Liquid crystal panel and manufacturing method thereof

A technology of liquid crystal panels and manufacturing methods, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of not meeting the precision requirements of the dispensing process, expensive dispensing equipment, and poor consistency, so as to improve the visual effect and viewing experience. Avoiding the circuit printing process and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

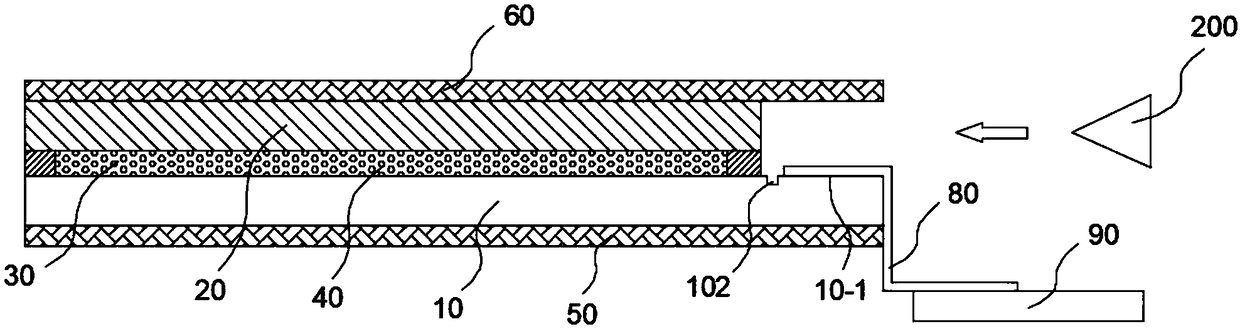

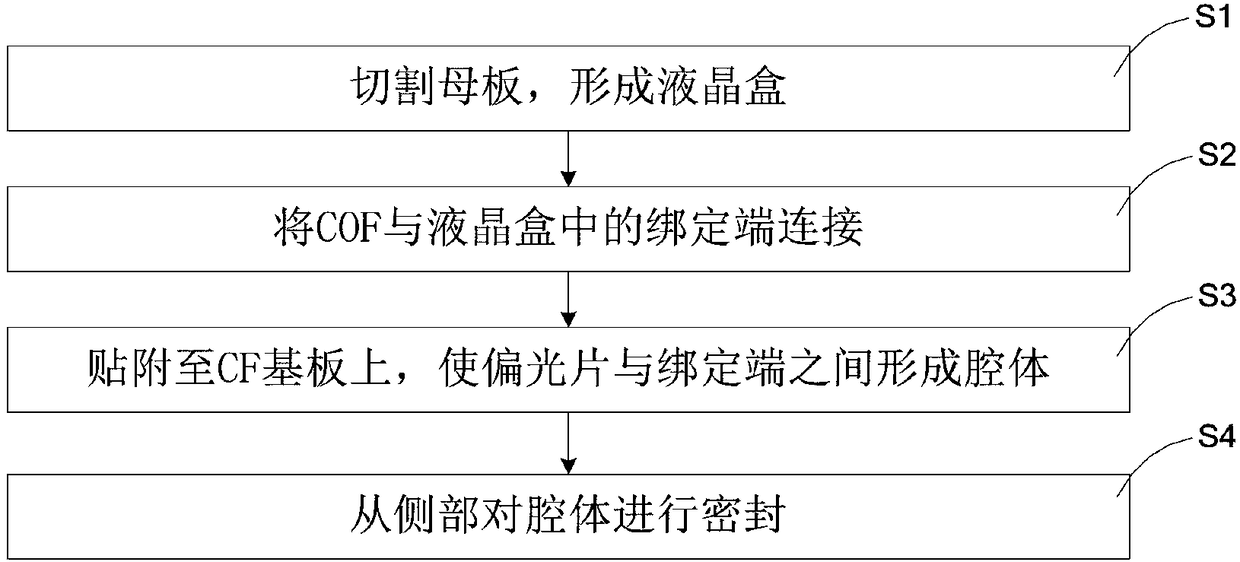

[0040] see figure 1 and figure 2 A liquid crystal panel provided in Embodiment 1 includes a TFT (Thin Film Transistor, thin film transistor) substrate 10 opposite to the backlight module, and a CF (Color filter, color filter) substrate disposed on the TFT substrate 10 20, and the liquid crystal 40 arranged between the TFT substrate 10 and the CF substrate 20, the liquid crystal 40 can be encapsulated between the TFT substrate 10 and the CF substrate 20 through the sealant 30, and the outer surfaces of the TFT substrate 10 and the CF substrate are respectively attached with The second polarizer 50 and the first polarizer 60 .

[0041] Wherein, each side of the CF substrate 20 covered on the sealant 30 is flush with each side of the sealant 30, it can be understood that the area where the liquid crystal 40 is provided forms the display area of the liquid crystal panel; In the setting of the fixed end, at least one end surface of the TFT substrate 10 exceeds the end surface ...

Embodiment 2

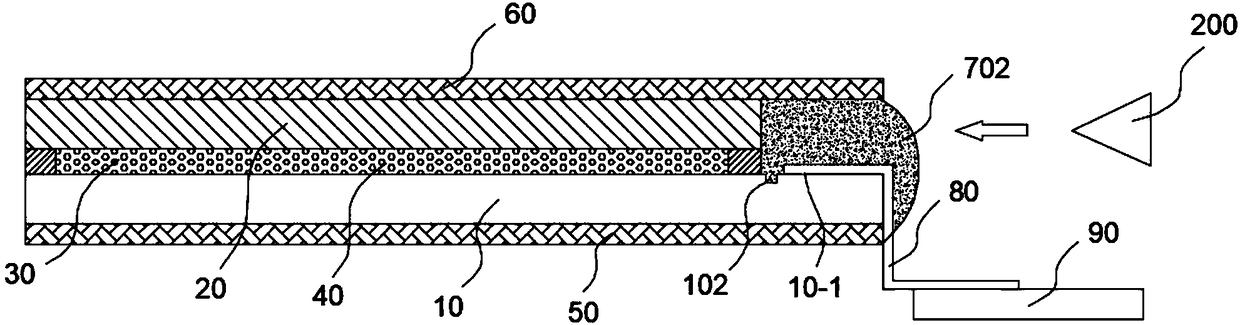

[0056] When the binding end 10-1 on the TFT substrate 10 is wider, if the filling method in Embodiment 1 is selected, the cavity between the first polarizer 60 and the binding end 10-1 cannot be fully filled. Therefore, This embodiment is a further improvement on the filling method in Embodiment 1. The difference between this embodiment and Embodiment 1 is that the filling method of the encapsulant is different. For other structures, you can refer to the scheme in Embodiment 1. Let me repeat.

[0057] Specifically, see Figure 4 , Figure 5 and Figure 6 The filling method of the cavity of the liquid crystal panel in the second embodiment is as follows: firstly complete the melting and filling of the first encapsulant 701, that is, before attaching the first polarizer 60 on the CF substrate 20, the binding end 10- 1. Paste a thermoplastic adhesive film on top, and then hot press when attaching the first polarizer 60 to melt and solidify the thermoplastic adhesive film to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com