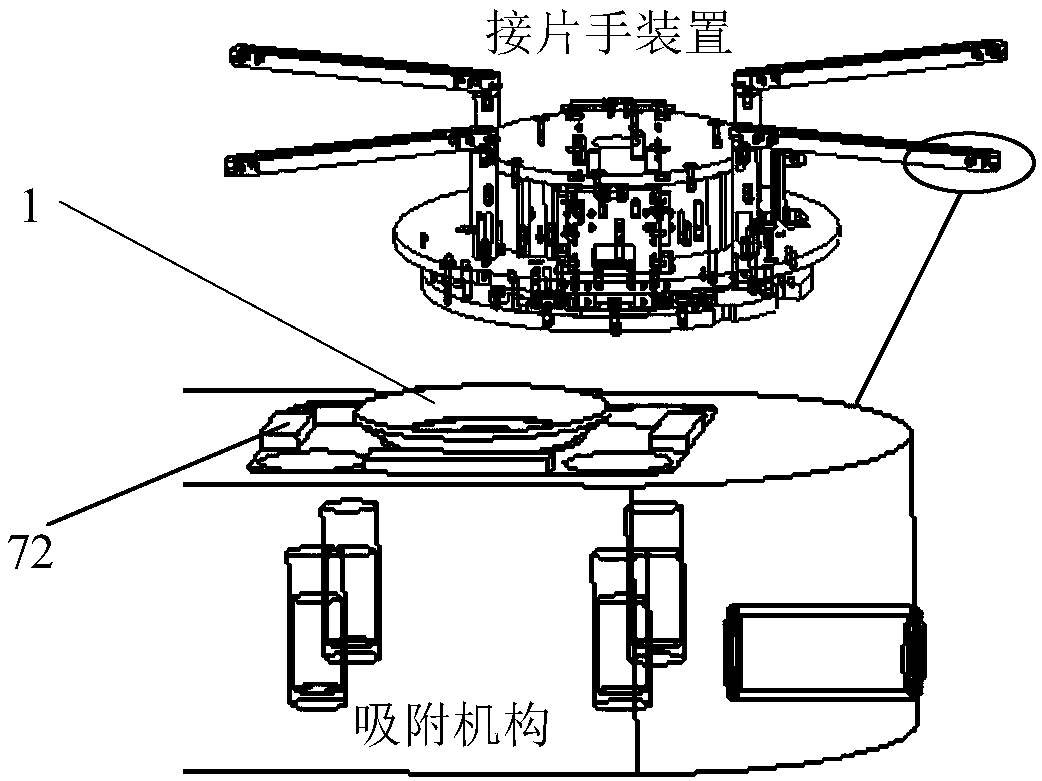

Substrate adsorption mechanism, substrate transferring device and method

A technology of adsorption mechanism and substrate, which is applied in the field of substrate adsorption mechanism and substrate transfer device, can solve the problems of insufficient substrate adsorption effect, reduced substrate deformation, lack of flexibility, etc., to reduce the probability of vacuum leakage, reduce Effect of warpage deformation and improvement of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

