Noise-power-generation-based storage system for motor vehicle waste lead storage batteries and lead-containing parts

A waste lead battery and noise power generation technology, applied in the field of Internet of Things, can solve the problems of scattered layout, backward disposal facilities, waste that cannot meet the requirements of hazardous waste storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

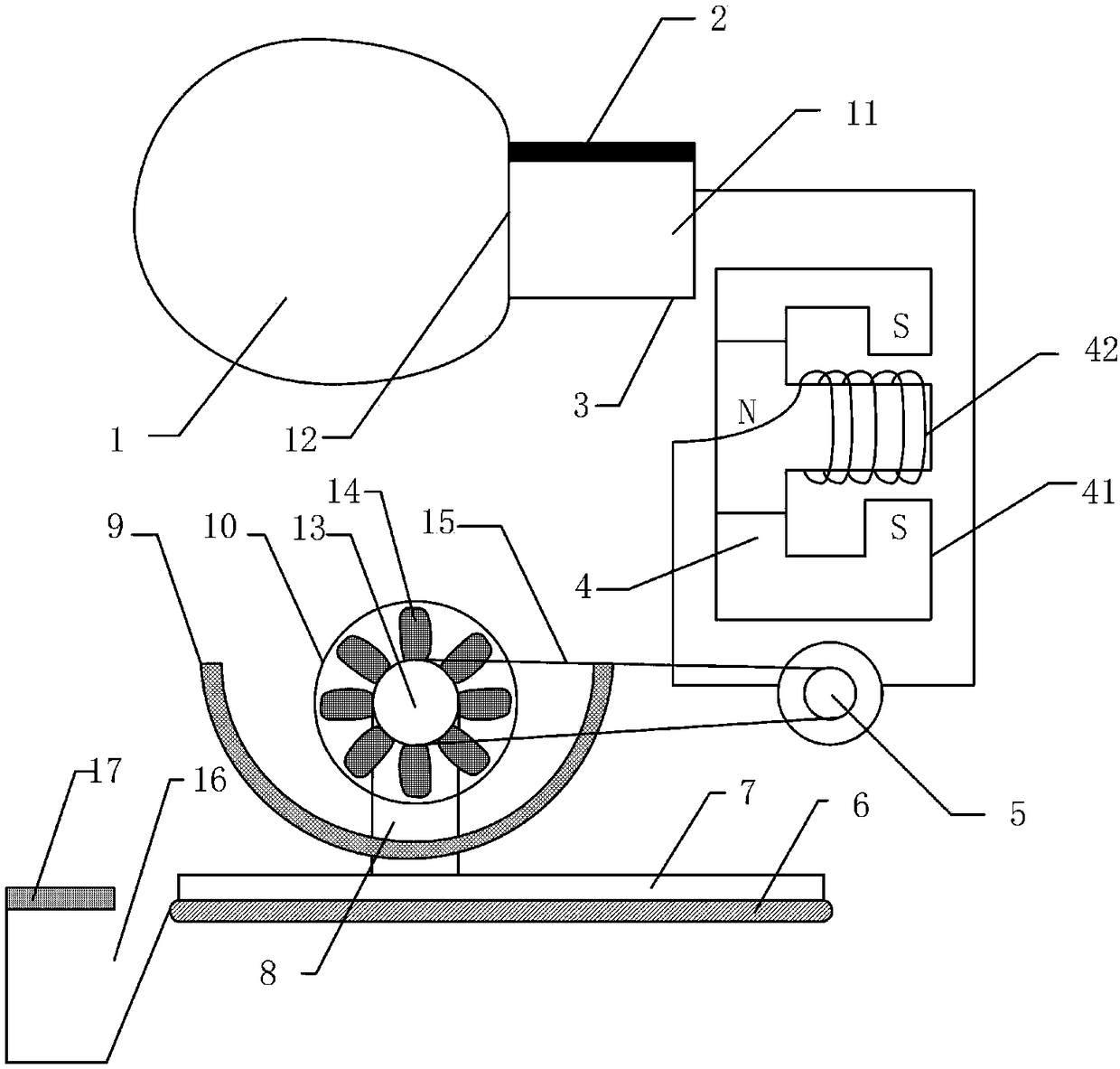

[0016] like figure 1 As shown, the vehicle waste lead-acid battery and lead-containing parts storage system based on noise power generation includes a resonator 1, a resonance cavity 11, a ring-shaped film 12, a rigid back plate 2, a piezoelectric ceramic film 3, a magnetic induction power generation mechanism 4, Permanent magnet 41, spring coil 42, driving device 5, transmission mechanism 6, tertiary filter 7, base 8, secondary filter 9, primary filter 10, linkage 13, crushing blade 14, linkage belt 15, Storage box 16 and dustproof mechanism 17;

[0017] The annular film 12 is arranged in the middle of the resonance cavity 11 to strengthen the vibration inside the cavity. One end of the spring coil 42 is connected to the piezoelectric ceramic film 3, and the other end is arranged in the magnetic field formed by the permanent magnet 41 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com