al-mg alloy and its preparation method

An alloy and aluminum alloy technology, which is applied in the field of Al-Mg alloy and its preparation, can solve the problems that the special-shaped extruded material cannot be subjected to cold work hardening treatment, it is difficult to meet the strength requirements, and the strength is low. Weld hot crack tendency, enhancement and effect of weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The Al-Mg alloy described in this embodiment, by mass percentage, includes the following components:

[0033] Si 0.44%, Mg 2.1%, Mn 0.05%, Cr 0.15%, Cu 0.04%, and the balance is Al; among them, the control impurities include Fe≤0.12%, Ti≤0.10%, Zn≤0.05, and the total amount of other impurities < 0.15%.

[0034] The raw materials for preparing the above-mentioned aluminum alloy extruded rods are as follows:

[0035] Aluminum ingots: Aluminum ingots with the brand name Al99.7 are used, and the mass percentage of Al in the aluminum ingots is more than 99.70%, which meets the standard GB / T 1196-2008 "Aluminum Ingots for Remelting";

[0036] Magnesium ingots: Magnesium ingots with the brand Mg9990 are used, and the mass percentage of Mg in the magnesium ingots is more than 99.9%, which meets the standard GB / T 3499-2003 "Primary Magnesium Ingots";

[0037] Aluminum-silicon alloy: crystalline silicon and aluminum-silicon alloy are used, and the mass percentage of aluminum-si...

Embodiment 2

[0059] The Al-Mg alloy described in this embodiment includes the following components in terms of mass percentage: 0.53% Si, 2.4% Mg, 0.05% Mn, 0.15% Cr, 0.14% Cu, and the balance is Al; Among the impurities, Fe≤0.12%, Ti≤0.10%, Zn≤0.05, and the total amount of other impurities <0.15%.

[0060] The raw materials used in this embodiment and the specific process steps are the same as in Example 1.

Embodiment 3

[0062] The composition of the Al-Mg alloy described in this embodiment also includes 0.0001%-0.005% of Be, and the rest of the components are the same as in Example 2, and the raw materials and specific process steps used are also the same as in Example 2.

PUM

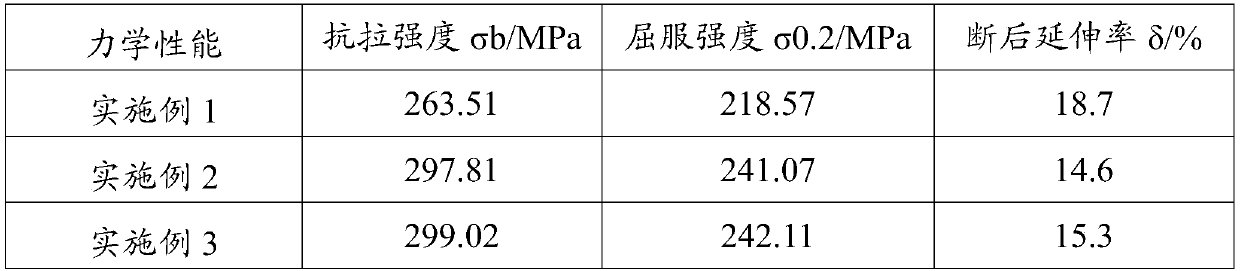

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com