High-voltage battery discharge circuit and control method thereof

A discharge circuit, high-voltage battery technology, applied in battery/fuel cell control devices, control devices, circuit breaker testing, etc., can solve problems such as battery pack structural damage, loss of battery pack components, and risk of fire, and improve safety. performance and reliability, improve use efficiency, and facilitate subsequent investigations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

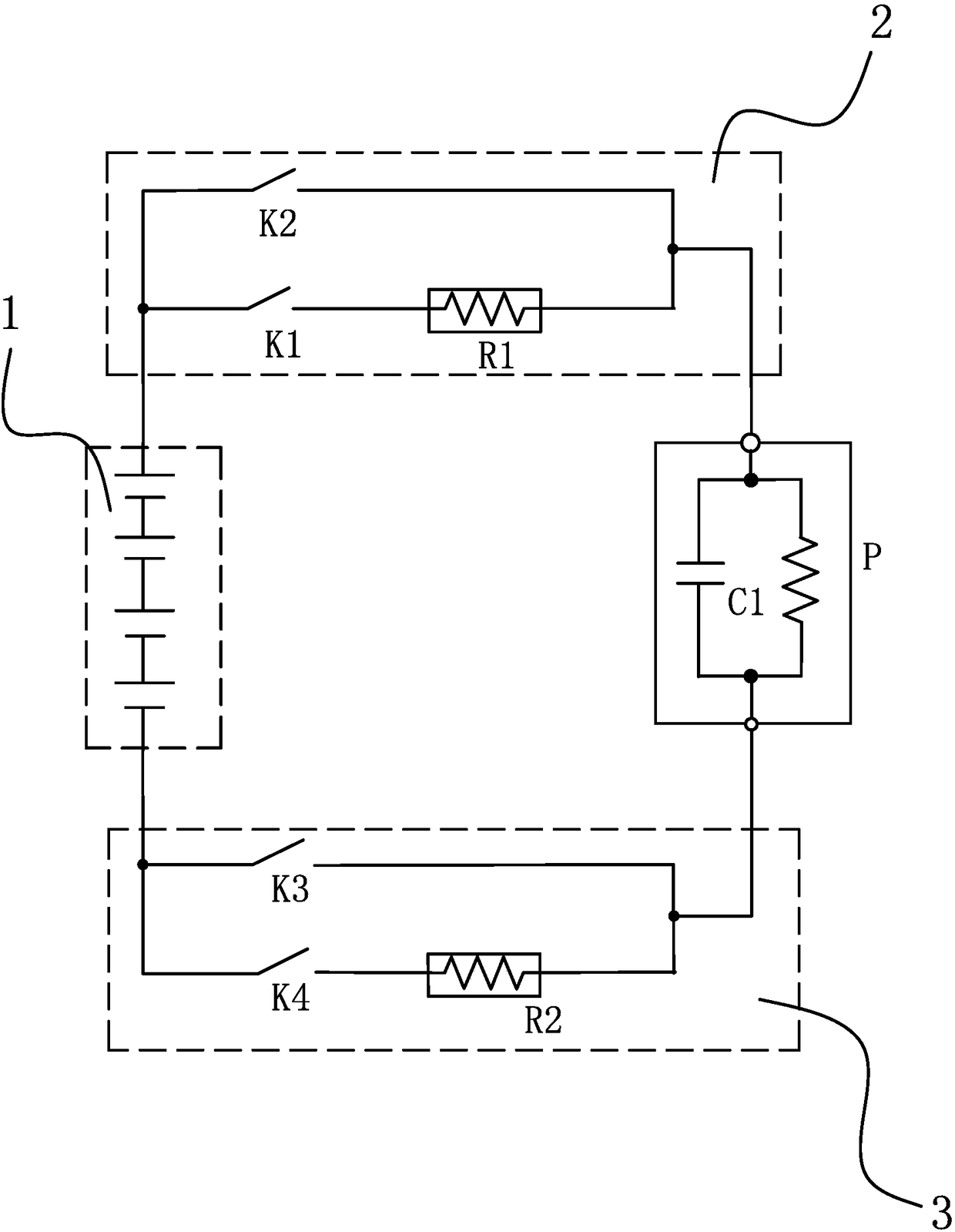

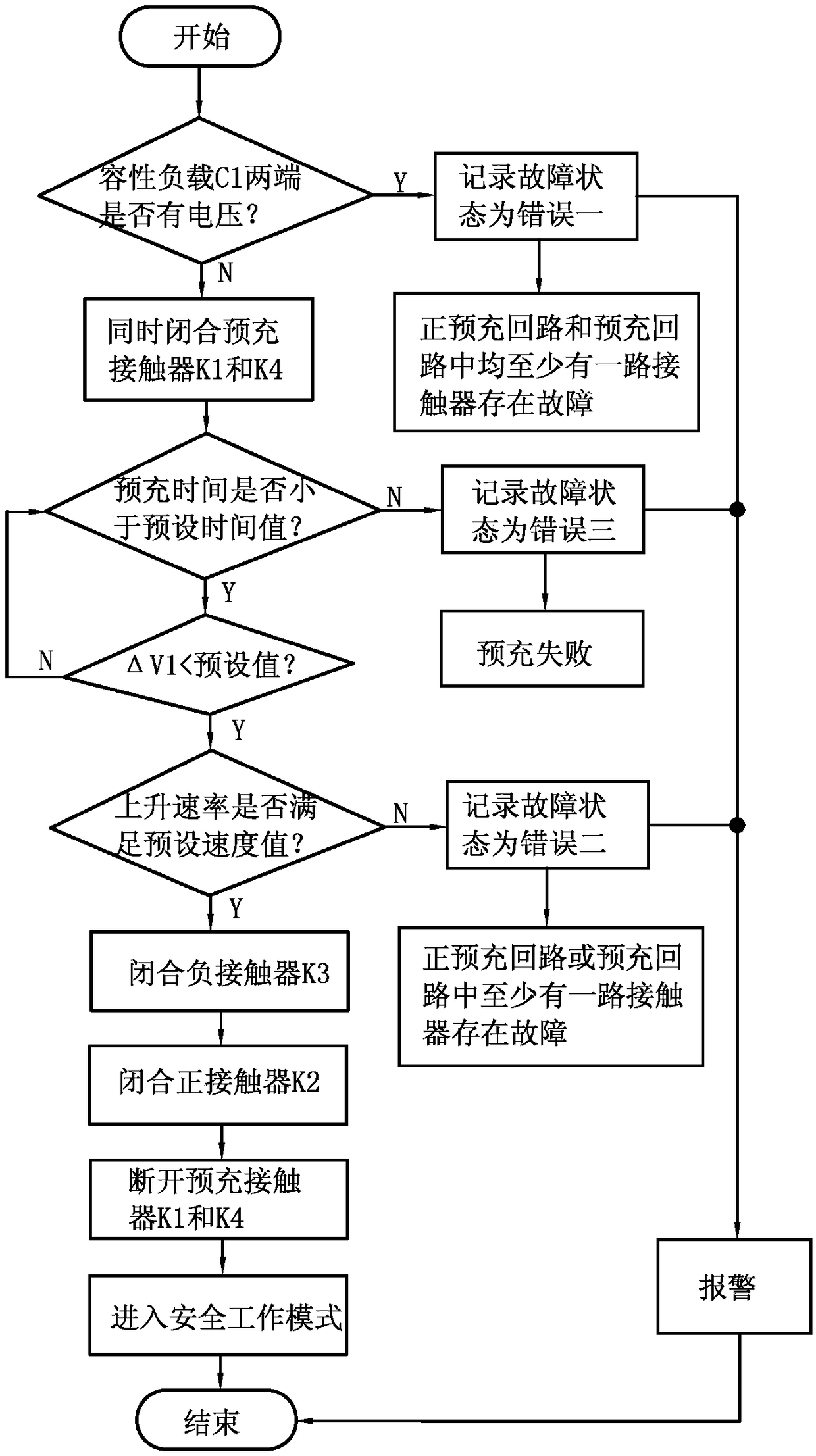

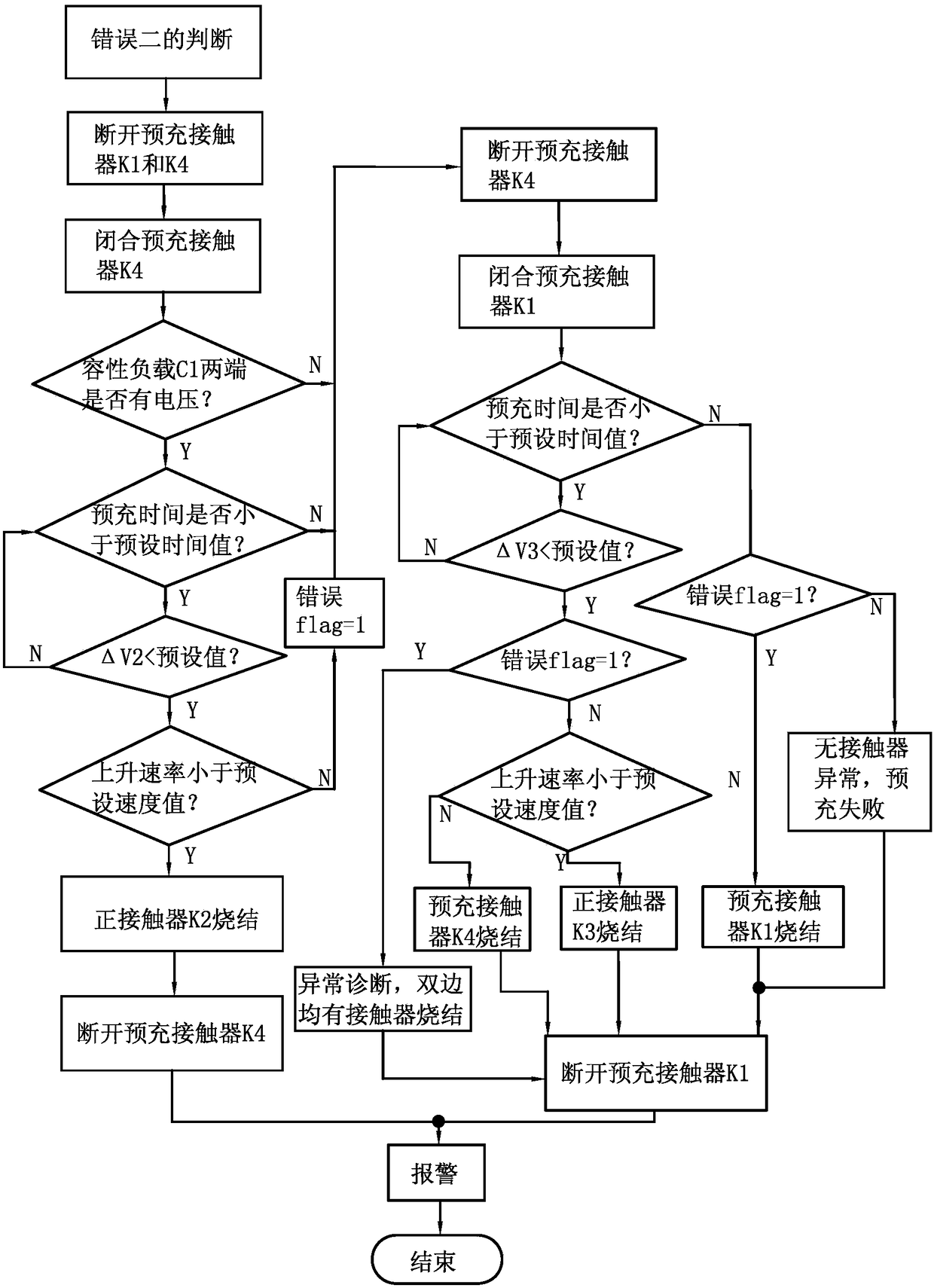

[0028] Such as figure 1 As shown, this high-voltage battery discharge circuit includes a battery pack 1, a positive pre-charging circuit 2, a negative pre-charging circuit 3, and a power element P with a capacitive load C1. The positive load C1 and the negative pre-charging circuit 3 are connected in series, the negative pre-charging circuit 3 is connected to the negative pole of the battery pack 1, the positive pre-charging circuit 2 includes the positive contactor K2, the pre-charging contactor K1 and the pre-charging resistor R1, the pre-charging contact Connector K1 and pre-charging resistance R1 are connected in series and connected in parallel at both ends of positive contactor K2. Negative pre-charging circuit 3 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com