A method and system for temperature-controlled stacking and heat dissipation of biomass fuel in an open-air stockyard

A technology of biomass fuel and open-air stockyard, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of large manpower and material resources, reduce management complexity, and save manpower and material resources , Optimize the effect of personnel and equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

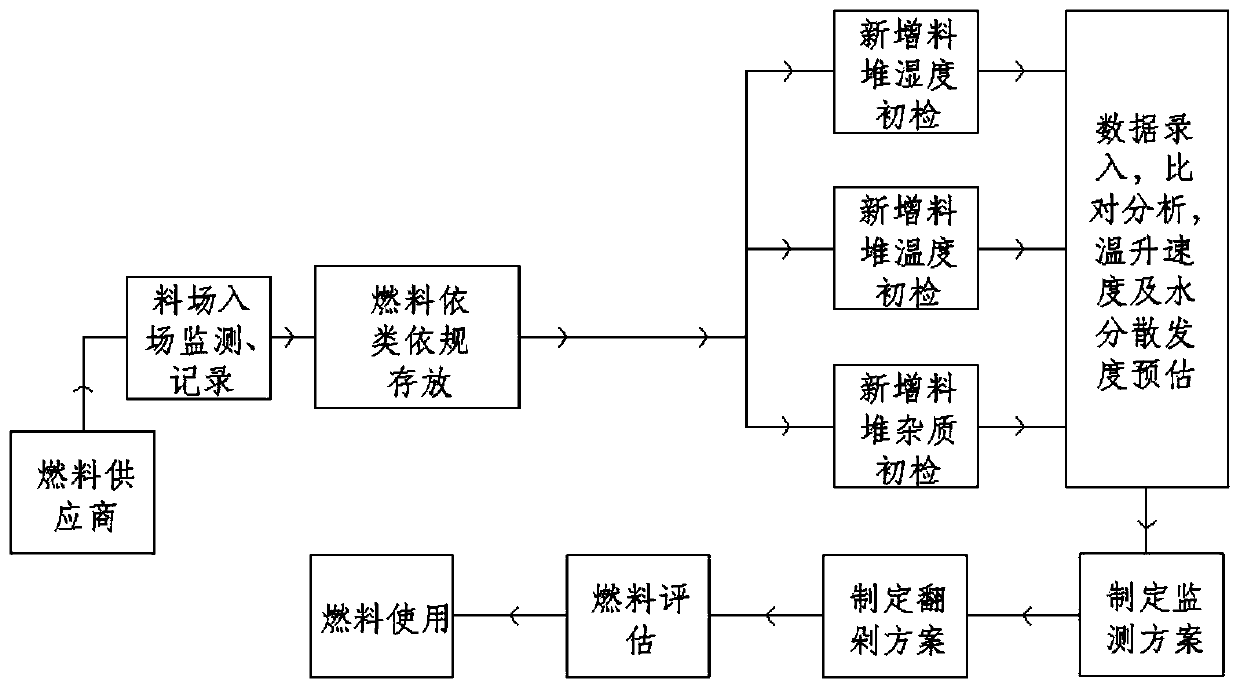

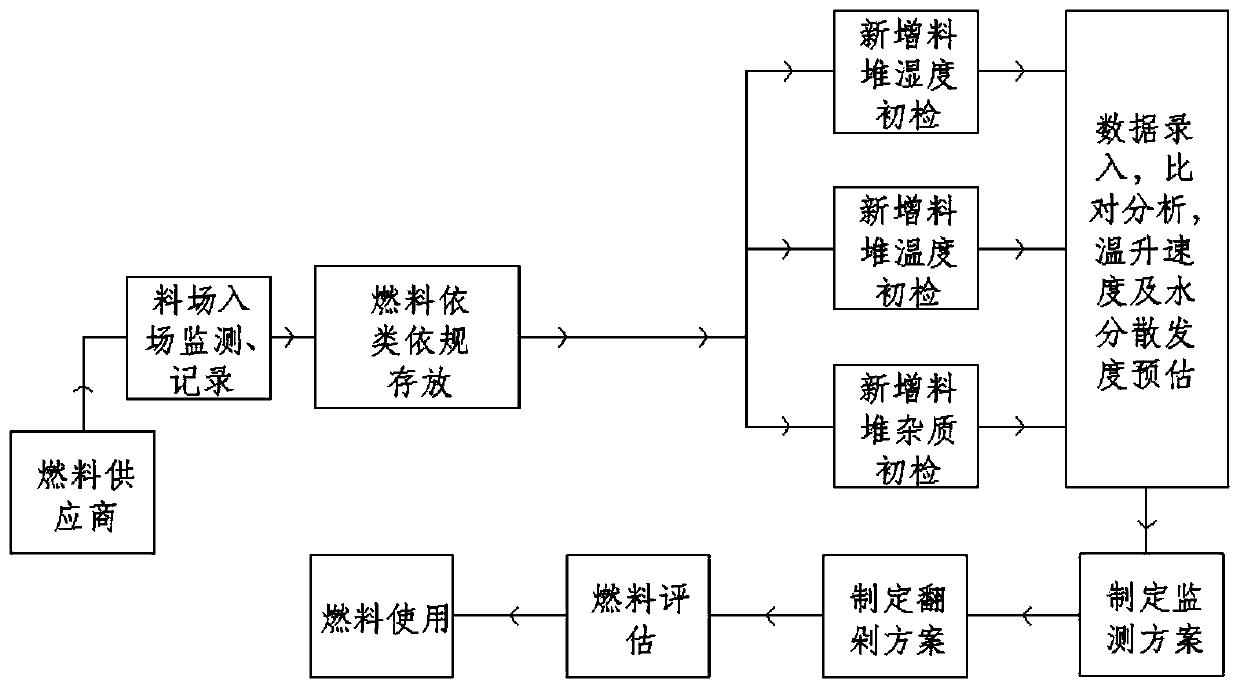

[0045] This embodiment discloses a method for temperature-controlled stacking and heat dissipation of biomass fuel in an open-air stockyard, such as figure 1 shown, including the following steps:

[0046] Step 1: Monitor and record the entry of fuel, and stack it according to regulations and categories;

[0047] After the fuel supplier transports the fuel to the stockyard, it will monitor the transported fuel and make monitoring records, including fuel type, quantity, calorific value, water content, ash, etc., and make records;

[0048] According to the monitoring data, the newly collected fuel is stacked and stored according to the regulations.

[0049] Step 2: After the stockpile is stable, monitor the temperature and humidity of the center of the stockpile, and monitor the surrounding environmental data at the same time;

[0050]After the stacking is completed and the stockpile is stable, the humidity of the fuel stockpile is measured by air flow drying method, microwave ...

Embodiment 2

[0066] The purpose of this embodiment is to provide a system compatible with the temperature-controlled stacking and cooling method of the biomass field in the first embodiment.

[0067] As an example to achieve the above purpose, this embodiment provides a temperature-controlled stacking cooling system for biomass materials, including a client, a server, and multiple temperature sensors connected to the server for monitoring the center of the stockpile and the surrounding environment and multiple humidity sensors. The server includes a memory, a processor, and a computer program stored on the memory and operable on the processor. When the processor executes the program, the following steps are implemented:

[0068] (1) receiving the monitoring data sent by the temperature sensor and the humidity sensor;

[0069] (2) According to the preset estimation model, calculate the estimated time for the stockpile to heat up to the critical carbonization temperature;

[0070] (3) Opti...

Embodiment 3

[0079] The purpose of this embodiment is to provide a computer-readable storage medium.

[0080] A computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are performed:

[0081] (1) receiving the monitoring data sent by the temperature sensor and the humidity sensor, the monitoring data including the material pile center and the surrounding environment data;

[0082] (2) According to the preset estimation model, calculate the estimated time for the stockpile to heat up to the critical carbonization temperature;

[0083] (3) According to the estimated time, optimize the monitoring schedule of the central temperature of the stockpile before stacking, and carry out temperature monitoring reminders at the corresponding monitoring time;

[0084] (4) Determine the stacking time according to the acquired monitoring data, and carry out stacking reminders at the corresponding stacking time;

[0085...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com