Frameless combined permanent magnet synchronous linear motor direct-driving type jaw crusher

A technology of permanent magnet synchronous linear and jaw crushers, applied in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of difficult ratio transmission, easy contamination of oil, poor reliability, etc., and achieve high control accuracy, Simplify the driving method and structure, and the effect of fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

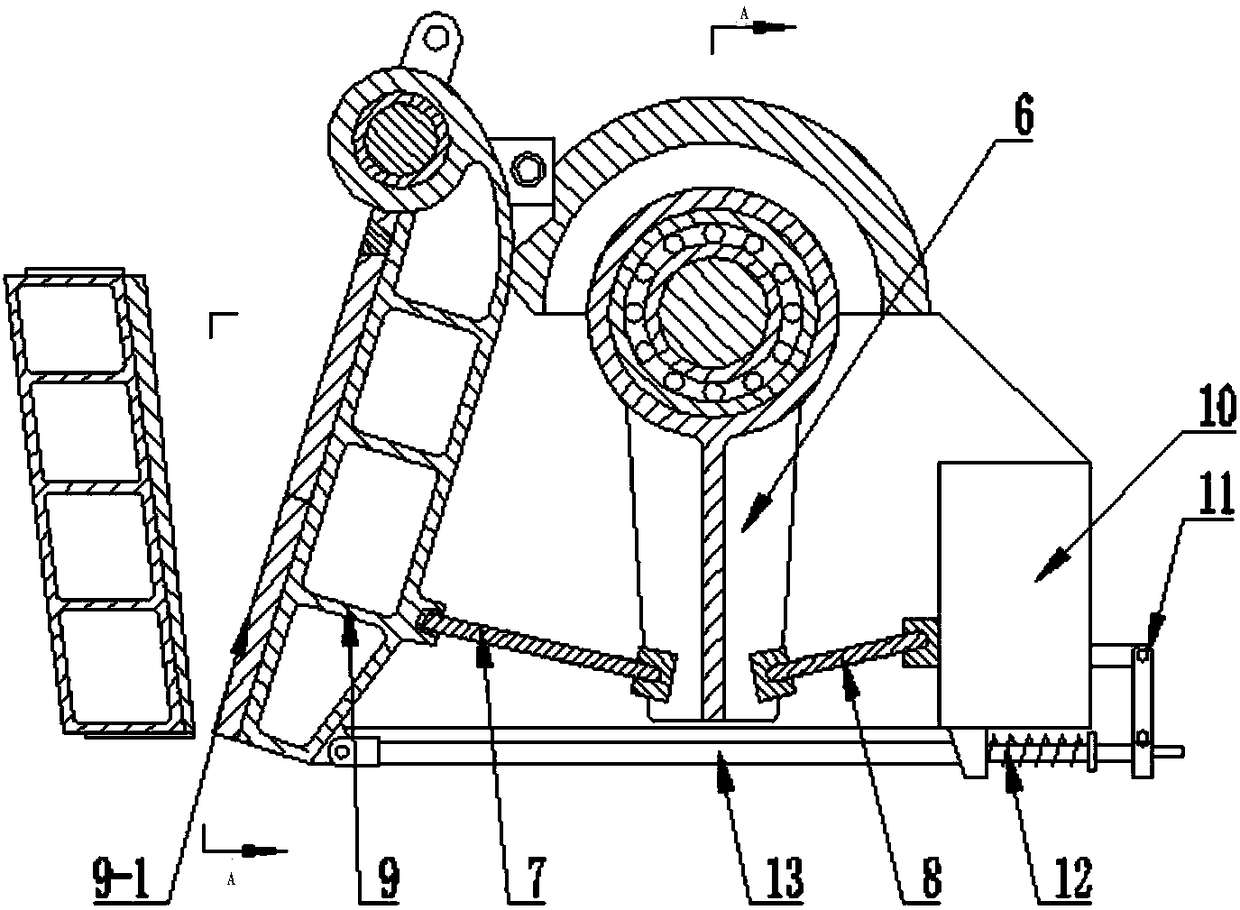

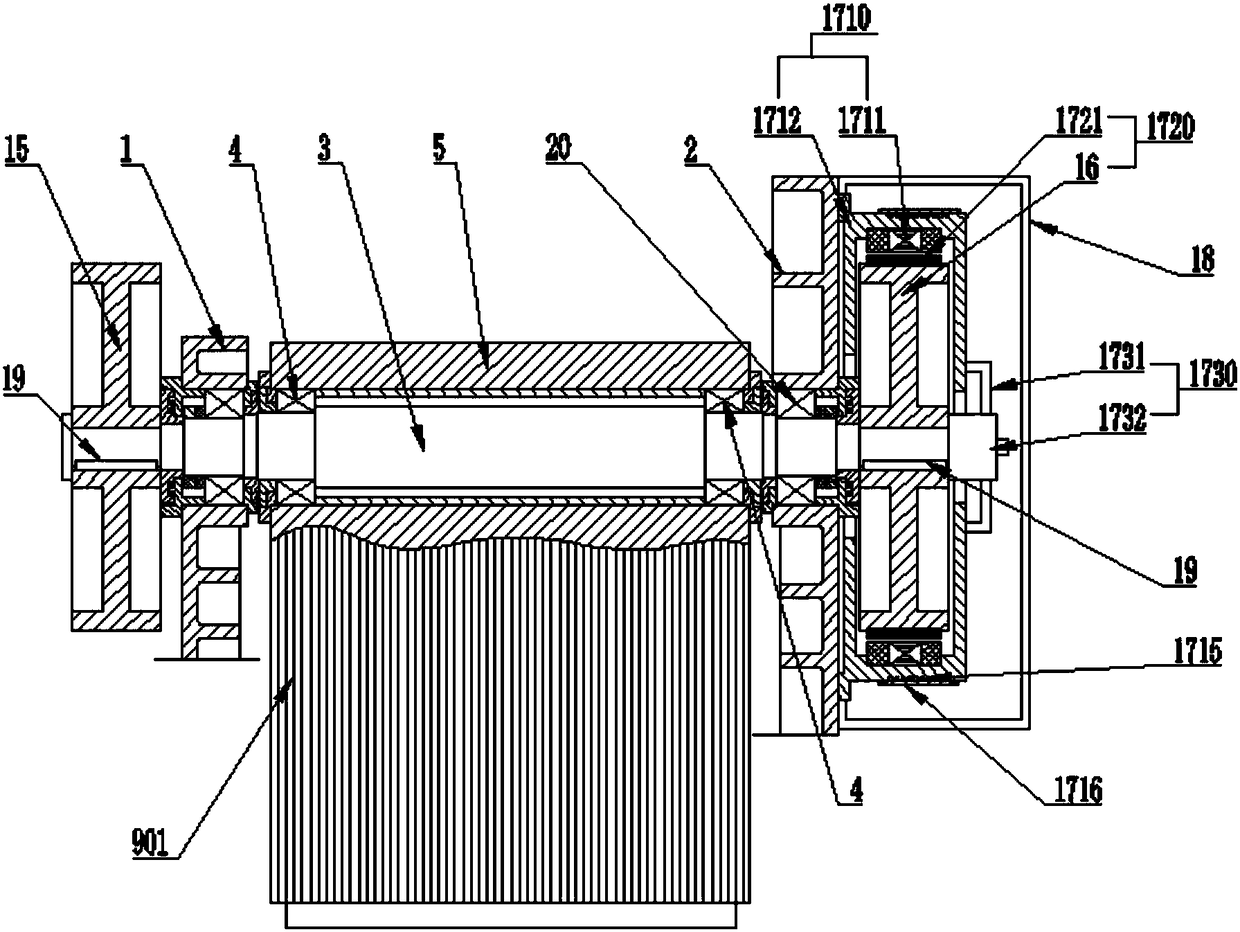

[0034] Such as Figure 1-5As shown, a jaw crusher directly driven by a frameless combined permanent magnet synchronous linear motor includes a first frame 1 and a second frame 2, and between the first frame 1 and the second frame 2 A rotating shaft 3 is provided, and an eccentric bushing 5 is connected to the rotating shaft 3 through a support bearing 4. A connecting rod 6 is arranged on the eccentric bushing 5, and a front toggle plate 7 and a rear toggle plate 7 are arranged on the connecting rod 6. A toggle plate 8, the rear toggle plate 8 is connected with a movable jaw support 9, and the movable jaw support 9 is provided with a movable jaw plate 901; the front toggle plate 7 is connected with an adjustment mechanism 10, and the adjustment mechanism 10 passes A link mechanism 11 is fixedly connected to one end of a pull rod 13 which is equipped with a spring 12, and the other end of the pull rod 13 is movably connected to the lower part of the movable jaw support 9, and th...

