Alkaline thermal hydrolysis treatment method and system for sludge

A treatment system and treatment method technology, applied in the field of sludge alkaline thermal hydrolysis treatment method and system, to achieve the effect of maximizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

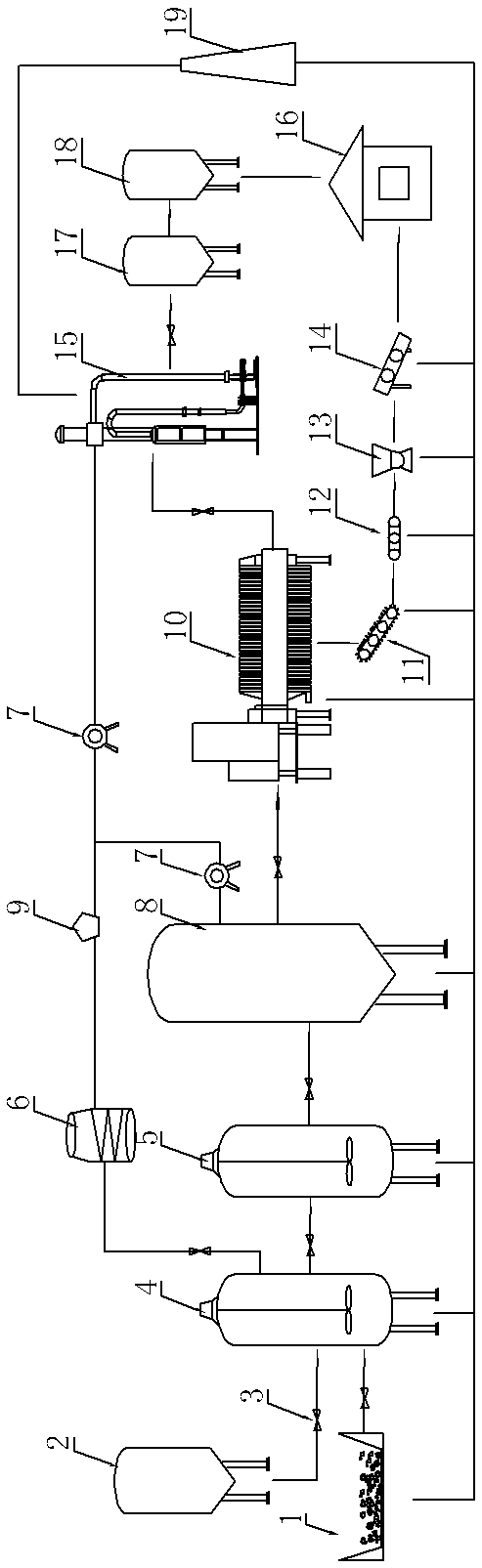

Method used

Image

Examples

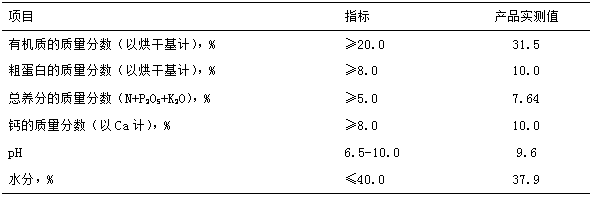

Embodiment 1

[0025] A sludge alkaline thermal hydrolysis treatment method is characterized in that it comprises the following steps:

[0026] (1) Sludge blending and preheating, put the sludge (collected from Shanxi Sewage Treatment Co., Ltd.) and hydrolysis agent into the sludge blending and preheating device, adjust the sludge to a moisture content of 86%, and a temperature of 70°C, then hydrolyze The agent is quicklime, and the proportion of quicklime added is 20% of the dry weight of the sludge;

[0027] (2) Sludge hydrolysis reaction, the prepared and preheated sludge is transported to the hydrolysis reaction device, heated to 123°C, and stayed for 3 hours to complete the hydrolysis reaction process;

[0028] (3) Sludge flash evaporation, the sludge that has completed the hydrolysis reaction is transported to the flash tank for flash evaporation for 0.5 hours;

[0029] (3) Sludge solid-liquid separation. After the sludge hydrolysis reaction, the solid-liquid separation is carried out...

Embodiment 2

[0037] The difference between the method of Example 2 and the method of Example 1 is that the addition ratio of quicklime is 22.5% of the dry weight of the sludge, the deployment preheating temperature is 90°C, the thermal hydrolysis reaction temperature is 120°C, and a constant temperature of 120°C is maintained for 2 Hour.

[0038] The nutritional components and properties of the residue obtained in step (3) were analyzed. The water content was 38.2%, the pH value was 9.8, the calcium content was 11.3%, the organic matter content was 32.5%, the crude protein content was 10.3%, and the overall nutrient content was 7.73%, which met the requirements of the standard.

[0039] The filtrate obtained in step (3) was subjected to a pot test, in which the green vegetables in group A averaged 236.5g each, which was 71% higher than the 138.3g growth rate in group B, and the cherry radishes in group C averaged 16.8g each. Compared with the 10.3g growth rate of group D, the growth rate h...

Embodiment 3

[0041] The difference between the method of Example 3 and the method of Example 1 is that the addition ratio of quicklime is 18% of the dry weight of the sludge, the deployment preheating temperature is 80°C, the thermal hydrolysis reaction temperature is 125°C, and the constant temperature of 125°C is kept at 2.5°C. Hour.

[0042] The nutritional components and properties of the residue obtained in step (3) were analyzed. The water content was 39.0%, the pH value was 8.6, the calcium content was 9.4%, the organic matter content was 30.9%, the crude protein content was 9.8%, and the overall nutrient content was 7.52%, which met the requirements of the standard.

[0043] The filtrate obtained in step (3) was subjected to a pot test, in which the green vegetables in group A averaged 211.6g each, which was 72% higher than the 123g growth rate in group B, and the cherry radishes in group C averaged 16.5g each. Compared with the 11g growth rate of group D, it increased by 59.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com