Magnetorheological fluid characteristic tester

A magnetorheological fluid and tester technology, which is used in the measurement of magnetic properties, measuring magnetic variables, instruments, etc., can solve the problems of magnetorheological fluid shear strain rate limitation, transmission error, measurement result deviation, etc. Links and human errors, ensuring stability and reliability, and the effect of stable and reliable linear errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

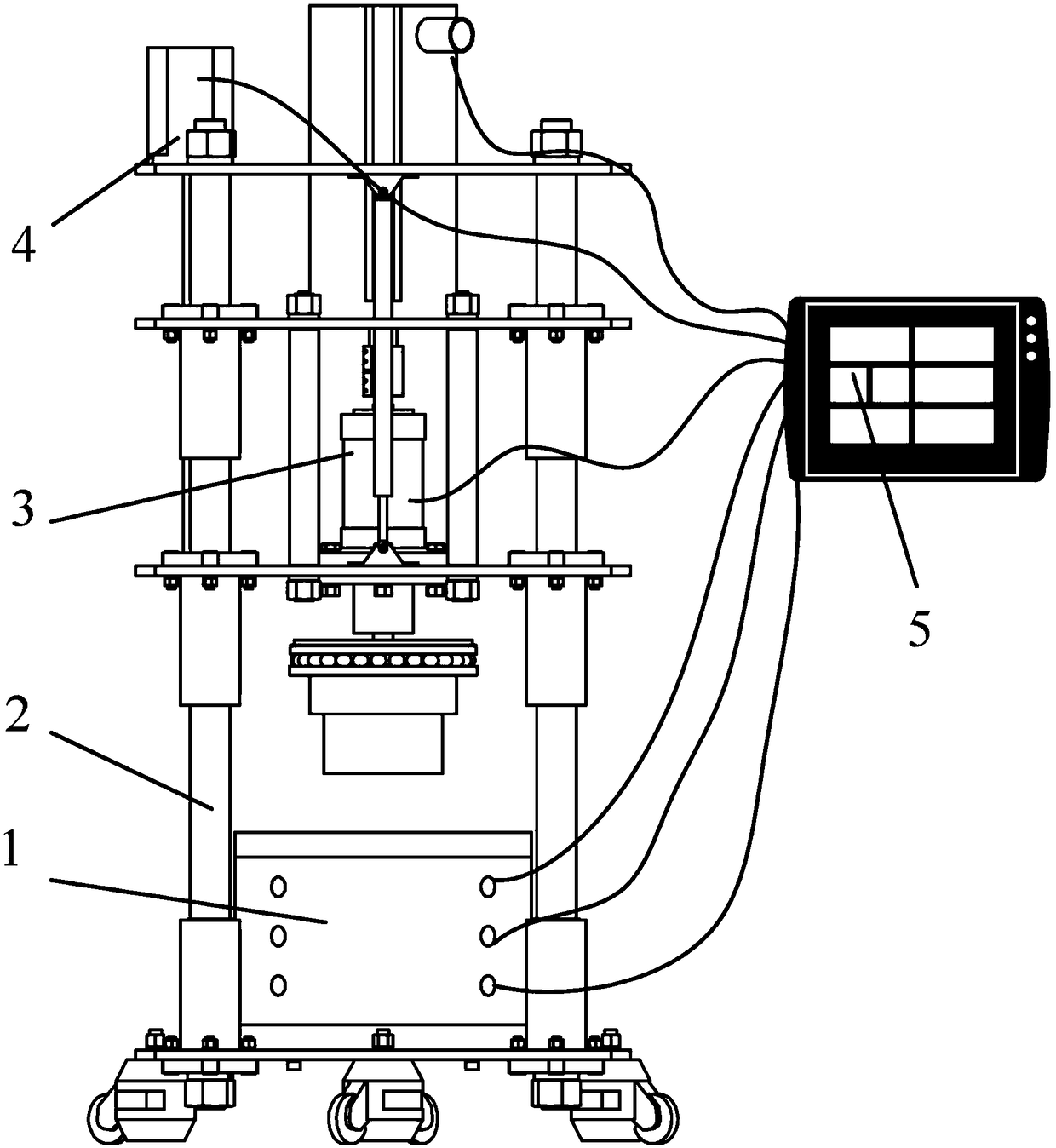

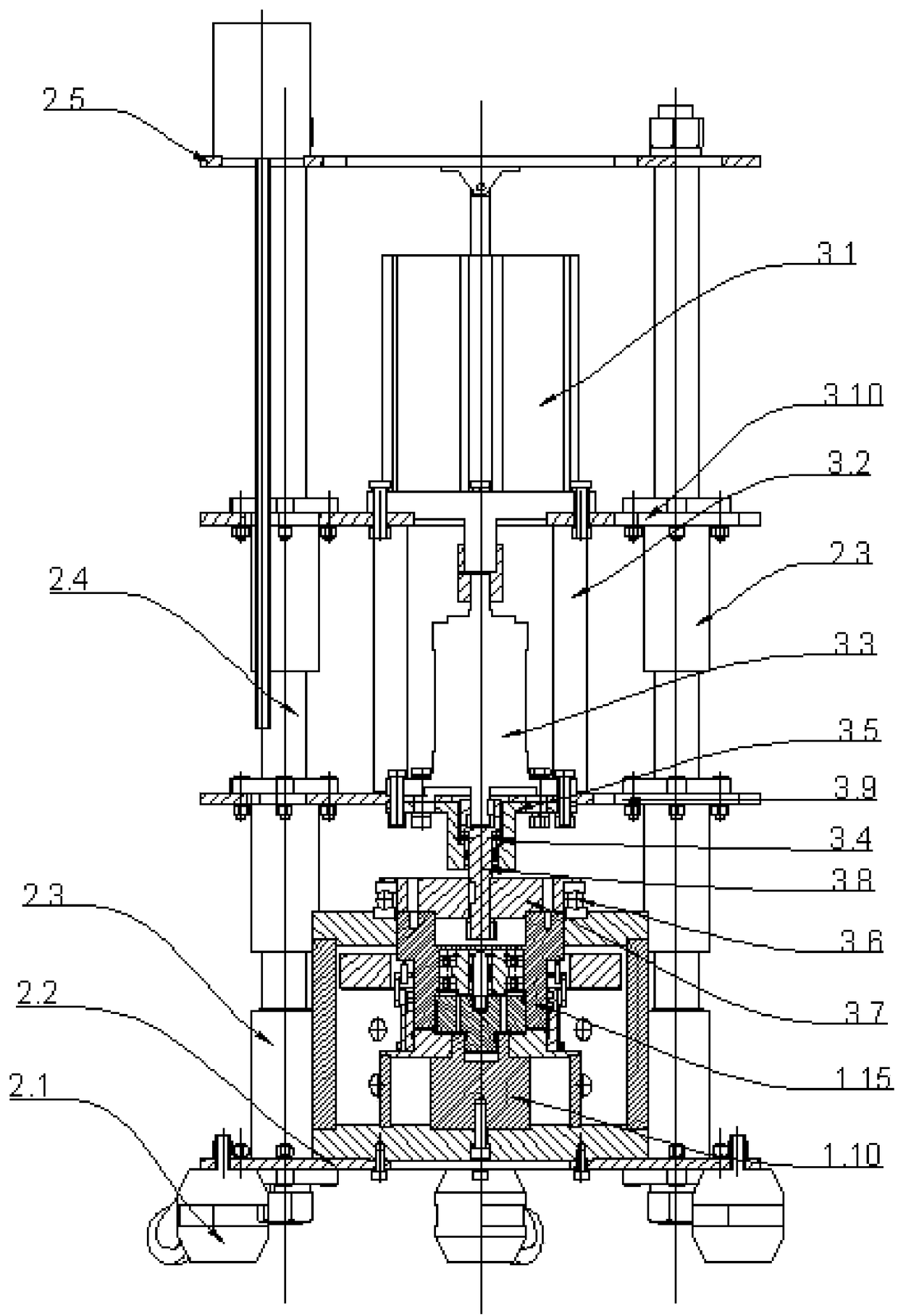

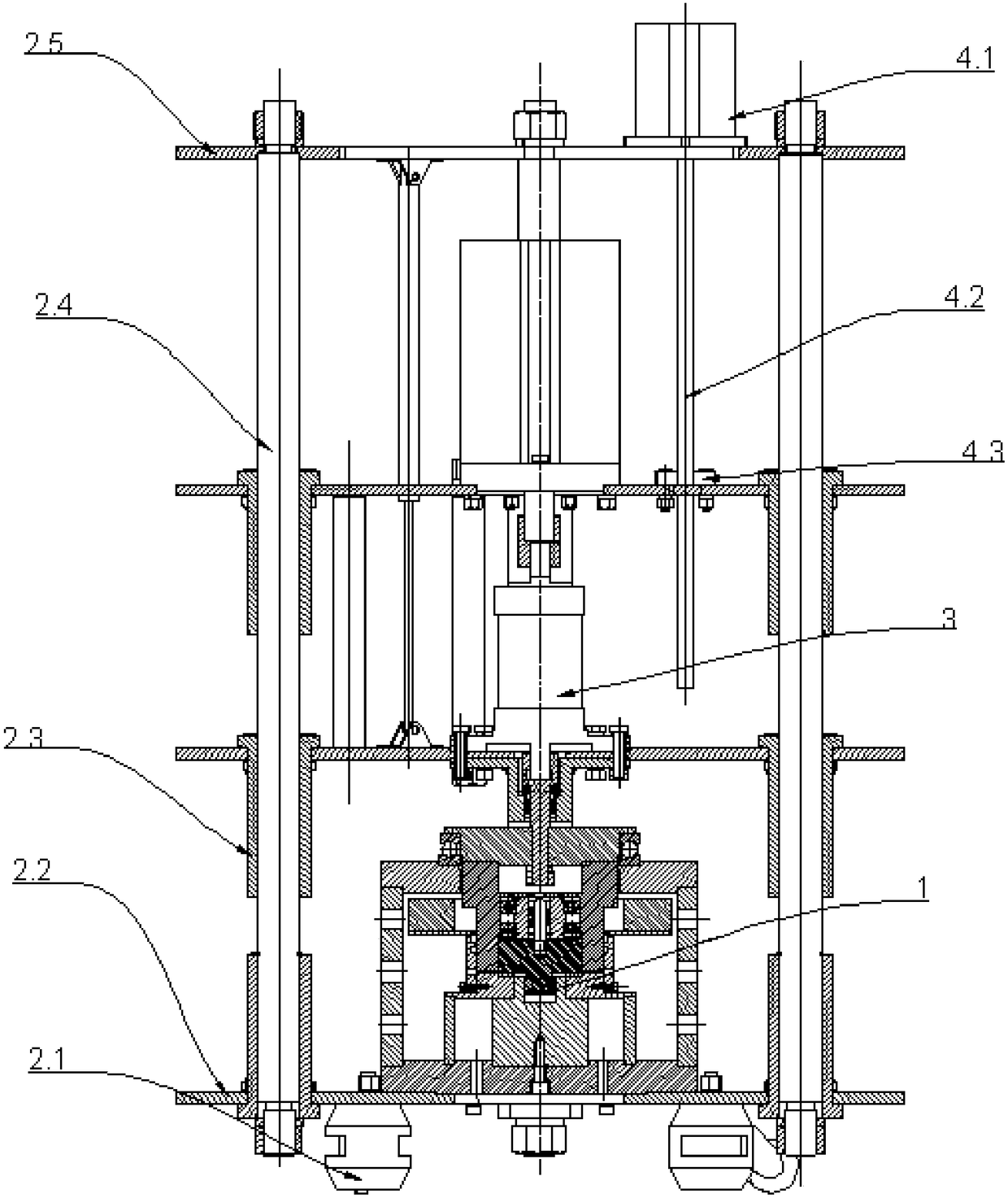

[0033] Such as Figure 1 to Figure 5 As shown, a magneto-rheological fluid characteristic tester includes a shearing device 1, a frame device 2, a transmission device 3, a lifting device 4, and a control measuring device;

[0034]The shearing device 1 includes a magnetic circuit device and a magnetorheological fluid 1.20, wherein the magnetic circuit device includes a shell composed of a magnetic circuit bottom plate 1.7, a magnetic circuit outer wall 1.2 and a magnetic circuit board 1.1, and an upper magnetic core 1.15 and a lower magnetic core are arranged in the shell. A magnetic core, the outer periphery of the magnetic core is provided with a magnetic isolation ring 1.5, the upper end of the magnetic isolation ring 1.5 is equipped with a coil mounting bracket 1.4, and the coil 1.3 is set outside the upper magnetic core 1.15 and placed on the coil mounting bracket 1.4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com