New energy vehicle battery pack heat-dissipating device

A new energy vehicle and cooling device technology, applied to battery pack parts, batteries, secondary batteries, etc., can solve the problems of high cost, poor heat dissipation performance, etc., to improve service life, high heat dissipation efficiency, and speed up air circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

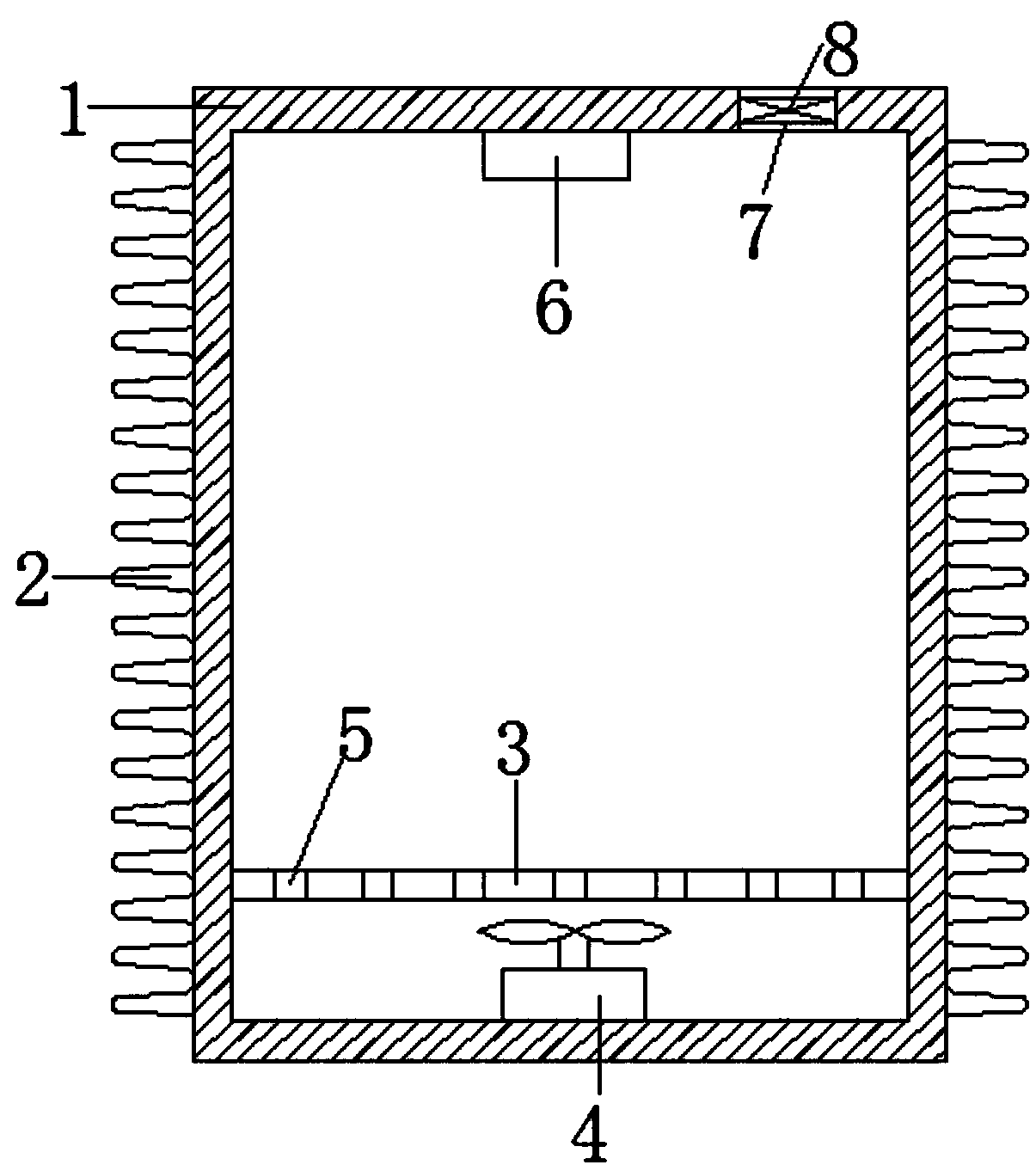

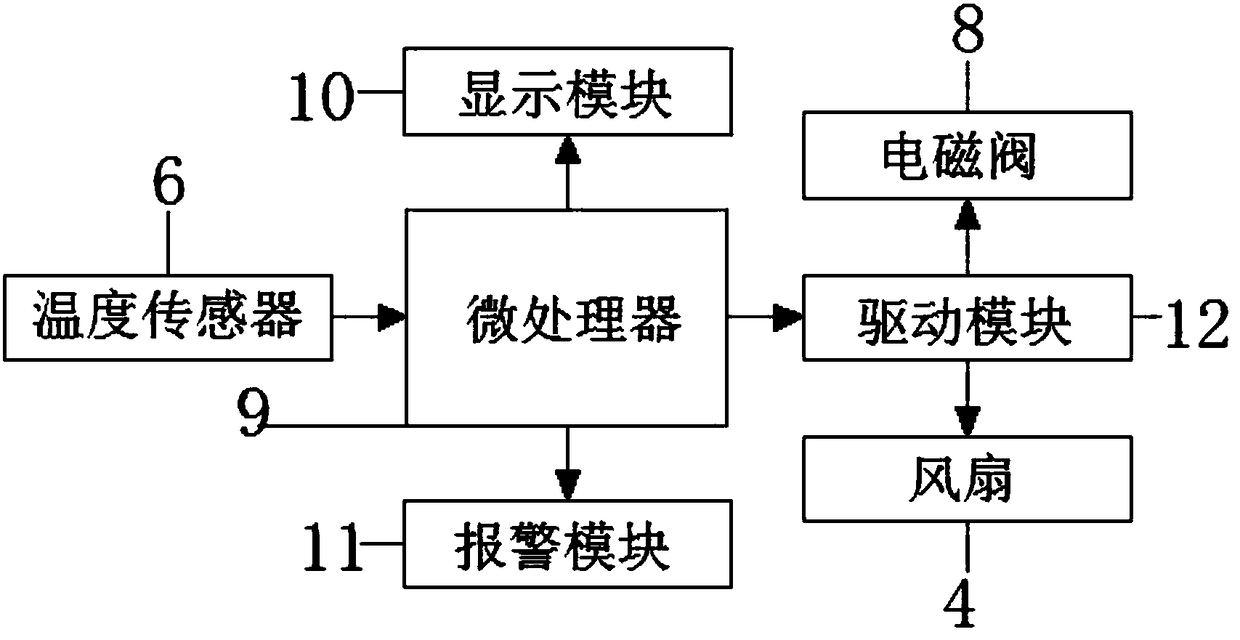

[0018] The new energy vehicle battery pack cooling device includes a box body 1, the left and right sides of the box body 1 are evenly provided with cooling fins 2, the bottom of the inner cavity of the box body 1 is provided with a fan 4 and a partition 3, and the partition The plate 3 is located above the fan 4, the partition 3 is evenly opened with through holes 5, the top of the inner cavity of the box body 1 is provided with a temperature sensor 6, and the top right side of the box body 1 is opened with a vent 7 , the cavity of the vent 7 is provided with a solenoid valve 8, the output end of the temperature sensor 6 is electrically connected to the input end of the microprocessor 9, and the output end of the microprocessor 9 is electrically connected to the display module 10 respectively , the input terminals of the alarm module 11 and the driving module 12, the output terminals of the driving module 12 are electrically connected to the input terminals of the solenoid val...

Embodiment 2

[0022] In this embodiment, the diameter of the semicircular chamfer is 2.5 centimeters, the diameter of the semicircular transition part is 4 centimeters, the porosity of porous aluminum silicon carbide is 30%, aluminum, copper, manganese and titanium, the aluminum, copper , manganese and titanium are as follows: 90 parts of aluminum; 9 parts of copper; 1 part of manganese and 11 parts of titanium, and the rest are the same as in Example 1.

Embodiment 3

[0024] In this embodiment, the diameter of the semicircular chamfer is 1 cm, the diameter of the semicircular transition part is 3 cm, the porosity of the porous aluminum silicon carbide is 20%, aluminum, copper, manganese and titanium, the aluminum, copper , manganese and titanium are as follows: 80 parts of aluminum; 12 parts of copper; 2 parts of manganese and 11 parts of titanium, and all the other are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com