Submersible well type multi-cylinder vertical plunger oil well pump

The technology of oil well pump and plunger is applied in the field of submerged well type multi-cylinder vertical plunger oil well pump, which can solve the problems of high use cost, easy loss of sucker rod and high cost, achieve simple disassembly process and improve oil pumping efficiency , the effect of low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

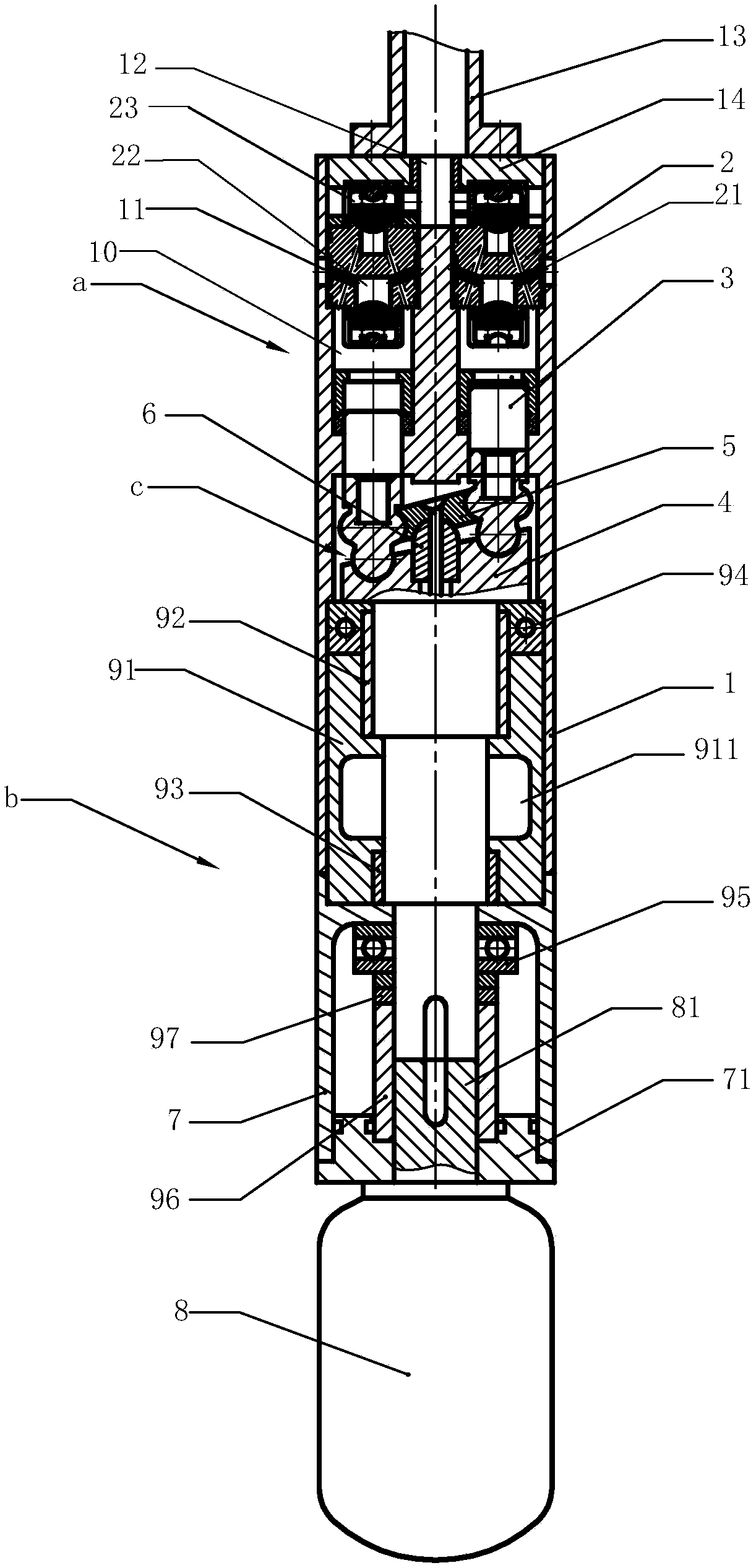

