A kind of electrolyte solution, negative pole and a kind of lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of electrolyte and negative electrode, can solve the problems of reduced battery cycle performance and increased transmission rate of battery polarization, etc., and achieve the effect of excellent lithium conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

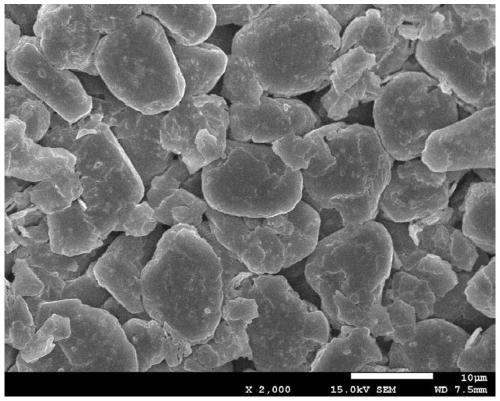

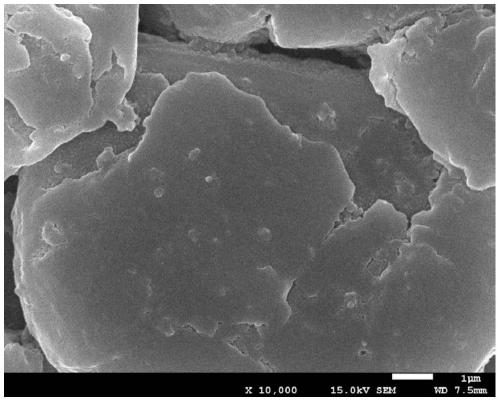

Image

Examples

preparation example Construction

[0056] Since the preparation process of the negative electrode sheet, the positive electrode sheet, and the separator are well-known technologies in the art, and the assembly of the battery is also a well-known technology in the art, details will not be repeated here.

[0057] In a lithium-ion battery, the additives in the electrolyte can be completely consumed in the end and form a dense film with excellent lithium-conducting properties on the surface of the negative electrode, and there may also be some residues in the electrolyte.

[0058] The preparation of the battery in the present invention can be prepared by encapsulating the conventional positive electrode, negative electrode and the electrolyte solution provided by this application in the field, and the additives described in this application added to the electrolyte solution are first and / or During the secondary charge and discharge process, an electrochemical reaction can occur, and a dense film with excellent lithi...

Embodiment 1

[0063] Step 1, preparation of negative electrode material:

[0064] 1. Weigh 200ml of N-methylpyrrolidone (NMP) in a 500ml beaker and stir;

[0065] 2. Add 100g poly(styrene sulfonic acid) to the above beaker and stir for 30min;

[0066] 3. Weigh 50g of lithium carbonate and slowly add to the above beaker, stir for 1h;

[0067] 4. Add 50g of graphite and continue to stir for 2h;

[0068] 5. Add a sufficient amount of hydrochloric acid dropwise until there are no more bubbles in the beaker;

[0069] 6. Stop stirring, filter with suction, wash with deionized water, and then dry to obtain graphite whose surface is coated with poly(styrenesulfonic acid) lithium salt, wherein R1-R4 are F elements;

[0070] 7. Disperse the above-mentioned graphite coated with poly(styrene sulfonate) lithium salt on the surface and conductive carbon black, styrene-butadiene rubber, and carboxymethyl cellulose in a deionized Negative electrode slurry is obtained in water;

[0071] 8. Coat the eve...

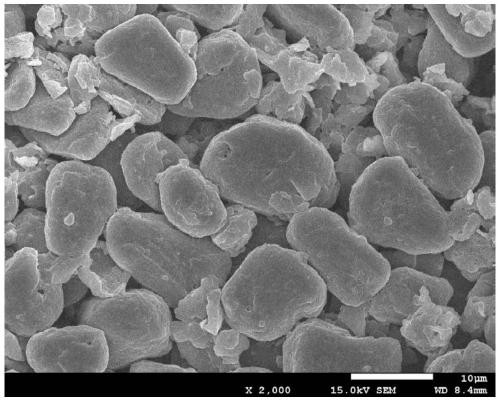

Embodiment 2

[0077] Adopt the same steps as in Example 1 to prepare the negative electrode material, the difference is: the poly(styrene sulfonate) lithium salt used in step 1, wherein R1 to R4 are H elements;

[0078] Electrolyte and battery are prepared in the same steps as in Example 1, the difference is: 1% by weight of cyclic tris(dimethylsiloxane) trisulfate in step 2; 10% by weight of LiPF 6 The obtained non-aqueous organic electrolyte is denoted as C2 and battery S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com