Painting device for valve body of valve

A technology for painting device and valve body, which is applied to devices for coating liquid on the surface, coating, cleaning by electrostatic method, etc., which can solve the problems of cleaning dead corners of air intermediates, unable to blow air, and unable to achieve intermediate cleaning. , to achieve the effect of enhancing the dust removal effect and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

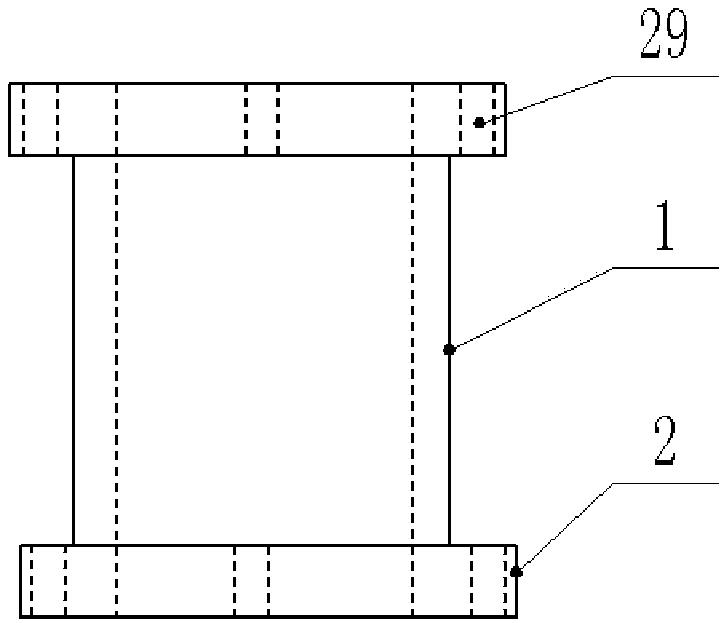

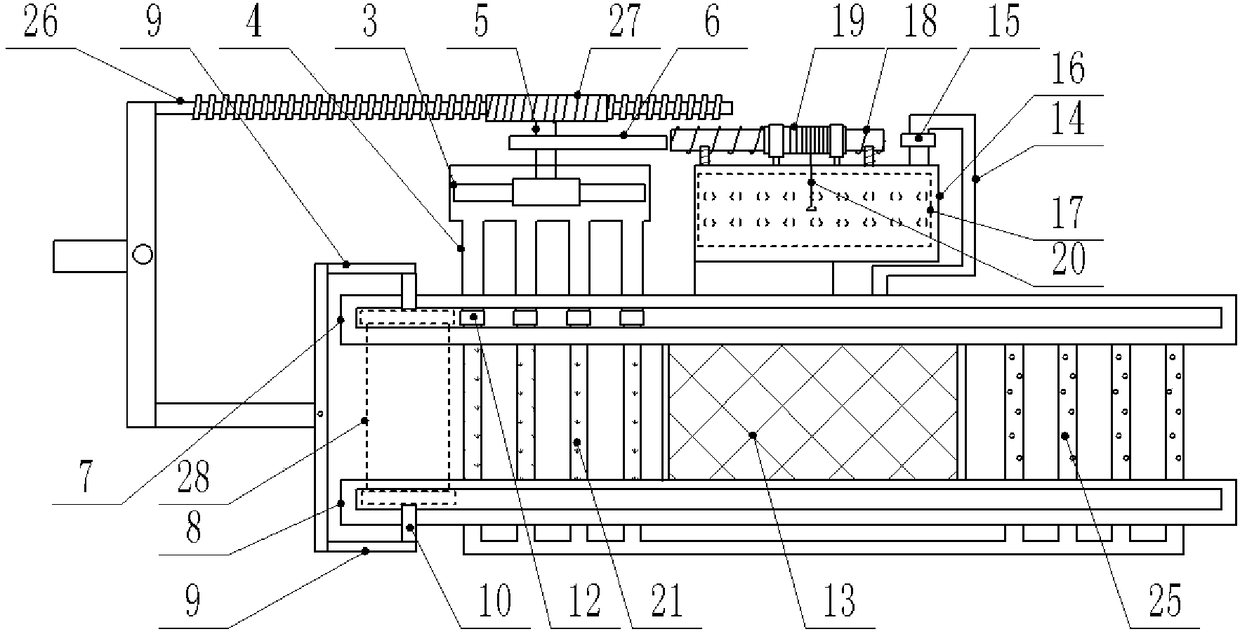

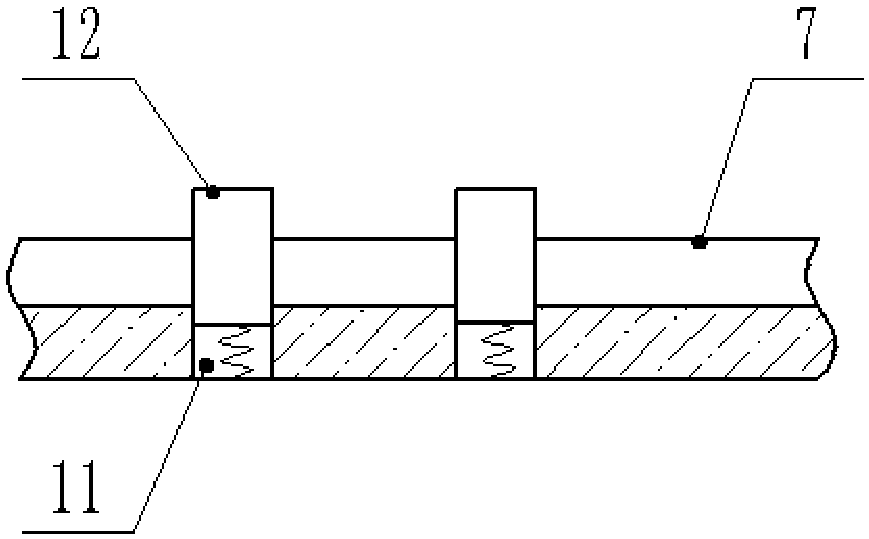

[0023] The reference signs in the drawings of the specification include: intermediate body 1, flange plate 2, fan 3, blowing pipe 4, rotating shaft 5, cam 6, first slide rail 7, second slide rail 8, slide arm 9, connector 10. Tank body 11, press block 12, paint tank 13, paint repair pipe 14, switch 15, paint repair box 16, slide plate 17, lead screw 18, lead screw pair 19, pull rope 20, dust removal pipe 21, through hole 22, bristle 23, elastic cord 24, paint-baking tube 25, worm screw 26, worm wheel 27, valve body 28, positioning hole 29.

[0024] Example figure 2 Shown: a painting device for a valve body, including a frame body, on which a first slide rail 7 and a second slide rail 8 parallel to each other are welded and fixed, and on the first slide rail 7 and the second slide rail 8 The sliding arm 9 is connected by sliding, and the connecting head 10 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com