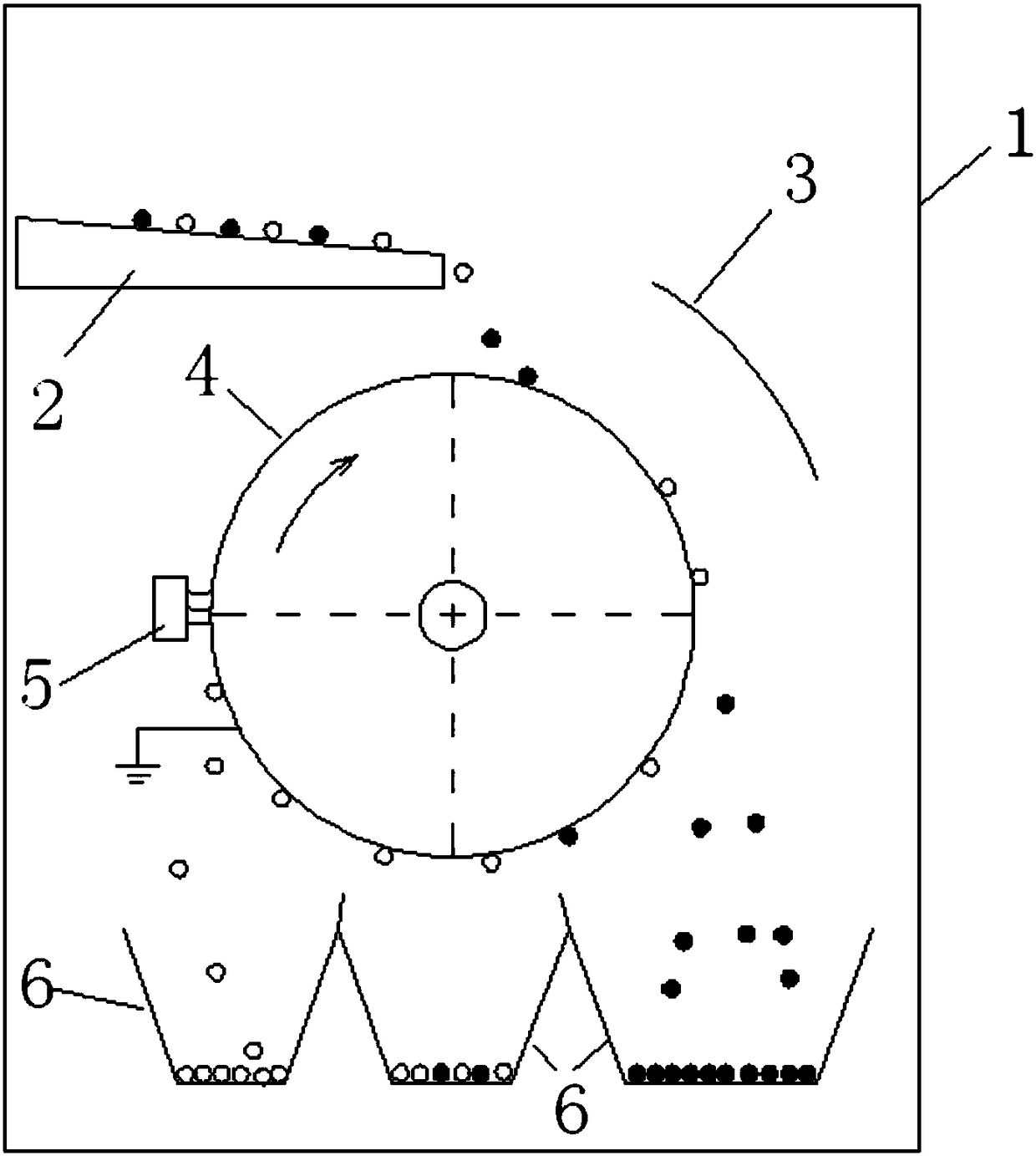

Micro-plastic extraction device based on electrostatic technology

A technology of microplastics and technology, which is applied in the field of microplastics extraction devices based on electrostatic technology, to achieve the effect of reducing workload, low cost and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

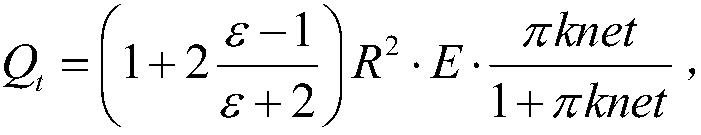

Method used

Image

Examples

example 1

[0034] Cut 10g of plastic film into small pieces of 5mm, mix it with 2000g of sand to make a mixed material, and drop the mixed material into the device for separation. It operates under the optimal process parameters, the input voltage is 5.5kV, and the rotation speed of the roller is 150rpm. After the operation, the materials in the three hoppers 6 are analyzed. In the left hopper 6, the sand content rate of plastic fragments is 1.44%, the sand in the right hopper 6 does not contain microplastic fragments, and the middle hopper 6 is mainly sand, and the ratio of plastic fragments is 12%. The material in the intermediate hopper 6 is separated again, and the ratio of plastic fragments drops to 3%, and the separation effect is good.

example 2

[0036]Mix 1g of polyethylene, polyvinyl chloride and polypropylene fragments with a size of less than 5mm with 2000g of fine sand, add the mixture from the feeder 2 to the device for separation, operate under the above-mentioned optimal process conditions, the mixture of the intermediate hopper 6 The material was reprocessed three times. Finally, the sand content in the left hopper 6 is 1.02%. The final plastic debris ratio of the mixed material in the middle is 2.24%, and there is no plastic debris in the right hopper 6, and the separation effect is good.

example 3

[0038] Put 2000g of environmental sediment samples into the device for separation, and adjust the parameters of the high-voltage composite electrode 3 and the roller electrode 4 to achieve the optimal process, and separate the mixed material in the intermediate hopper 6 for many times. Finally, 0.13g of plastic fragments were separated, and the proportion of plastic fragments in the intermediate material was 3.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com