Odor control and deodorization system of refuse landfill

A landfill and garbage technology, which is applied in the field of sanitation waste treatment, can solve problems such as the difficulty in meeting the emission standards and specifications of odorous pollutants, the difficulty in meeting the environmental quality requirements of surrounding residents, and affecting the overall planning and investment environment of the surrounding area. Achieve the effect of good odor control and deodorization effect, excellent odor control performance and good deodorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

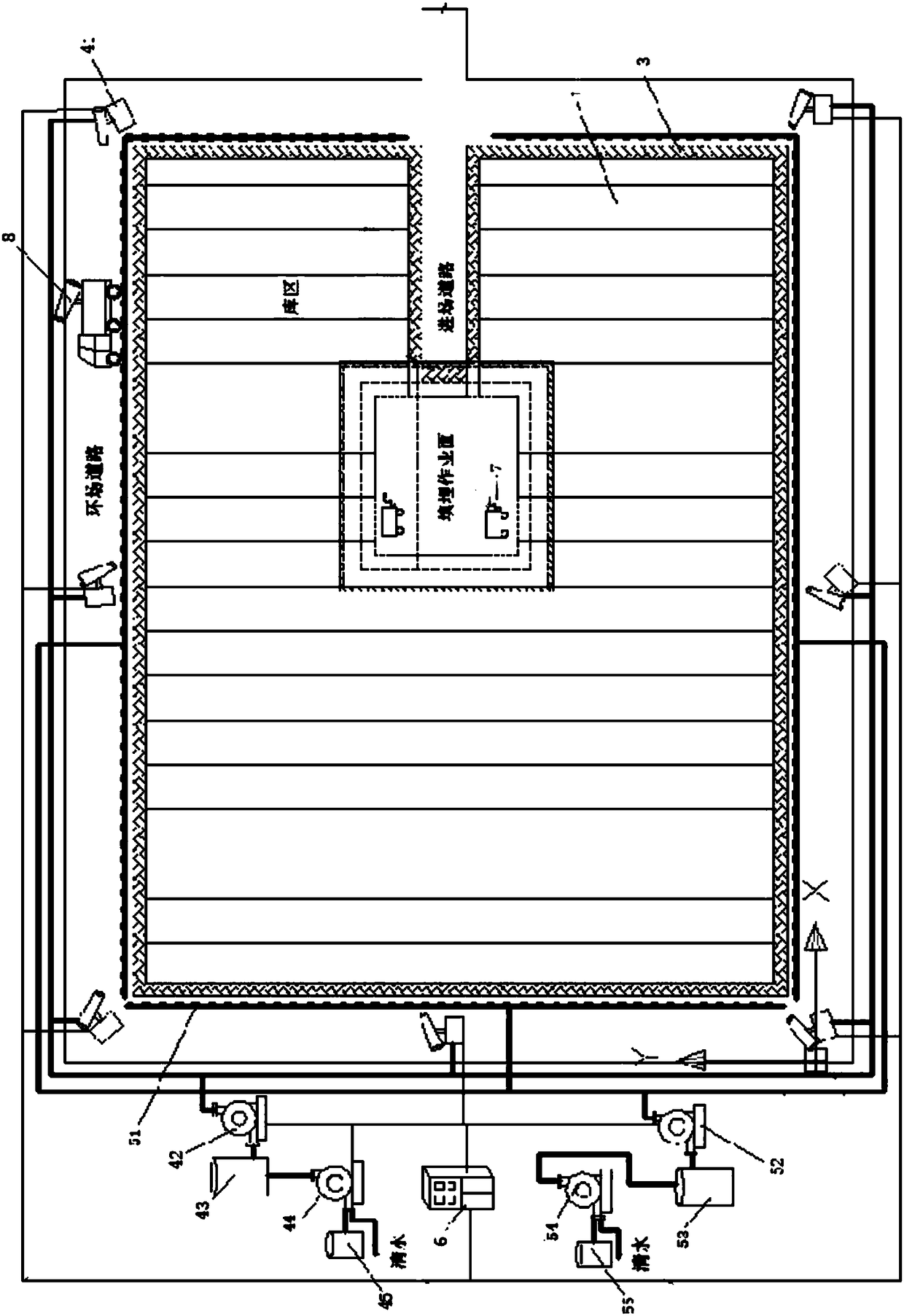

[0030] refer to figure 1 As shown, the present invention provides an odor control and deodorization system for a landfill site, including: a film-covered airtight odor control unit 1 in the reservoir area, an anti-seepage film airtight odor control unit 2 on the landfill operation surface, an annular field and a partition film anchoring airtight unit Odor control unit 3; the storage area film-covered airtight odor control unit 1 is used for odor control of garbage piles in the garbage storage area, and the storage area film-covered airtight odor control unit 1 is close to or surrounds the landfill operation surface. The odor control unit 2 is set, and the anti-seepage film airtight odor control unit 2 of the landfill operation surface is used for the odor control of the garbage landfill operation surface; Periphery of smelly unit 1.

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com