Cyperus esculentus harvester

A technology for oil bean and harvester, applied in the direction of excavator harvester, harvester, excavator, etc., can solve the problems of high production cost, high labor intensity, low recovery rate, etc., and achieve high production efficiency and strong labor. low-amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

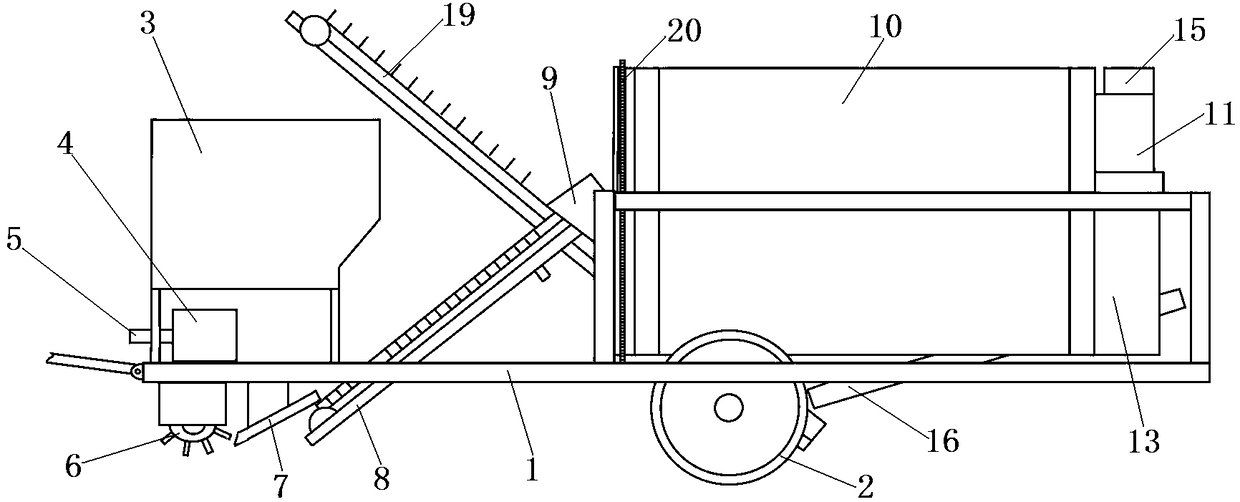

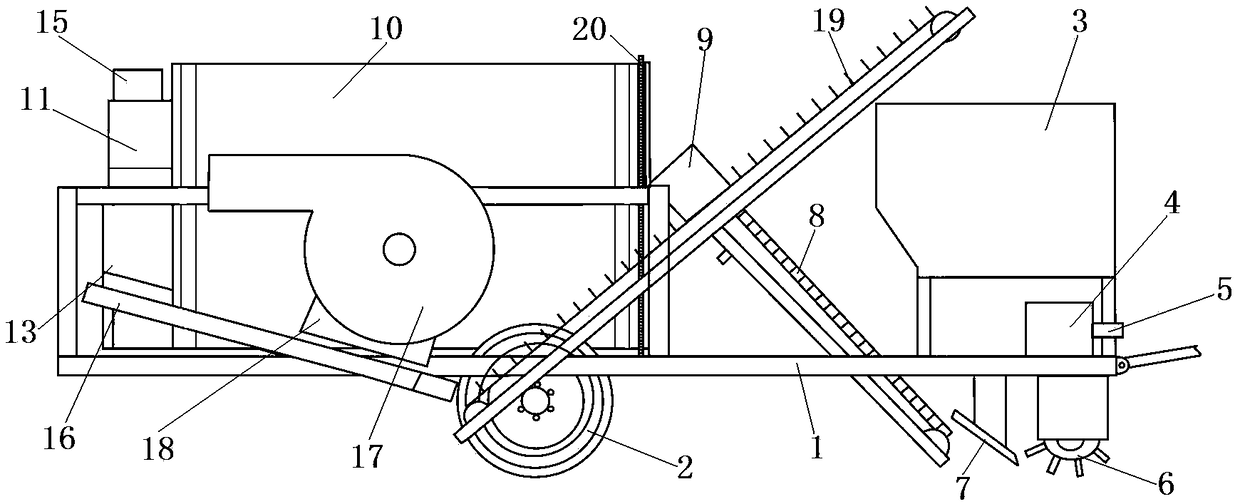

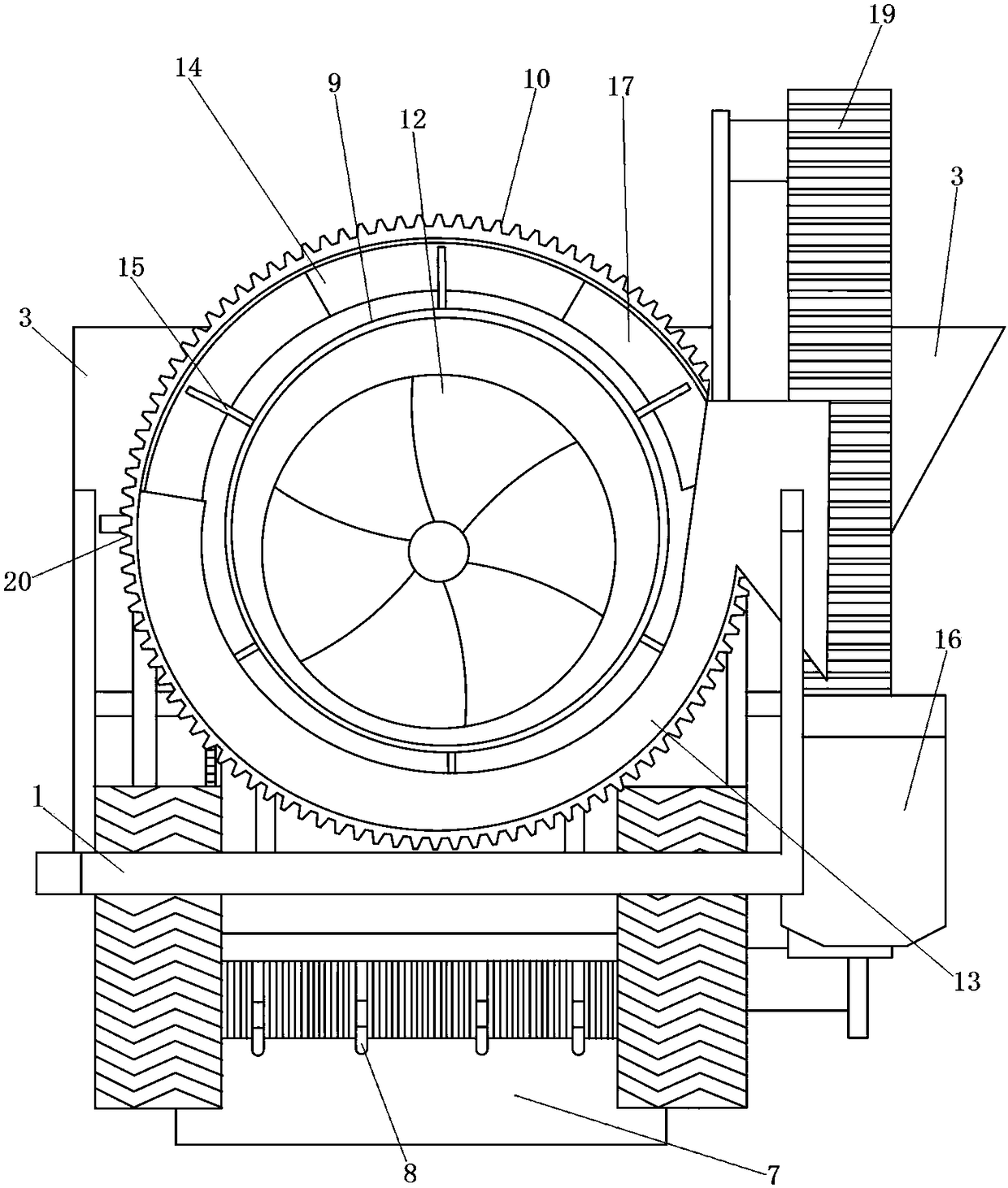

[0025] refer to figure 1 , figure 2 , image 3 , the oily bean harvester of the present invention comprises a frame 1, a frame walking wheel 2, an oily bean collection bucket 3, a transmission box 4, a rotary tiller 6, a shovel plate 7, a lifting wire mesh belt 8, a cylinder Shaped outer screen cylinder 10, cylindrical inner screen cylinder 11, helical blade pusher 12, outer screen cylinder discharge receiving tank 13, plane vibrating screen 16, miscellaneous suction fan 17, oil sand bean bucket conveyor belt 19, transmission box 4 to the transmission mechanism of each moving part. The oily bean storage bucket 3 is installed on the front end of the frame 1, and the transmission box 4 is fixed under the oily soybean storage bucket 3 at the front end of the frame 1, and the transmission box 4 extends out and is connected with the power output shaft of the tractor. The power input shaft 5 and the output shaft stretched out through the gear transmission in the case. Rotary ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com