Straw pelletizing grain combine harvester

A technology for combine harvesters and granular materials, applied to harvesters, mold extrusion granulation, crop processors, etc., to achieve simple structure, convenient use, and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

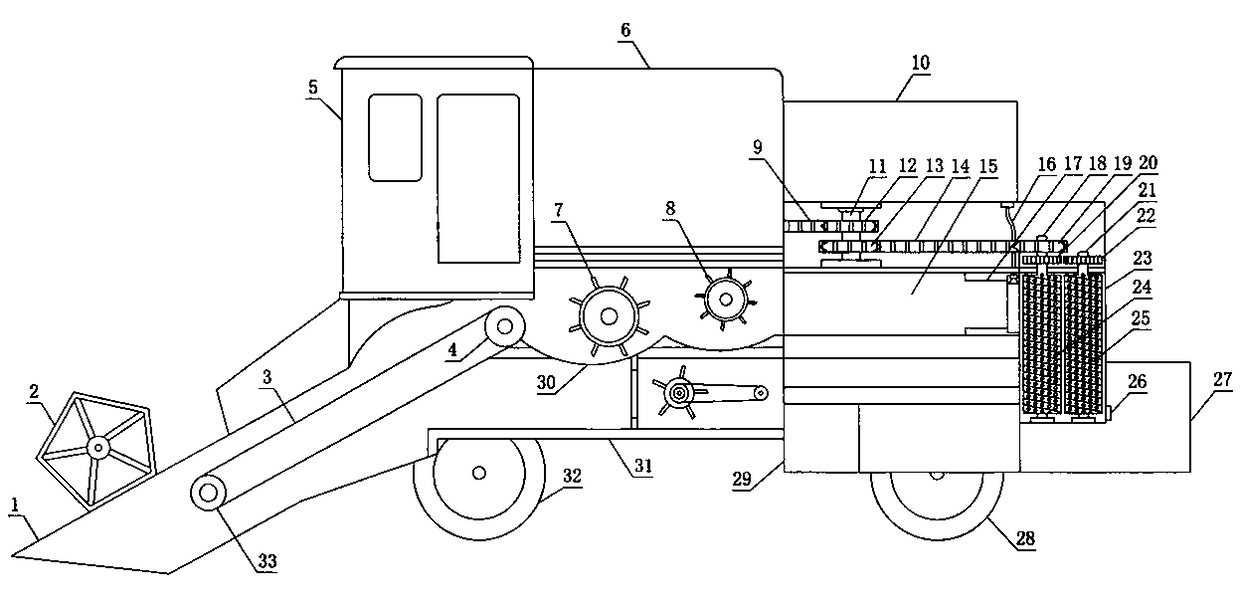

[0010] figure 1 The front end of frame 31 shown in is provided with harvesting platform 1, and the front upper end of harvesting platform is provided with reel 2, and the rear upper side of harvesting platform is provided with feeding conveyer belt driving wheel 4, and the front lower end of harvesting platform is provided with feeder. The conveyor belt follower wheel 33, the conveyor belt drive wheel and the follower wheel are equipped with a feeding conveyor belt 3, the rear side of the feeding conveyor belt is provided with a threshing drum 7, the lower end of the threshing drum is provided with a screen 30, and the rear side of the threshing drum is provided with straw Crushing drum 8, the straw crushing drum is provided with a cutting knife, the rear side of the straw crushing drum is provided with a straw discharge channel 15, the rear side of the straw discharge channel is provided with a straw collection pipe 17, and the rear side of the straw collection pipe is provide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap