Intelligent module

A technology of intelligent modules and wires, applied in the directions of registration/indication of machine work, registration/instruction, time register, etc., can solve the problem of increasing the work intensity of maintenance personnel, the inability to monitor the working time of elevators, and the inability to ensure the reliable use of elevators. problems such as stability, to achieve the effect of easy installation, reduced size, and avoidance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

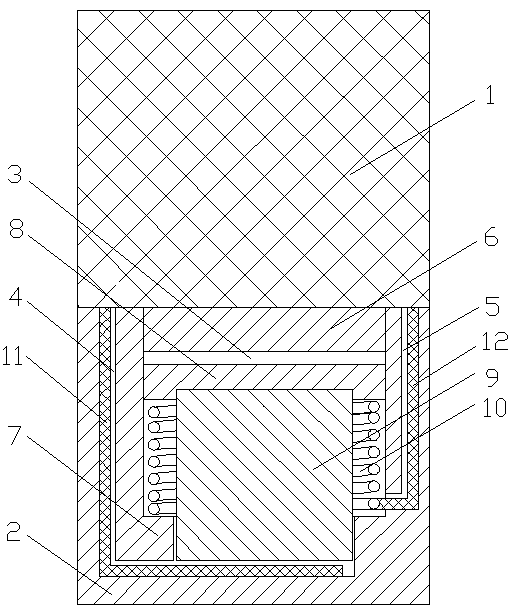

[0033] An intelligent module includes a chip 1 and a bracket 2, the chip 1 is fixed on the bracket 2, and the inside of the bracket 2 is provided with a mounting hole 3, a first wire channel 4 and a second wire channel 5, and the mounting hole 3 is provided with a plug 6 for closing the installation hole 3, and a step 7 is provided below the installation hole 3, and a limiter 8 and a magnet 9 are installed in the installation hole 3; the limiter 8 is a ferromagnetic metal, and the limiter The plate 8 is provided with a counterbore matching the diameter of the magnet 9, and the magnet 9 is inserted into the counterbore and absorbed into the limit piece 8 as a whole; the magnet 9 is cylindrical, and the outside of the magnet 9 is covered with a spring 10. One end of the spring 10 is in contact with the step 7, and the other end is in contact with the stopper 8; the first wire channel 4 is provided with a first wire 11, and the second wire channel 5 is provided with a second wire 12...

Embodiment 2

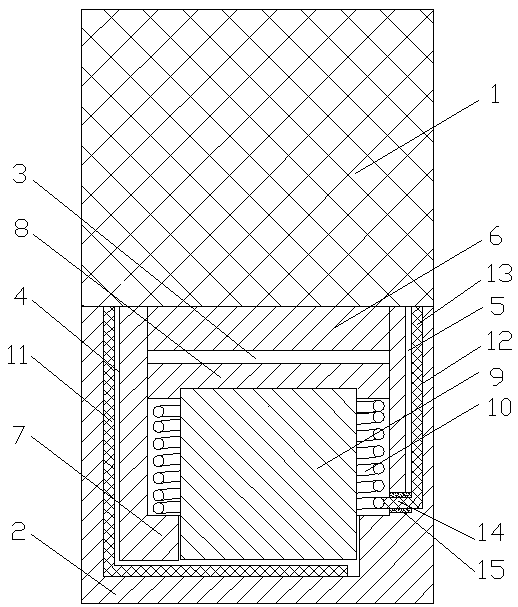

[0036] An intelligent module includes a chip 1 and a bracket 2, the chip 1 is fixed on the bracket 2, and the inside of the bracket 2 is provided with a mounting hole 3, a first wire channel 4 and a second wire channel 5, and the mounting hole 3 is provided with a plug 6 for closing the installation hole 3, and a step 7 is provided below the installation hole 3, and a limiter 8 and a magnet 9 are installed in the installation hole 3; the limiter 8 is a ferromagnetic metal, and the limiter The plate 8 is provided with a counterbore matching the diameter of the magnet 9, and the magnet 9 is inserted into the counterbore and absorbed into the limit piece 8 as a whole; the magnet 9 is cylindrical, and the outside of the magnet 9 is covered with a spring 10. One end of the spring 10 is in contact with the step 7, and the other end is in contact with the stopper 8; the first wire channel 4 is provided with a first wire 11, and the second wire channel 5 is provided with a second wire ...

Embodiment 3

[0044] An intelligent module includes a chip 1 and a bracket 2, the chip 1 is fixed on the bracket 2, and the inside of the bracket 2 is provided with a mounting hole 3, a first wire channel 4 and a second wire channel 5, and the mounting hole 3 is provided with a plug 6 for closing the installation hole 3, and a step 7 is provided below the installation hole 3, and a limiter 8 and a magnet 9 are installed in the installation hole 3; the limiter 8 is a ferromagnetic metal, and the limiter The plate 8 is provided with a counterbore matching the diameter of the magnet 9, and the magnet 9 is inserted into the counterbore and absorbed into the limit piece 8 as a whole; the magnet 9 is cylindrical, and the outside of the magnet 9 is covered with a spring 10. One end of the spring 10 is in contact with the step 7, and the other end is in contact with the stopper 8; the first wire channel 4 is provided with a first wire 11, and the second wire channel 5 is provided with a second wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com