Method for preparing manganese sulfate solution with low manganous dithionate through desulfuration by using slurry prepared by anode liquid and manganese ore

A technology of manganese dithionate and anolyte, which is used in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of small mass transfer driving force and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

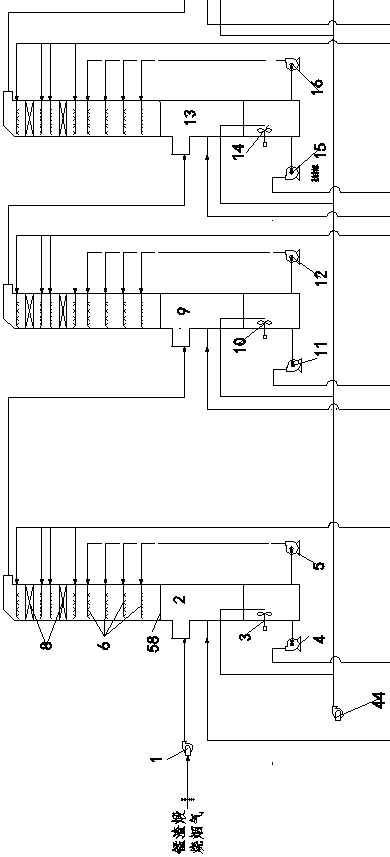

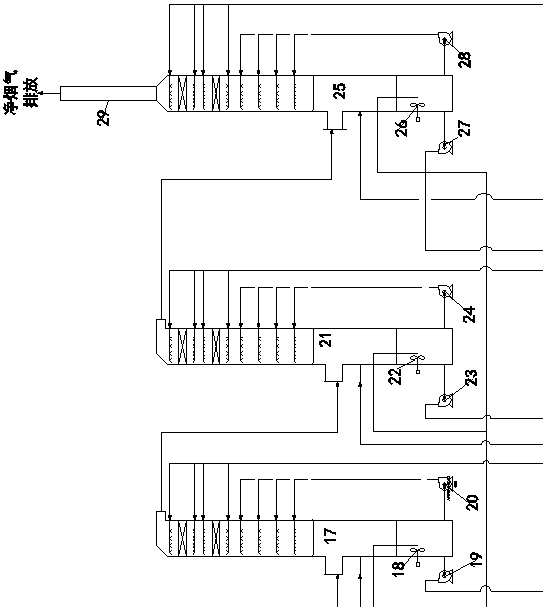

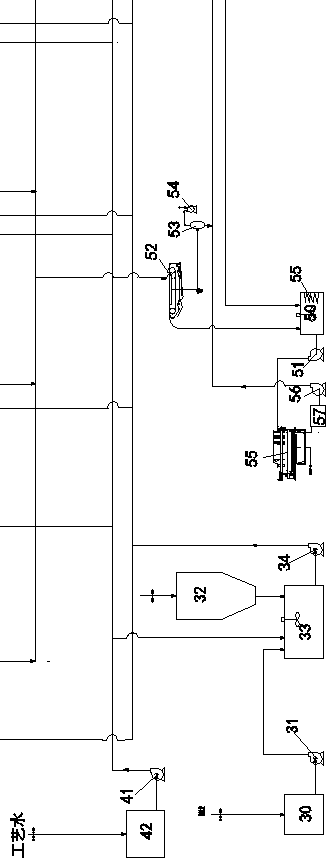

Method used

Image

Examples

Embodiment 1

[0063] The temperature of flue gas to be treated entering the flue gas desulfurization system is 185°C, and the flue gas volume is 199,000m 3 / h, the composition of the flue gas is shown in Table 1 below.

[0064] Table 1 Smoke composition

[0065] components

N 2

CO 2

h 2 o

O 2

SO 2

Content, v%

65.28

16.00

11.18

2.78

4.75

[0066] The composition analysis in the manganese ore powder bin 32 is shown in Table 2 below.

[0067] Table 2 Composition of manganese ore powder

[0068]

[0069]

[0070] The composition of the electrolytic manganese anolyte used for slurry preparation is shown in Table 3 below.

[0071] Table 3 is used to configure the anolyte of manganese ore slurry

[0072] components

All Mn

Divalent Mn

H +

pH

Content g / l

14.19

13.41

14.74

0.35

[0073] The specific operation is as follows.

[0074] 1. The anolyte in the anolyte storage tank 30 is...

Embodiment 2

[0083] The temperature of the flue gas to be treated entering the flue gas desulfurization system is 200°C, and the flue gas volume is 158,000m 3 / h, the composition of the flue gas is shown in Table 4 below.

[0084] Table 4 Smoke composition

[0085] components

N 2

CO 2

h 2 o

O 2

SO 2

Content, v%

67.5

14.9

10.6

3.2

3.8

[0086] The composition analysis in the manganese ore powder bin 32 is shown in Table 5 below.

[0087] Table 5 Composition of manganese ore powder

[0088] components

All Mn

Tetravalent Mn

Divalent Mn

Content, wt%

37.48

16.90

4.52

[0089] The composition of the electrolytic manganese anolyte used for slurry preparation is shown in Table 6 below.

[0090] Table 6 is used to configure the anolyte of manganese ore slurry

[0091] components

All Mn

Divalent Mn

H +

pH

Content g / l

14.19

13.41

14.74

0.35

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com