High precision metal separator

A metal separator, high-precision technology, applied in the field of metal separators, can solve the problems of short service life, low separation accuracy, complex structure, etc., achieve the effect of removing skin effect, improving sensitivity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

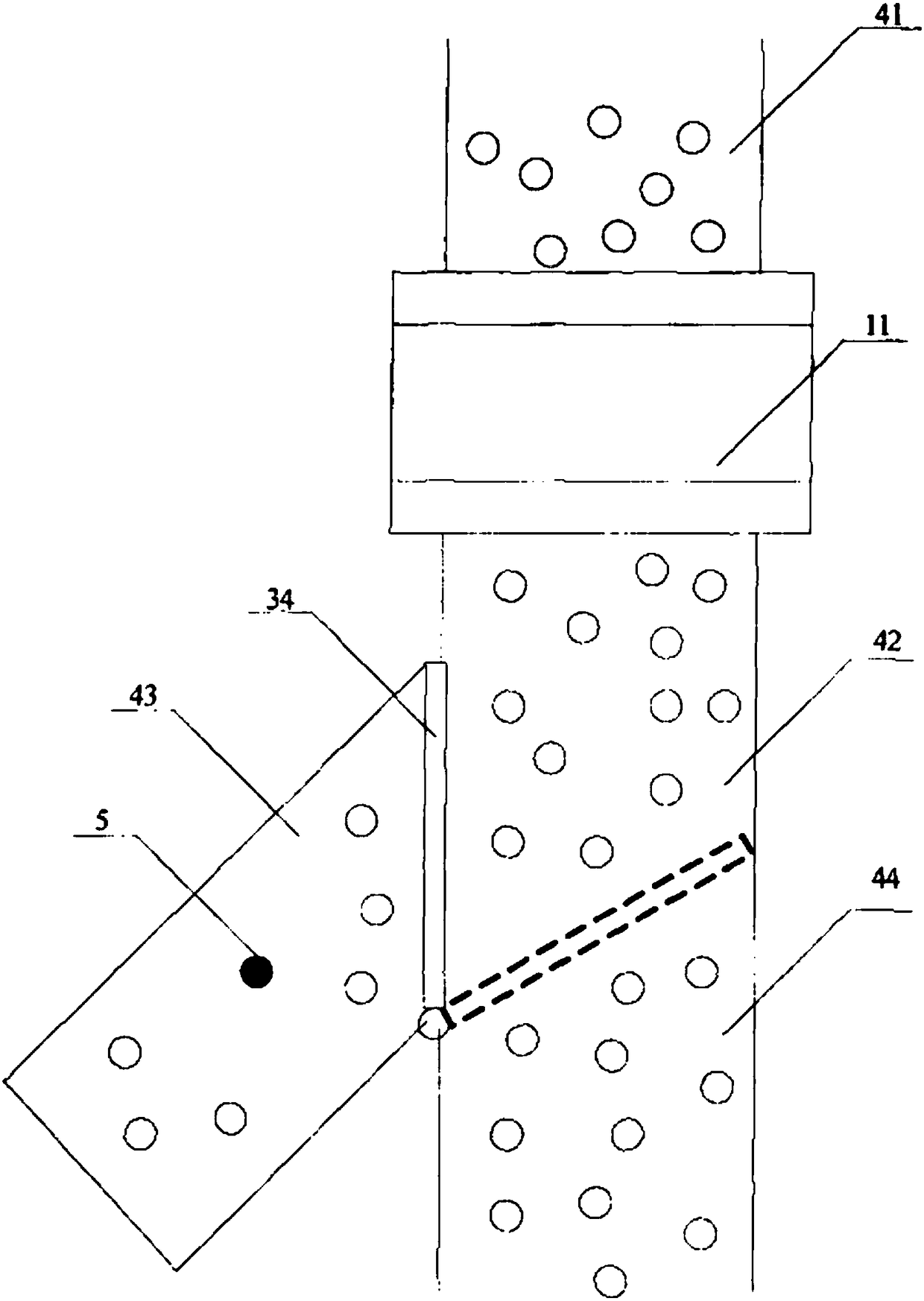

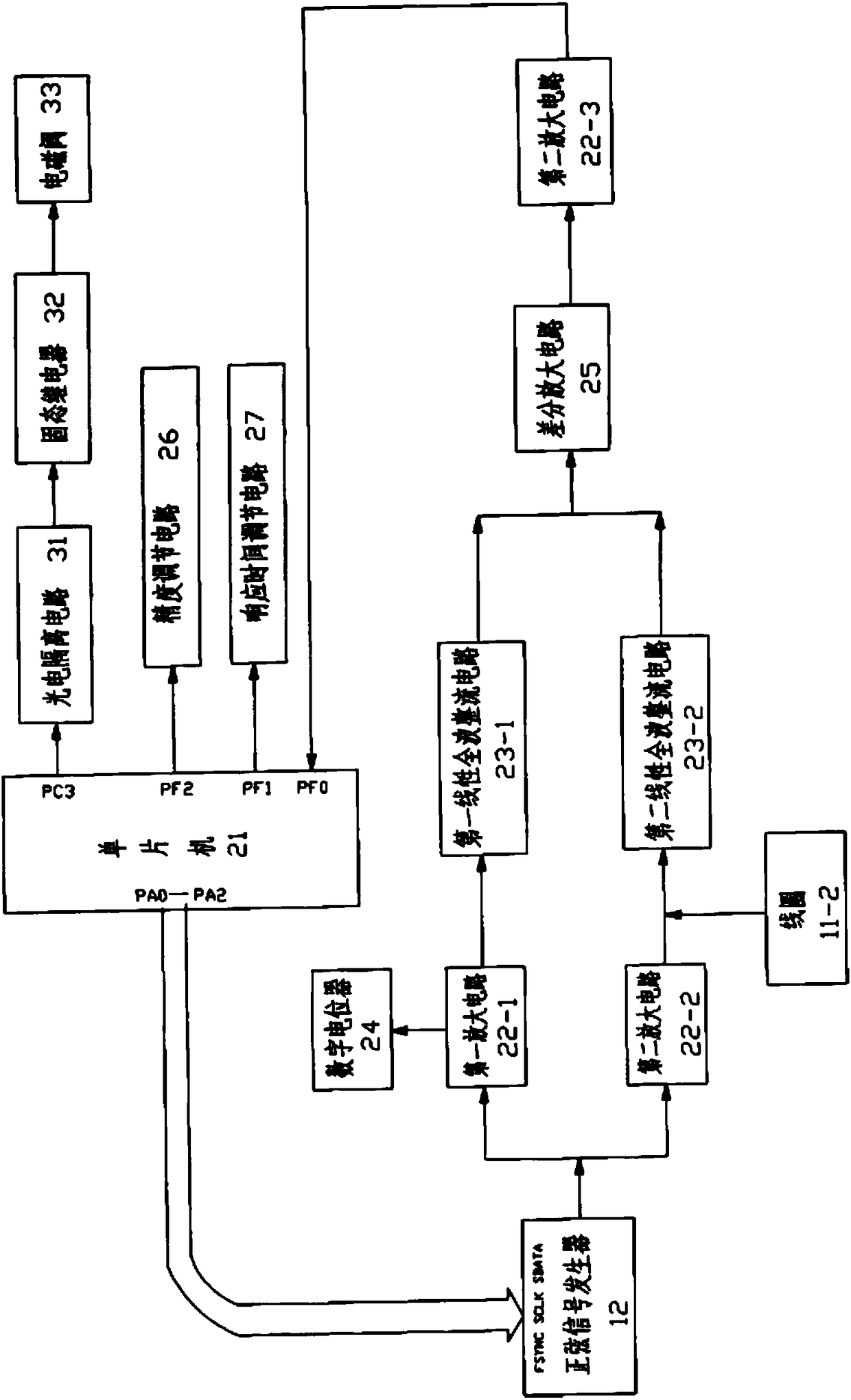

[0044] See Figure 1 to Figure 3 , the high-precision metal separator of this embodiment includes a detection module, a signal processing module, an execution module and a raw material transmission channel.

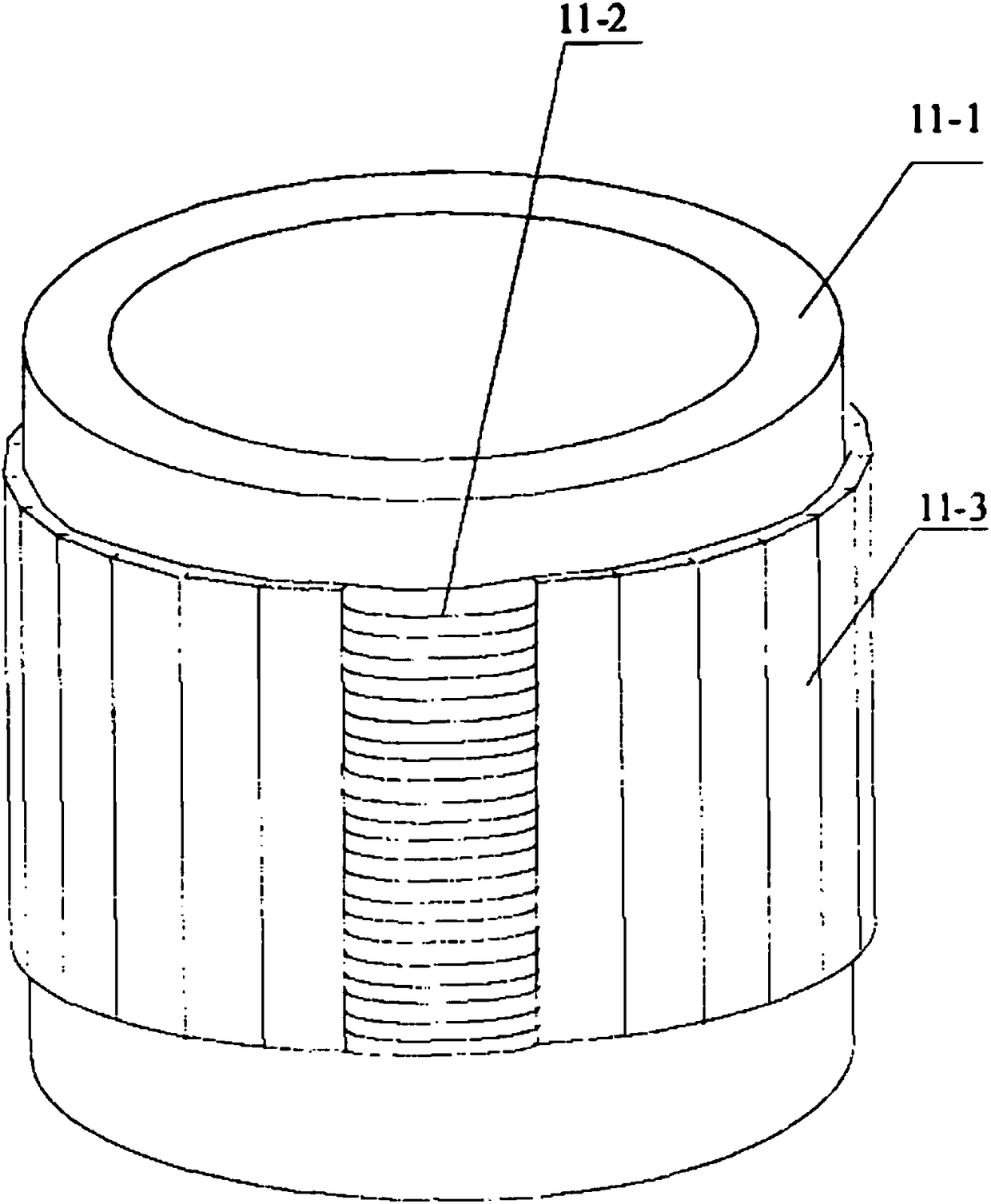

[0045] Wherein: the detection module includes a sensor 11 and a sinusoidal signal generator 12 . Sensor 11 see figure 2 , including an inner cylinder 11-1, a coil 11-2 and a magnetically permeable layer 11-3. A groove is provided in the middle of the outer surface of the inner cylinder 11; the coil 11-2 of the sensor 11 includes a transmitting coil and a receiving coil. The transmitting coil is an LC oscillating coil composed of 20 turns of multi-strand high-frequency wire and a precision capacitor, which is wound in the groove of the inner cylinder 11; the receiving coil is 2 turns of multi-strand high-frequency wire, which is wound outside the transmitting coil. The magnetically conductive layer 11-3 is fixed on the outer surface of the inner cylinder 11, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com