MDI prepolymer, preparation method thereof and synthetic method for two-component polyurethane elastomer

A synthesis method and prepolymer technology, applied in the field of chemical products, can solve the problems of slow curing molding speed, detachment of epidermis matrix, peeling, etc., and achieve the effects of improving pass rate and production efficiency, increasing molding speed, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

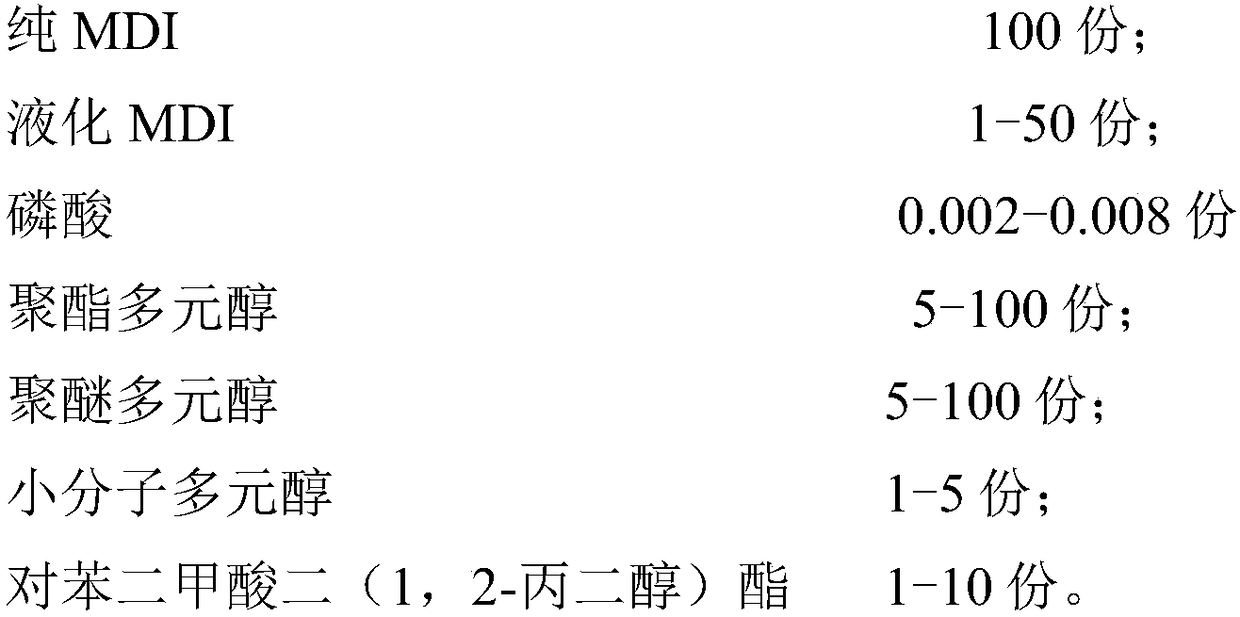

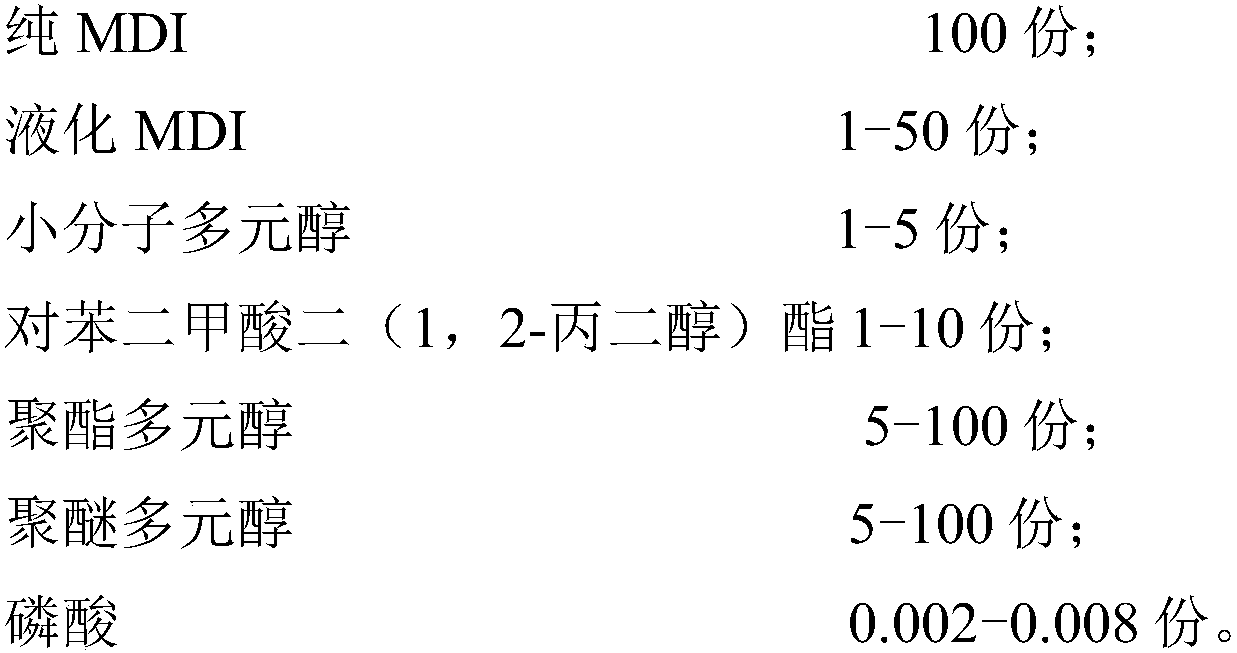

[0036] 1. Preparation of MDI prepolymer

[0037] (1) 100 parts by weight of pure MDI, 1 part by weight of liquefied MDI and 0.002 part by weight of phosphoric acid are added in the reactor simultaneously to mix and stir, and the temperature in the control reactor is 60-70 ℃;

[0038] (2) 5 parts by weight of polyester polyol and 5 parts by weight of polyether polyol are added to the reactor, and the temperature in the control reactor is 70-80 ° C, and reacted for 1-3 hours;

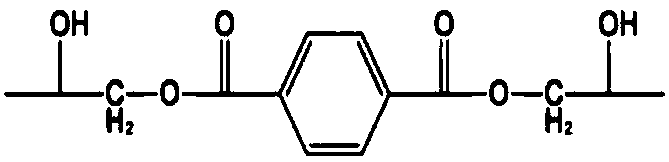

[0039] (3) adding 1 weight part of small molecular polyol, 1 weight part of terephthalic acid two (1,2-propylene glycol) ester in the reactor, the temperature in the control reactor is 60-70 ℃, reacted 1-3 hours , MDI prepolymers were obtained.

[0040] 2. Preparation of component A

[0041] Physically mix 100 parts by weight of polyester polyol, 0.1 part by weight of foaming agent, 0.1 part by weight of foam stabilizer, 1 part by weight of chain extender, and 0.5 part by weight of catalyst.

[0042] 3...

Embodiment 2

[0045] 1. Preparation of MDI prepolymer

[0046] (1) 100 parts by weight of pure MDI, 50 parts by weight of liquefied MDI and 0.008 parts by weight of phosphoric acid are added in the reactor simultaneously to mix and stir, and the temperature in the control reactor is 60-70 ℃;

