Cleaning treatment technology for isopropyl chloride cyanuric acid production waste water

The technology of chlorinated isocyanuric acid and sodium dichloroisocyanurate is applied in the field of cleaning treatment technology of chlorinated isocyanuric acid production wastewater, which can solve the problems of comprehensive utilization of environmental resources polluted by production wastewater, and achieve comprehensive utilization of resources, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

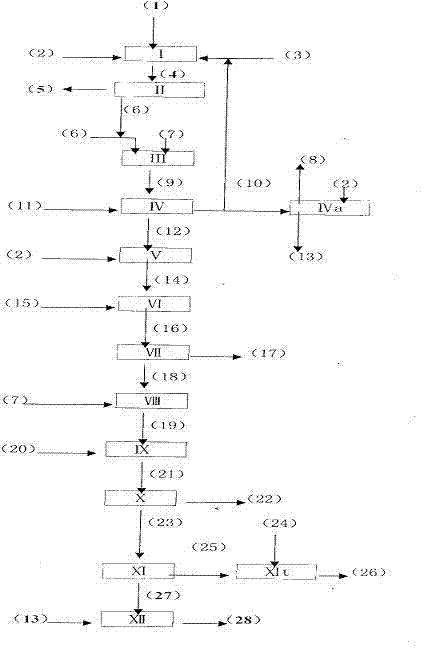

[0069] Step A: Send the mother liquor (1) produced by the production of sodium dichloroisocyanurate into the 7000L chlorination reactor (I) at a rate of 5800kg / h through a flowmeter, and simultaneously, according to the content of cyanuric acid and available chlorine in the mother liquor Send the liquid caustic soda (2) of the calculated amount (calculated according to the following formula) into the chlorination reactor (I), turn on the mixer of the chlorination reactor (I), and make the mother liquor (1) and the liquid caustic soda (2) in the chlorination reactor (I) Mix well in the reactor (I), and at the same time, feed frozen brine into the jacket of the reactor (I), and feed chlorine gas (3) or chlorine-containing tail gas from the dechlorination tower through the chlorine pipe and distributor under stirring (10) Keep the reaction solution at a pH of 2.8-3.2, and keep the temperature at 15-25°C for chlorination, and keep a constant liquid level in the reactor (that is, th...

Embodiment 2

[0088] Step A: Send the mother liquor (1) produced by the production of sodium dichloroisocyanurate into the 7000L chlorination reactor (I) at a rate of 5800kg / h through a flowmeter, and simultaneously, according to the content of cyanuric acid and available chlorine in the mother liquor Send the liquid caustic soda (2) of the calculated amount (calculated according to the following formula) into the chlorination reactor (I), turn on the mixer of the chlorination reactor (I), and make the mother liquor (1) and the liquid caustic soda (2) in the chlorination reactor (I) Mix well in the reactor (I), and at the same time, feed frozen brine into the jacket of the reactor (I), and feed chlorine gas (3) or chlorine-containing tail gas from the dechlorination tower through the chlorine pipe and distributor under stirring (10) Keep the reaction solution at a pH of 3.0 to 3.4, and keep the temperature at 5 to 15°C for the chlorination reaction to keep a constant liquid level in the reac...

Embodiment 3

[0098] Step A is the same as in Example 1.

[0099] Step B: Blowing off The dechlorination tower (VI) is a packed tower, and a two-tower series gas-liquid countercurrent blowing off process is adopted. The mother liquor (6) produced by the production of chloroisocyanuric acid is about 20600kg / h and 31% hydrochloric acid (7) 100-140kg / h from the hydrochloric acid head tank are pumped into the static mixer (Ⅲ) for acidification and mixed The pH value of the liquid is maintained at 1 to 2, and the mixed acidified mother liquor (9) in the static mixer (Ⅲ) is blown off from the second dechlorination tower (Ⅵ) at normal temperature 2 ) into the upper part, from its tower (Ⅵ 2 ) The lower part comes out and enters the 2nd tower (Ⅵ 2 ) bottom liquid collection tank, and pump its mother liquor into the first blow off dechlorination tower (Ⅵ 1 ) of the upper part, and then by its tower (Ⅵ 1 ) comes out from the lower part and enters Tower 1 (Ⅵ 1 ) Bottom liquid collection tank. Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com