Testing device and testing method for wettability of lithium-ion battery separator

A lithium-ion battery and testing device technology, which is applied to measurement devices, secondary batteries, battery pack components, etc., can solve the problems of high camera accuracy, high cost, and increased battery resistance, and achieves a simple structure of the testing device and high testing efficiency. Simple method, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

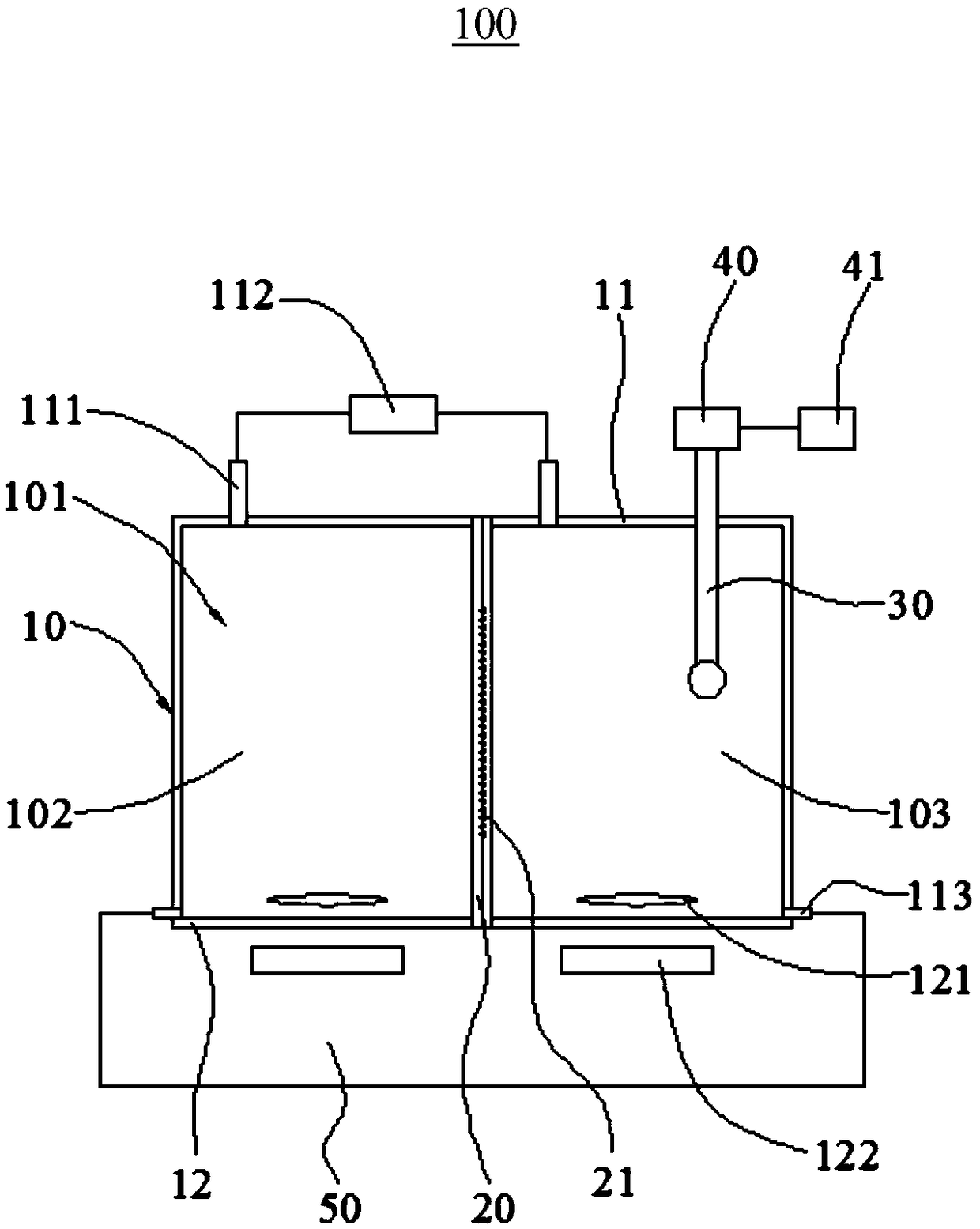

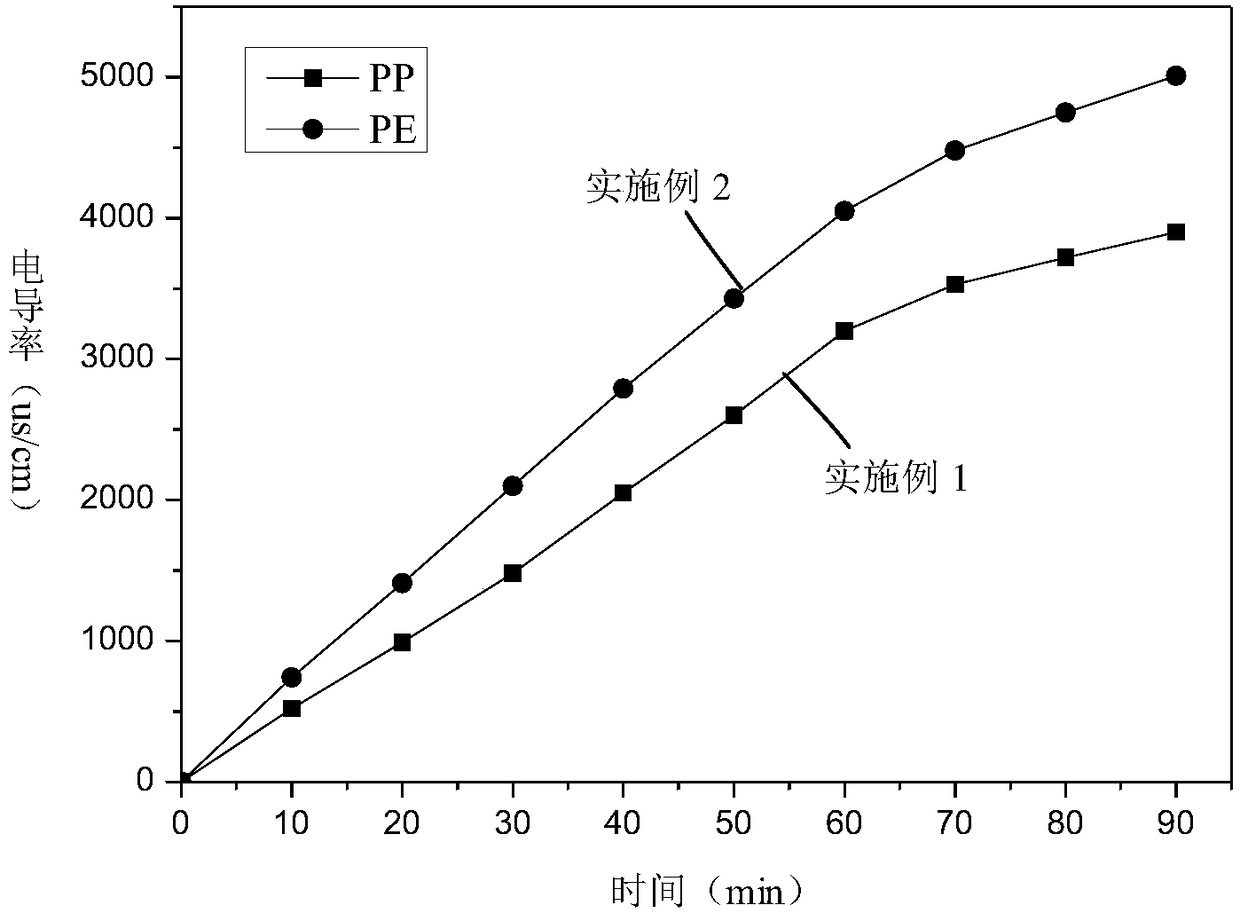

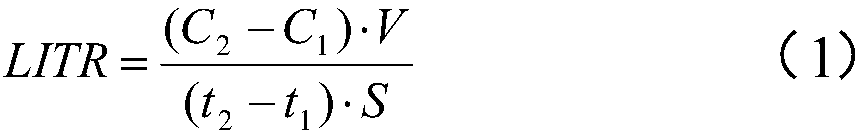

[0037] The shape of the central hollow of the clamping piece is rectangular, 100 mm long and 63.5 mm wide. The diaphragm sample (PP diaphragm) to be tested is fixed on the clamping piece, and the clamping piece 20 is clamped on the top wall 11 of the electrolyte container 10 and between the bottom wall 12; inject 500ml, 1mol / L LiPF6 (solvent is V(EC:DMC)=1:1) solution into the first storage tank, inject 500ml, V(EC: DMC) into the first storage tank DMC)=1:1 mixed solvent; turn on the magnetic stirrer, set the rotating speed to 200r / min, and set the temperature to 25°C; start the timer, record the conductivity of the initial solution in the second storage tank as 0 μs / cm, and then, Record the value of the conductivity every ten minutes for 1.5 hours, and draw the relationship curve of the conductivity with time.

[0038] The test results show that: at 1.5h, the conductivity is 3900μs / cm, and the lithium ion concentration in the second storage tank is measured every half hour by...

Embodiment 2

[0040] The shape of the central hollow of the clamping piece is rectangular, 100 mm long and 63.5 mm wide. The diaphragm sample (PE diaphragm) to be tested is fixed on the clamping piece, and the clamping piece 20 is clamped on the top wall 11 of the electrolyte container 10 and between the bottom wall 12; inject 500ml, 1mol / L LiPF6 (solvent is V(EC:DMC)=1:1) solution into the first storage tank, inject 500ml, V(EC: DMC) into the first storage tank DMC)=1:1 mixed solvent; turn on the magnetic stirrer, set the rotating speed to 200r / min, and set the temperature to 25°C; start the timer, record the conductivity of the initial solution in the second storage tank as 0 μs / cm, and then, Record the value of the conductivity every ten minutes for 1.5 hours, and draw the relationship curve of the conductivity with time.

[0041] The test results show that: at 1.5h, the conductivity is 50100μs / cm, and the lithium ion concentration in the second storage tank is measured every half hour b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com