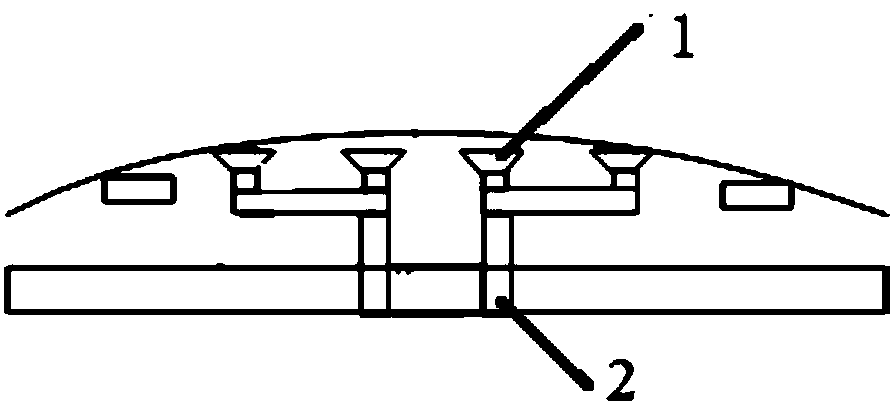

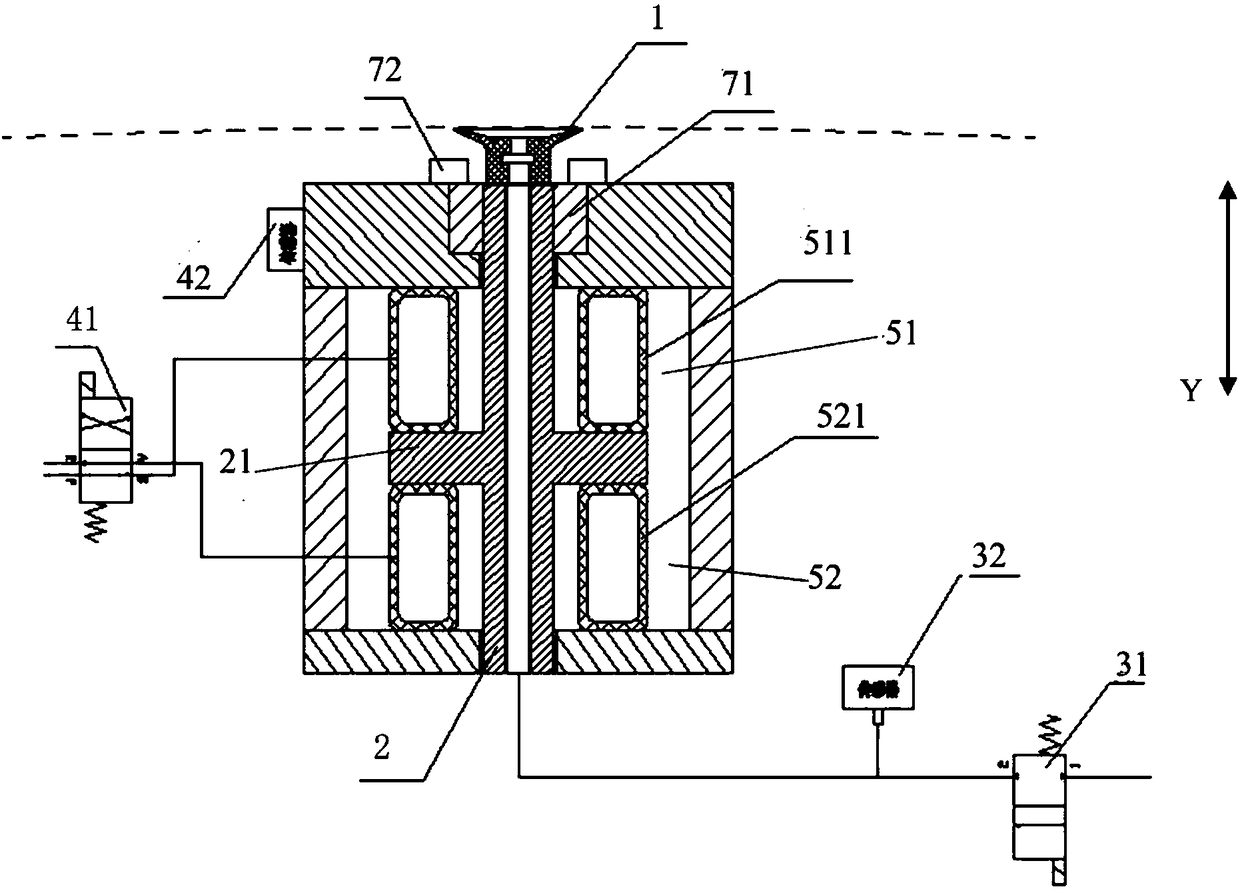

[0041] This embodiment proposes a substrate adsorption mechanism, which includes a support frame 7, a suction nozzle 1, an adsorption column 2, a first control loop and a second control loop. Specifically, such as image 3 or Figure 4As shown, the support frame 7 is a cylindrical support frame, and the present invention does not impose any restrictions on the shape and structure of the support frame 7; the support frame 7 is provided with a linear motion bearing 71, and the linear motion bearing 71 is sleeved on the adsorption column 2, Guide for the movement of the adsorption column 2. A limit stop 72 is also provided on the support frame 7, and the limit stop 72 is located under the suction nozzle 1, and is used for mechanical limit during the recovery process of the warping deformation of the substrate. Suction nozzle 1 is installed on the top of adsorption column 2, is used for adsorption substrate, and suction nozzle 1 structure can be cylinder, also can be cone, and t...

no. 2 example

[0057] This embodiment is a modification of the first embodiment.

[0058] Such as Figure 9 or Figure 10 As shown, different from the substrate adsorption mechanism in the first embodiment, the first flexible member in the first chamber 51 in this embodiment is the first spring 512, and the second flexible member in the second chamber 52 is the first spring 512. The second spring 522 plays the role of buffering and damping the base when the base is handed over. The present invention does not impose any limitation on the material, quantity and shape of the first spring 512 and the second spring 522 . The first spring 512 is arranged around the adsorption column 2, the top of the first spring 512 is connected to the support frame 7, and the bottom end is connected to the shoulder 21 of the adsorption column; the second spring 522 is arranged around the adsorption column 2, and its top is connected to the shoulder 21 of the adsorption column connect.

[0059] The adsorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com