Stacked spiral sludge dewatering machine

A technology of sludge dehydrator and dehydrator, which is applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc. It can solve the problems of dehydration waste, increased solid content, easy clogging, etc. , to achieve the effect of reducing design and construction costs, ensuring continuous and stable operation, and increasing water-passing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the embodiments. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

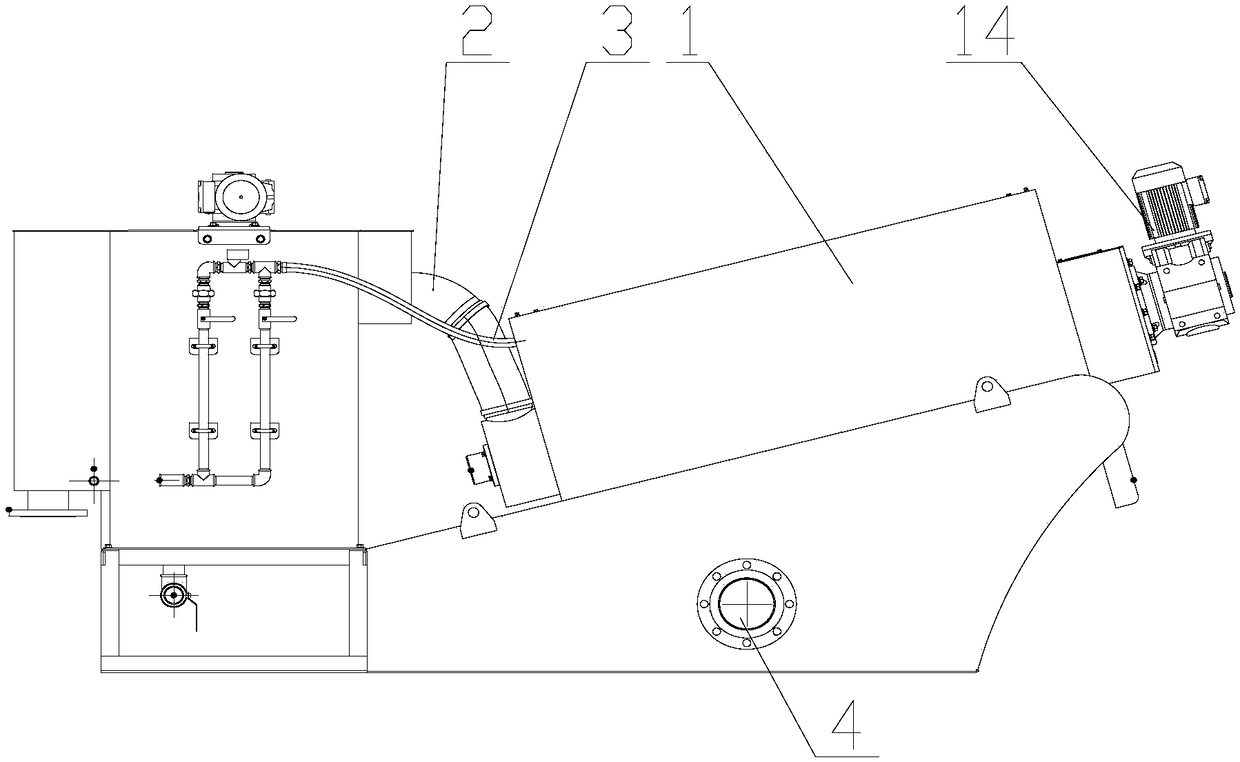

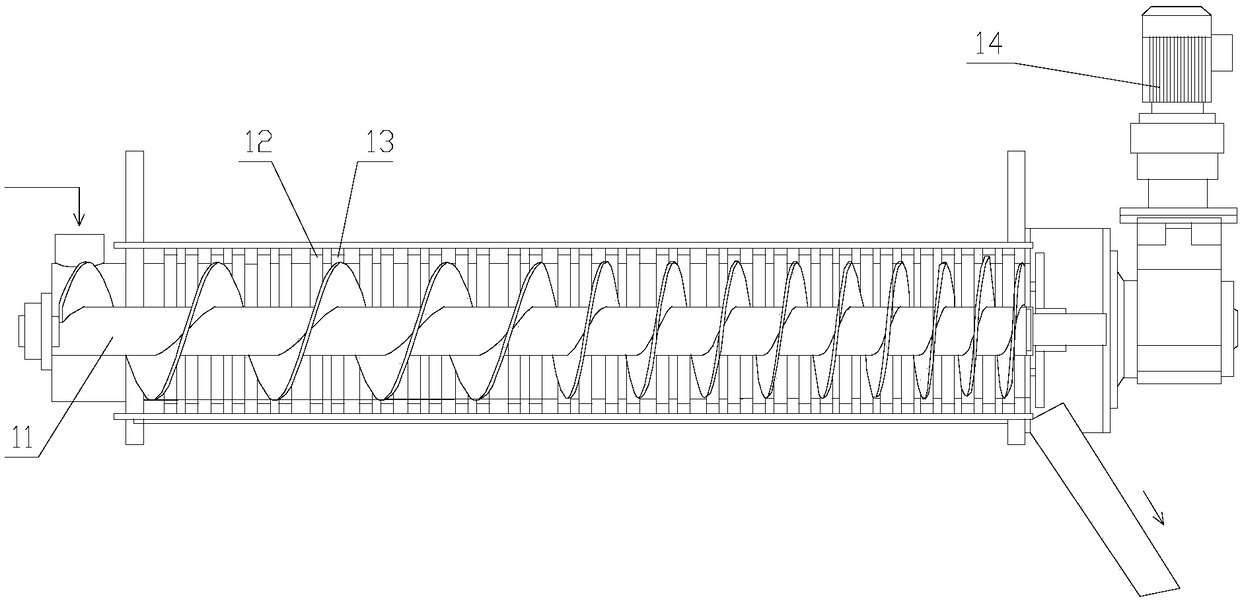

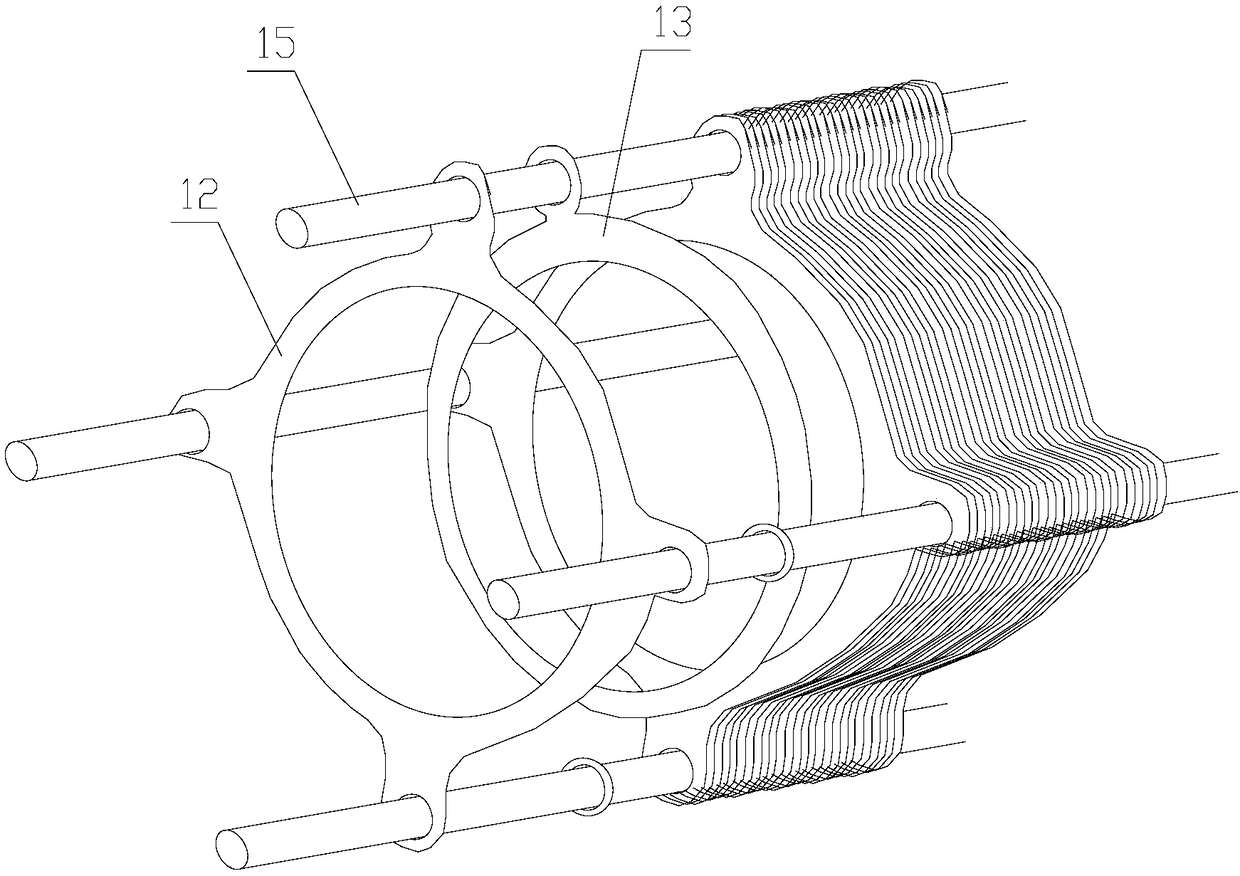

[0018] Such as figure 1 , 2 As shown in and 3, a screw stack sludge dehydrator includes a screw stack main body 1 which is inclined, and the screw stack body 1 includes a screw propeller 11 and a filter cartridge, and the screw propeller 11 is arranged in the filter cartridge; The screw pitch of the propeller 11 decreases along the propulsion direction; the filter cartridge is composed of a fixed ring 12 and a moving ring 13 stacked.

[0019] The inclined propeller 11 is adopted, especially the position of the inlet end connected to the mud inlet pipe 2 is relatively low, and the inclination angle is 15°-30°; the sludge can be dewatered to the greatest extent, and has a preliminary separation effect; The pitch of the shaft ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com