[0047] (2) 100 parts by weight of polyester polyols and 100 parts by weight of polyether polyols are added to the reactor, and the temperature in the control reactor is 70-80 ° C, and reacted for 1-3 hours;

[0048] (3) 5 parts by weight of small molecular polyols, 10 parts by weight of two (1,2-propylene glycol) terephthalate are added in the reactor, the temperature in the control reactor is 60-70 ° C, and the reaction is 1-3 hours , MDI prepolymers were obtained.

[0049] 2. Preparation of component A

[0050] Physically mix 100 parts by weight of polyester polyol, 5 parts by weight of foaming agent, 2 parts by weight of foam stabilizer, 20 parts by weight of chain extender, and 3 parts by weight...

Embodiment 3

[0054] 1. Preparation of MDI prepolymer

[0055] (1) 100 parts by weight of pure MDI, 25 parts by weight of liquefied MDI and 0.005 parts by weight of phosphoric acid are added in the reactor simultaneously to mix and stir, and the temperature in the control reactor is 60-70 ℃;

[0056] (2) 30 parts by weight of polyester polyol and 30 parts by weight of polyether polyol are added to the reaction kettle, and the temperature in the control reaction kettle is 70-80 ° C, and reacted for 1-3 hours;

[0057] (3) 3 parts by weight of small molecular polyols, 5 parts by weight of two (1,2-propylene glycol) terephthalate are added in the reactor, the temperature in the control reactor is 60-70 ° C, and the reaction is 1-3 hours , MDI prepolymers were obtained.

[0058] 2. Preparation of component A

[0059] Physically mix 100 parts by weight of polyester polyol, 3 parts by weight of foaming agent, 1 part by weight of foam stabilizer, 10 parts by weight of chain extender, and 2 parts b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com