum brazing furnace.

[0045] Step 2: Insert the corresponding number of inserts: design and place the upper and lower layers of brazed diamond inserts in the grinding wheel. The diamond abrasive grains on the inserts and the corundum abrasives in the resin are alternately ground. The k value in t...

Embodiment 3

[0050] A preparation process of a composite grinding wheel for rail grinding with an outer diameter of 260mm. Specific steps are as follows:

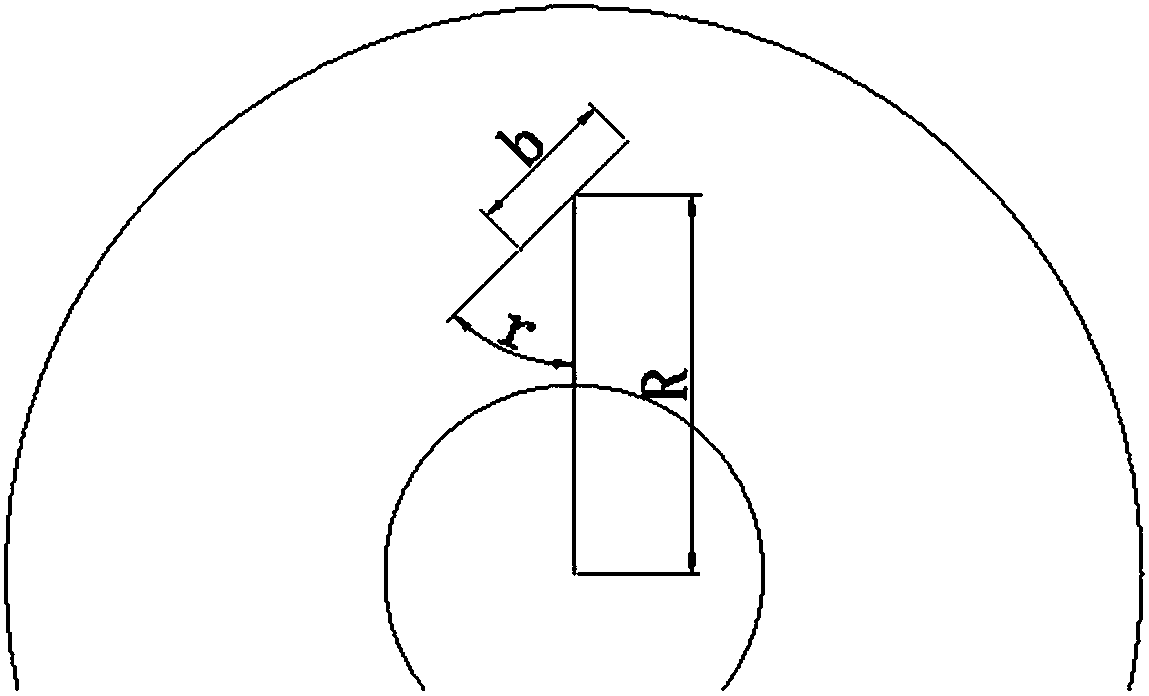

[0051] Step 1: Make brazed diamond inserts. According to the actual effective working thickness of the 260mm-diameter rail grinding wheel, use 303 stainless steel with a thickness of 0.3mm to cut and manufacture the insert substrate with a length of 60mm and a width of 24mm. 30 / 35 mesh diamond is selected as the brazing abrasive grain, on both sides of the insert substrate such as image 3 Arranged in an orderly manner as shown, the density of abrasive grains on one side is 70%. Using nickel-based brazing diamond filler metal, the diamond abrasive is brazed and consolidated in a vacuum brazing furnace.

[0052] Step 2: In order to make the inserts can continuously participate in the grinding work during grinding, take the value of k in the calculation formula as 1. The design insert placement angle r is 60°, the central circle radiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com