Graphene asphalt concrete and preparation method thereof

A technology of olefinic asphalt and concrete, which is applied in the field of graphene asphalt concrete and its preparation, can solve the problems of prevention and control policies, imperfect laws and regulations, motor vehicle exhaust pollution, and insufficient governance, so as to prevent slippery and cracked road surfaces, The effect of protecting the environment and preventing garbage pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

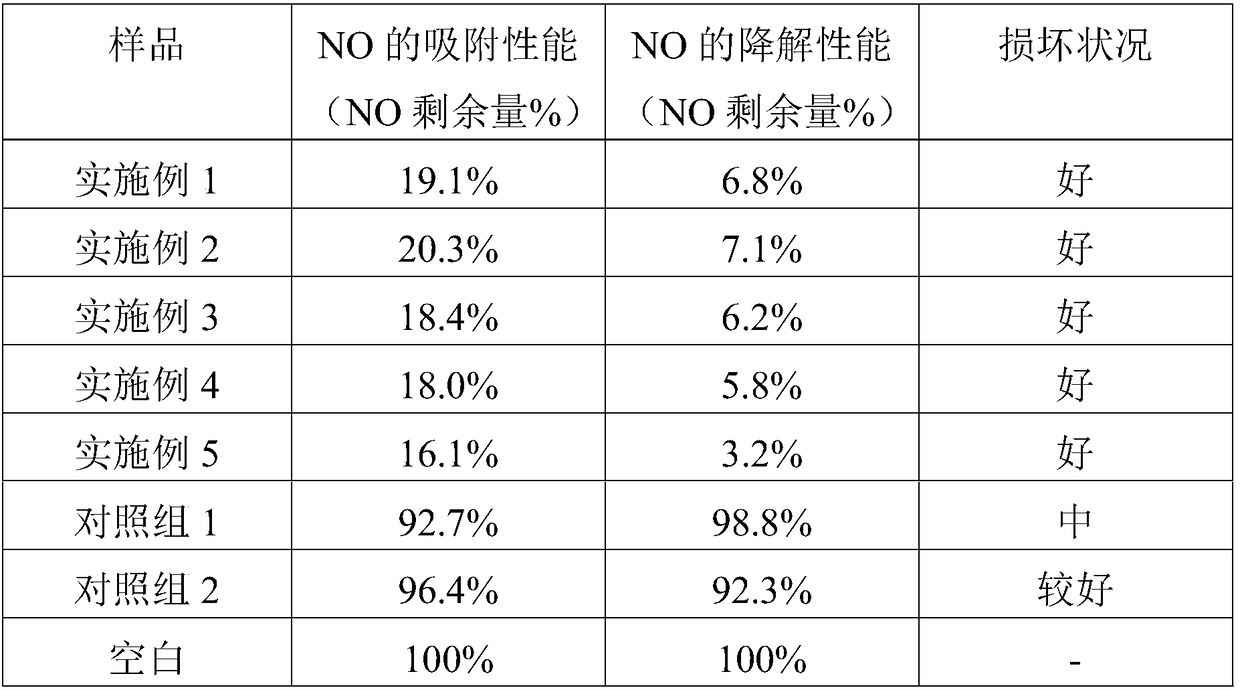

Examples

Embodiment 1

[0028] Prepare a kind of graphene asphalt concrete, the steps are as follows:

[0029] 1) Weigh parts by weight as required Raw materials: 300 parts of ordinary aggregate with a particle size of ≤12 mm, 40 parts of asphalt with a penetration of AH-70, 50 parts of slag powder, 10 parts of graphene oxide, titanium dioxide, and a length of 5 ~ 3 parts of 10mm carbon fiber.

[0030] 2) After heating the bitumen weighed in step 1) to 170±5°C to be in a liquid state, add the graphene oxide and titanium dioxide weighed in step 1), and stir at a stirring speed of 400r / min for 5min to obtain liquid graphene oxide Asphalt; at the same time, heat the aggregate weighed in step 1) to 175±5°C, and mix the liquid graphene oxide asphalt into the heated aggregate while it is hot, continue heating and mix evenly to obtain the mixture.

[0031] 3) When heating continuously to 170±5°C, add the slag powder and carbon fiber weighed in step 1) to the mixture prepared in step 2), stirring at a speed...

Embodiment 2

[0034] Prepare a kind of graphene asphalt concrete, the steps are as follows:

[0035] 1) Weigh parts by weight as required Raw materials: 500 parts of ordinary aggregate with a particle size of ≤12mm, 60 parts of asphalt with a penetration of AH-90, 80 parts of slag powder, 30 parts of graphene oxide, 30 parts of titanium dioxide, length It is 5 parts of 5-10mm carbon fiber.

[0036] 2) After heating the bitumen weighed in step 1) to 170±5°C to be in a liquid state, add the graphene oxide and titanium dioxide weighed in step 1) and stir for 15 minutes at a stirring speed of 500r / min to obtain a liquid graphene oxide pitch ; At the same time, heat the aggregate weighed in step 1) to 175±5°C, mix the liquid graphene oxide pitch into the heated aggregate while it is hot, continue heating and mix evenly to obtain the mixture.

[0037] 3) When heating continuously to 170±5°C, add the slag powder and carbon fiber weighed in step 1) to the mixture prepared in step 2), stirring at a...

Embodiment 3

[0040] Prepare a kind of graphene asphalt concrete, the steps are as follows:

[0041] 1) Weigh parts by weight as required Raw materials: 350 parts of ordinary aggregate with a particle size of ≤12 mm, 45 parts of asphalt with a penetration of AH-110, 60 parts of slag powder, 15 parts of graphene oxide, 15 parts of titanium dioxide, length 3.5 parts of 5-10mm carbon fiber;

[0042] 2) After heating the bitumen weighed in step 1) to 170±5°C to be in a liquid state, add the graphene oxide and titanium dioxide weighed in step 1), and stir at a stirring speed of 450r / min for 10min to obtain liquid graphene oxide Asphalt; at the same time, heat the aggregate weighed in step 1) to 175±5°C, mix the liquid graphene oxide asphalt into the heated aggregate while it is hot, continue heating and mix evenly to obtain the mixture;

[0043] 3) When continuously heating to 170±5°C, add the slag powder and carbon fiber weighed in step 1) into the mixture prepared in step 2), the stirring spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com