Re-leaching process for carbon refractory gold concentrate cyanide tailings

A technology for cyaniding tailings and refractory gold, applied in the direction of improving process efficiency, etc., can solve the problems of limited degradation, residue, and ineffective leaching of gold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

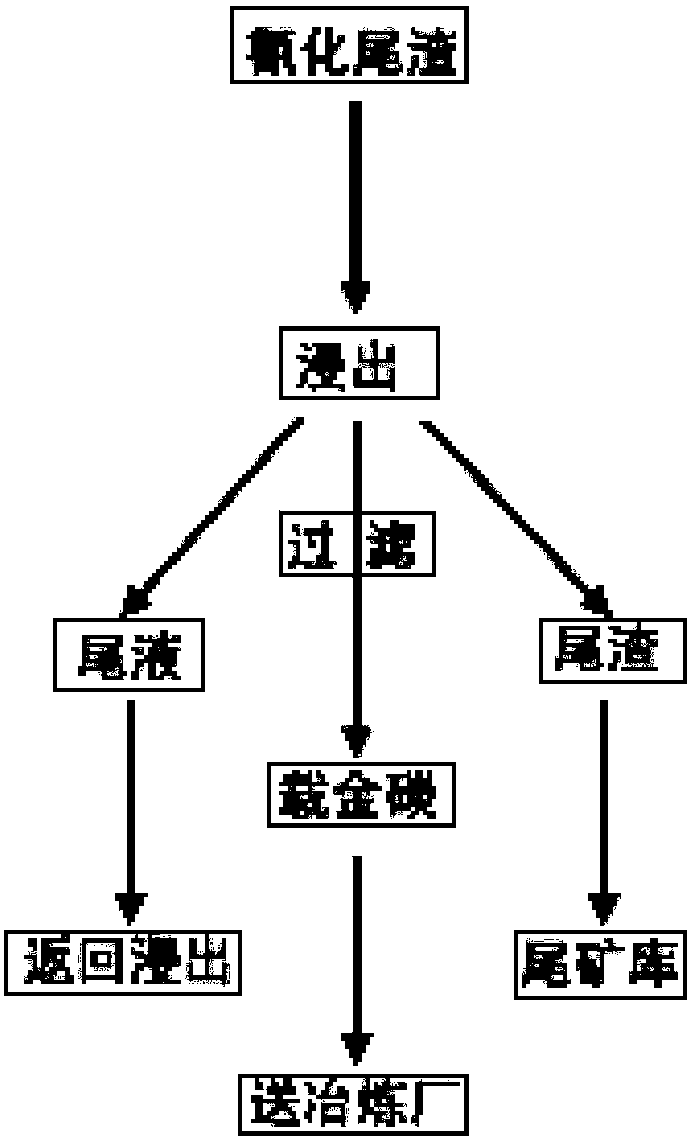

Image

Examples

Embodiment 1

[0017] A carbonaceous refractory gold concentrate in Guizhou, containing Au 16.78g / t, S 35.85%, As 1.47%, total carbon 2.42%, organic carbon 2.08%, direct cyanide carbon leaching gold leaching rate of gold concentrate is 10.24% , the cyanide carbon leaching gold leaching rate after biological pre-oxidation was 80.18%, and the gold content in cyanide tailings was 3.48g / t.

[0018] The cyanide tailings were slurried with water to form a solution with a liquid-solid ratio of 4:1, 10% CaO and 20g / L coconut shell activated carbon were added, and after leaching at 90°C for 8 hours, the leached residue contained 1.42g / t of gold , The leaching rate of gold in leaching slag is 59.20%, the rate of gold leaching in gold concentrate is 92.03%, and the rate of gold leaching is increased by 11.85%.

Embodiment 2

[0020] A carbonaceous refractory gold concentrate in Guizhou, containing 28.40g / t of Au, 21.36% of S, 1.93% of As, 3.18% of total carbon, 1.85% of organic carbon, and the direct cyanidation carbon leaching gold leaching rate of gold concentrate is 1.22% , the gold leaching rate of cyanide carbon leaching after biological pre-oxidation was 81.09%, and the gold content in cyanide tailings was 7.16g / t.

[0021] The cyanide tailings were slurried with water to form a solution with a liquid-solid ratio of 3:1, 5% CaO and 20g / L coconut shell activated carbon were added, and after leaching at 70°C for 6 hours, the leached residue contained 3.06g / t of gold , The leaching rate of gold in leaching slag is 57.26%, the rate of gold leaching in gold concentrate is 91.69%, and the rate of gold leaching is increased by 10.60%.

[0022] It can be seen that, through the above-mentioned technical scheme, the present invention can leach more than 50% of the gold through the releaching of the cya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com