Intelligent adjusting system for height of multi-shaft heavy-duty cross-country chassis

A chassis height and intelligent adjustment technology, which is applied in the direction of elastic suspension, suspension, transportation and packaging, etc., can solve the problems of affecting vehicle maneuverability, many adjustment restrictions, and low degree of intelligence, so as to achieve good driving performance, The effect of improving the rapid passing ability and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

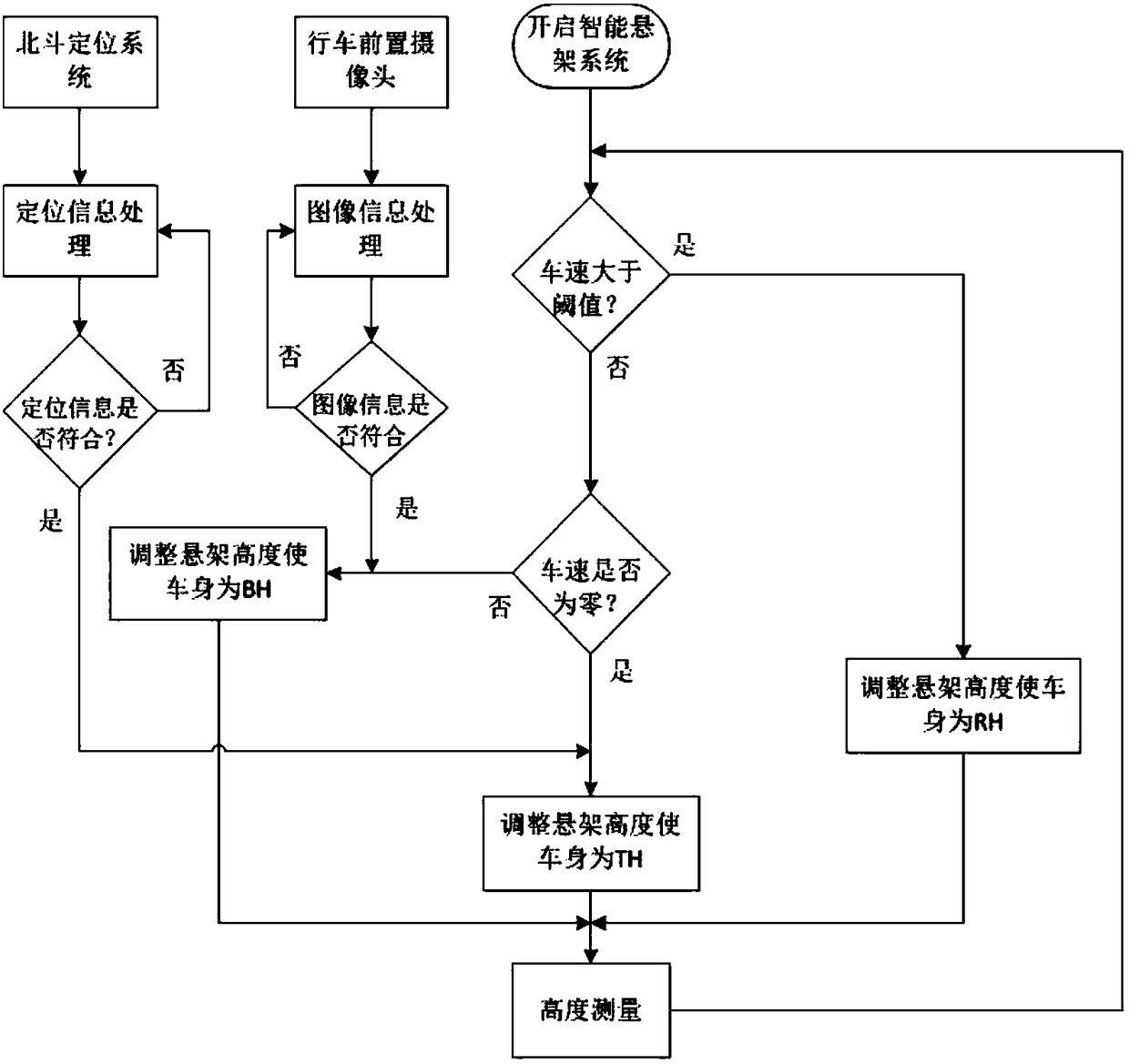

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

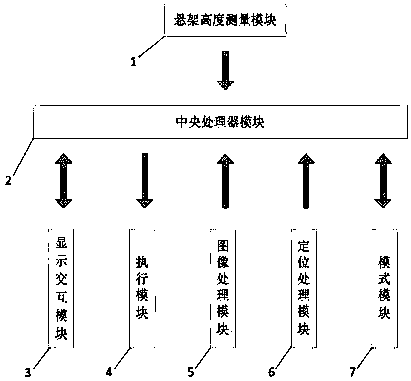

[0020] Such as figure 1 As shown, a multi-axis heavy-duty off-road chassis height intelligent adjustment system includes the following modules: suspension height measurement module 1, central processing unit module 2, display interaction module 3, execution module 4, image processing module 5, positioning processing module 6, Mode module 7, each module consists of the following parts:

[0021] 1. Suspension height measurement module 1 includes: four angle sensors, four sensor brackets, four sensor spacers and four pull rods, such as image 3 The sensor bracket is fixed on the longitudinal beam of the frame, the sensor gasket is fixed on the lower cross arm assembly, the angle sensor is installed on the sensor bracket, and the two ends of the tie rod are respectively connected to the angle sensor and the sensor gasket through the structure of the ball head;

[0022] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com