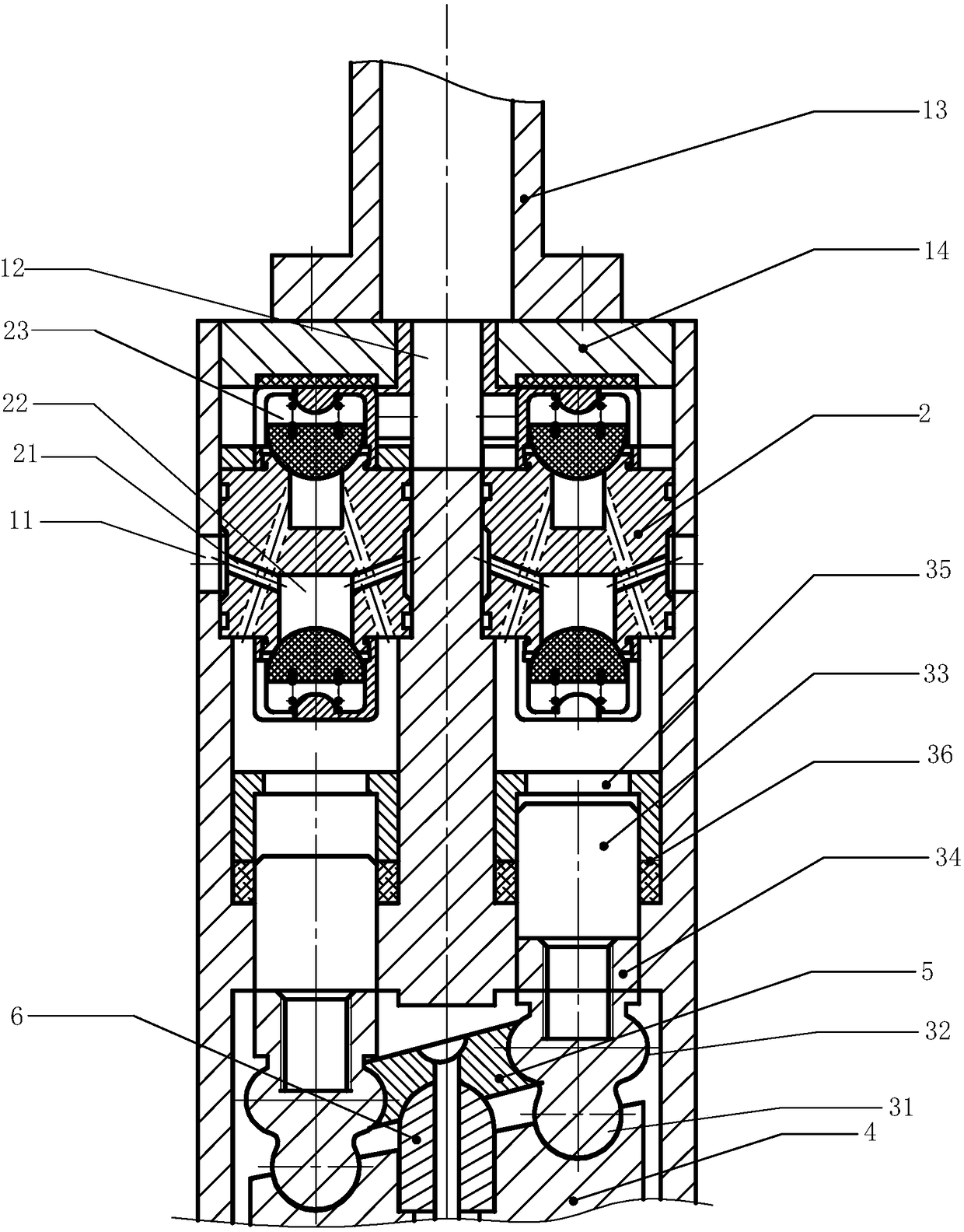

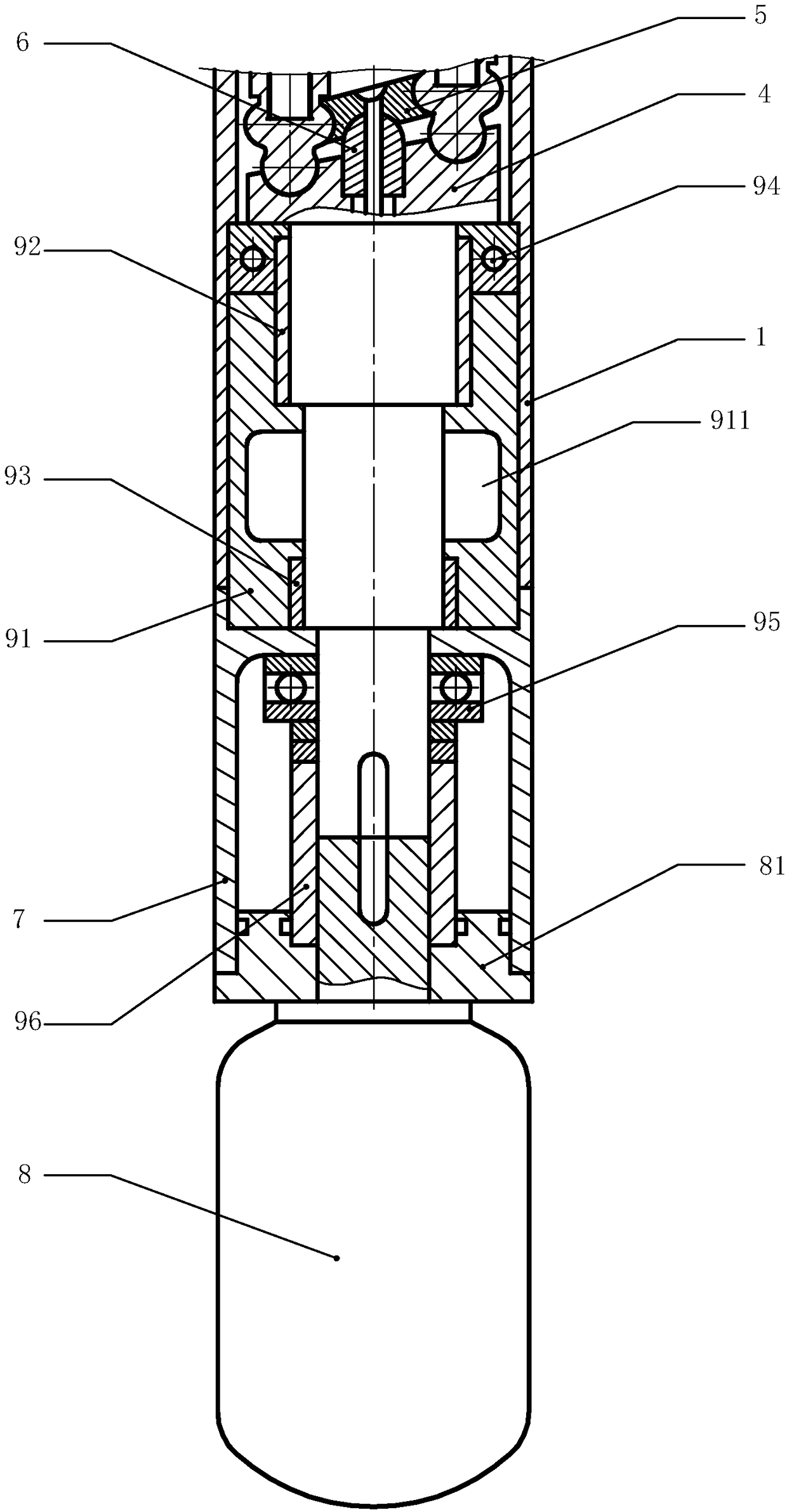

[0039] Such as Figure 1-11 As shown, the submersible multi-cylinder vertical plunger oil well pump of this embodiment includes a pump body 1 and a hydraulic end a and a power end b arranged in the pump body 1, the pump body 1 is cylindrical, and the power end b is used for It operates by driving liquid end a. The pump body 1 integrates the fluid end a and the power end b, and the fluid end a is arranged on the upper side of the pump body 1 , and the power end b is arranged on the lower side of the pump body 1 .

[0040]In this embodiment, the hydraulic end a includes a combined valve 2 and a plunger 3. The hydraulic end a of this embodiment has a three-cylinder structure, that is, there are three combined valves 2. Of course, the number of combined valves 2 can also be determined according to In actual use, the size of the oil well casing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com