Test method for stone content in cement-stabilized crushed gravel

A cement stabilization and testing method technology, applied in the direction of weighing by removing certain components, can solve problems such as unqualified engineering quality, unqualified technology, and difficulty in judging, so as to improve quality control, accurate detection, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below:

[0026] Terms and Definitions:

[0027] Constant weight: After the first drying, cooling, and weighing, the constant weight is determined by continuous drying for 20 minutes each time, then cooling, and weighing. When the difference between two consecutive weighings is less than 0.01g, That is, a constant is reached.

[0028] Basic requirements for the test:

[0029] Number of tests and requirements: The number of tests for each determination is specified as two, and the average value of the two test results is used to express the measurement result.

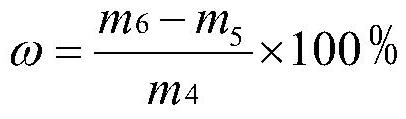

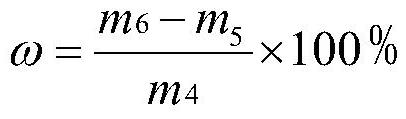

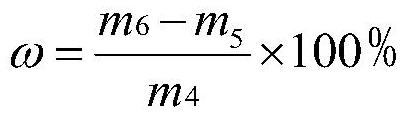

[0030] Representation of masses, volumes and results:

[0031] Use "gram (g)" to express mass, accurate to 0.01g. The analysis results are expressed in mass fractions, expressed in percent to two decimal places.

[0032] Reagents and materials: Unless otherwise specified, the reagents used should not be less than analytically pure. The water used should meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com