Automobile absorber recovery valve-system structure based on runway-type valve plates

A recovery valve, racetrack-type technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as excessive deformation, poor durability, fracture, etc., to achieve the effect of ensuring stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

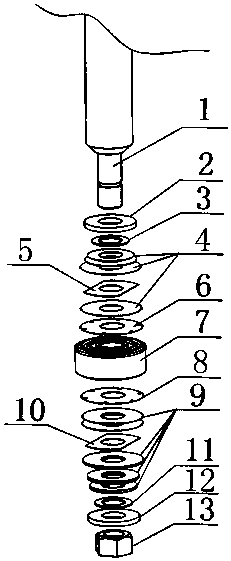

[0027] A car shock absorber recovery valve train structure based on a racetrack valve plate, including a piston rod 1, a piston 7 and a hex nut 13, characterized by:

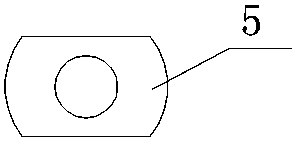

[0028] On the top of the piston 7, from top to bottom, there are a flow valve common gasket 2, a flow valve adjustment gasket 3, four flow valve adjustable valve plates 4, and a flow valve raceway valve plate, which are sleeved on the piston rod 1. 5 and a flow valve multi-slot valve piece 6, the flow valve runway type valve piece 5 is arranged between the four flow valve adjustable valve pieces 4;

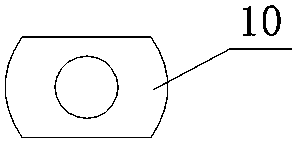

[0029] Between the bottom of the piston 7 and the hexagonal nut 13, there are a reset valve multi-slot valve plate 8 set on the piston rod 1, eight reset valve adjustable valve plates 9, and a reset valve raceway valve from top to bottom. Sheet 10, a recovery valve adjustment gaske...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap