Tooth direction slope compensation method in toothed-wheel grinding process

A compensation method and technology of tooth orientation, applied to components with teeth, gear tooth manufacturing devices, gear teeth, etc., can solve the problems of gears not being ground, large differences, and tooth surfaces not being polished, and improve grinding accuracy , the steps are simple, and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0018] As shown in the figure, the compensation method for the slope of the tooth direction during the gear grinding process in this embodiment includes the following steps:

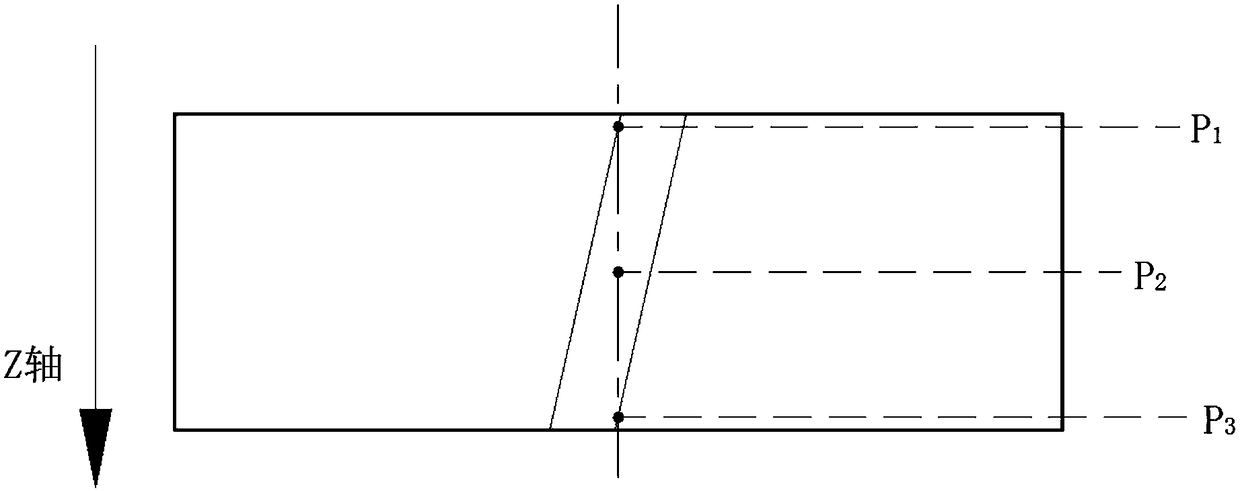

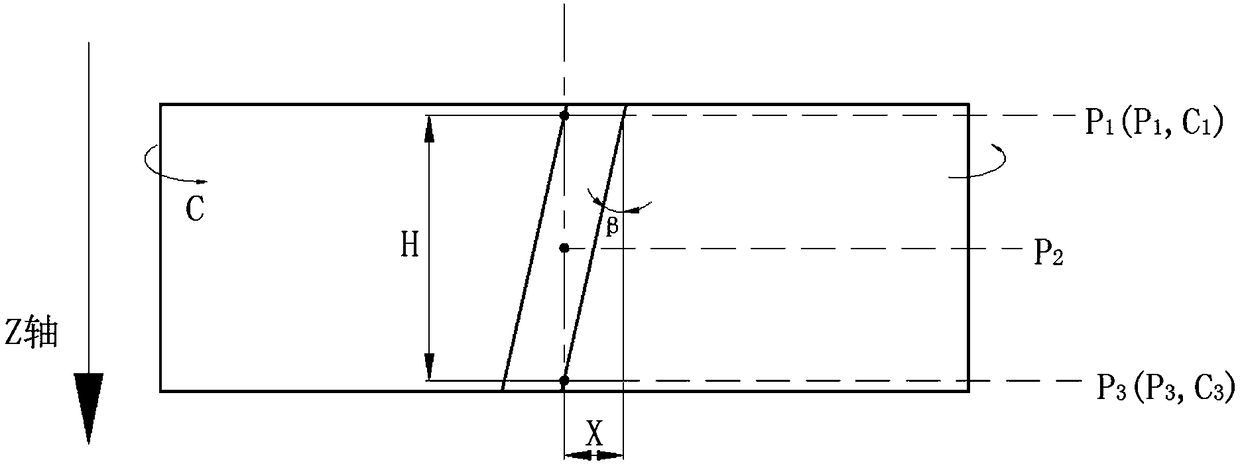

[0019] (1) After the first grinding (rough grinding) of the gear by the grinding wheel is completed, use the proximity switch set on the tool holder to read the center position P2 of a certain tooth groove on the current gear, and determine the corresponding position of P2 synchronously. P1 and P3 positions; said P1 and P3 are the corresponding intersection points of the vertical extension line passing through the P2 point on the current gear and the upper and lower groove lines of the tooth groove;

[0020] (2) Move the knife rest up and down along the gear width direction Z, and calculate the vertical distance H between the two points P1 and P3 through the program, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com