Embodiment 2

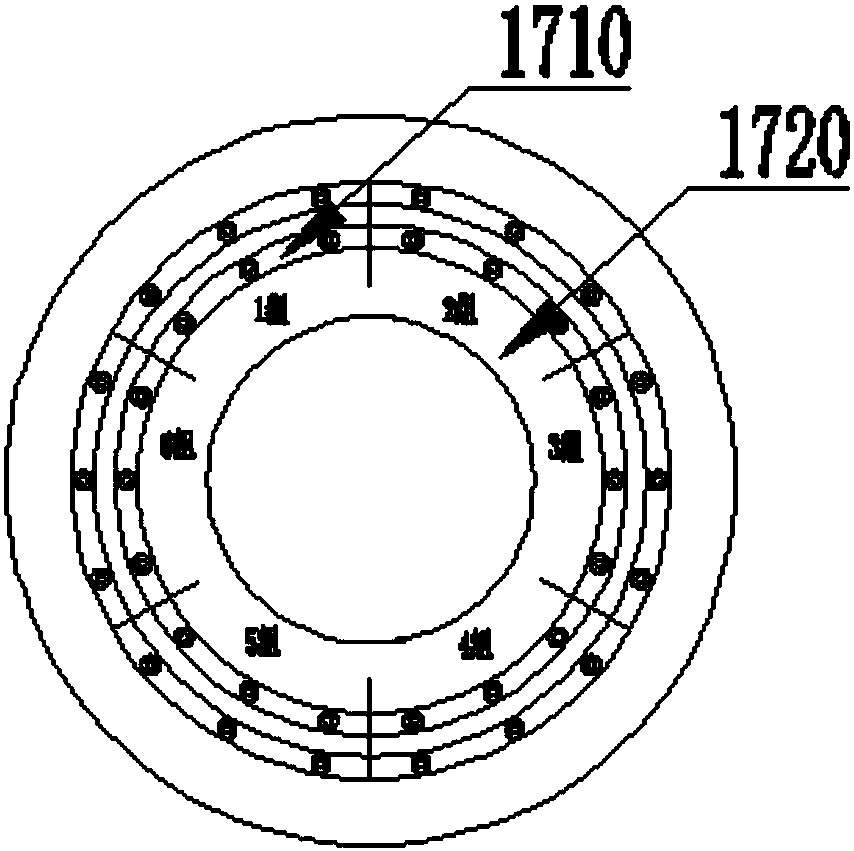

[0046] Such as Figure 6-8 As shown, a jaw crusher directly driven by a frameless combined permanent magnet synchronous linear motor, this embodiment is similar in structure and principle to Embodiment 1, the difference between this embodiment and Embodiment 1 is that the stator assembly 1710 includes a stator unit 1713 with a fan-shaped disk structure, and the stator unit 1713 with a fan-shaped disk structure is an annular disk structure formed integrally. The stator units 1713 of the fan-shaped disk structure are evenly arranged on the circumference of the disk-shaped stator base 1714 , and the disk-shaped stator base 1714 is fixedly installed on the second frame 2 .

[0047] The stator assembly 1710 also includes a disc-shaped stator base 1714, the disc-shaped stator base 1714 is in a ring structure, and the stator units 1713 of the fixed-sector disc-shaped structure are evenly arranged on the disc-shaped stator base in the circumferential direction. 1714 , the disc-shaped...

Embodiment 3

[0052] Such as Figure 9 As shown, a jaw crusher directly driven by a frameless combined permanent magnet synchronous linear motor, the structure and principle of this embodiment are similar to those of embodiment 1 or embodiment 2, and this embodiment is similar to that of embodiment 1 or embodiment 2 The difference is that the frameless combined permanent magnet synchronous linear motor described in this embodiment is the combination of the frameless combined permanent magnet synchronous arc linear motor 23 and the frameless combined permanent magnet synchronous disc linear motor 24 Combination, arc stator base and disc stator base are integrated.

[0053] After the power is turned on, the stator unit 1711 of the fan-shaped arc-shaped structure provides a radially rotating magnetic field for the arc-shaped magnetic steel substrate 1721, and the stator unit 1713 of the fan-shaped disc-shaped structure is the disk-shaped magnetic steel substrate 1722 An axially rotating magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com