High-strength polyethylene and processing method thereof

A technology of high-strength polyethylene and processing method, applied in the field of polyethylene processing, can solve the problems of poor toughness, poor heat resistance, easy aging, etc., and achieve the effects of long service life, improved toughness, and not easy to aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

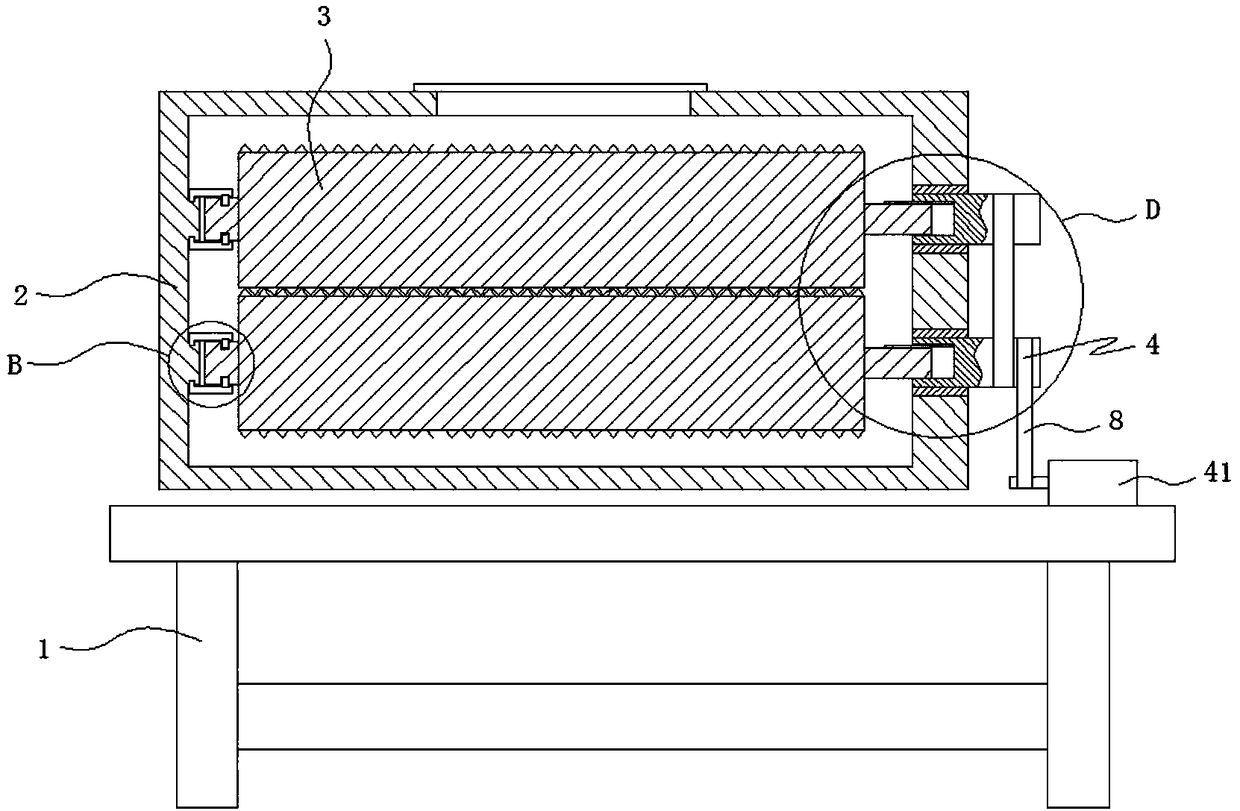

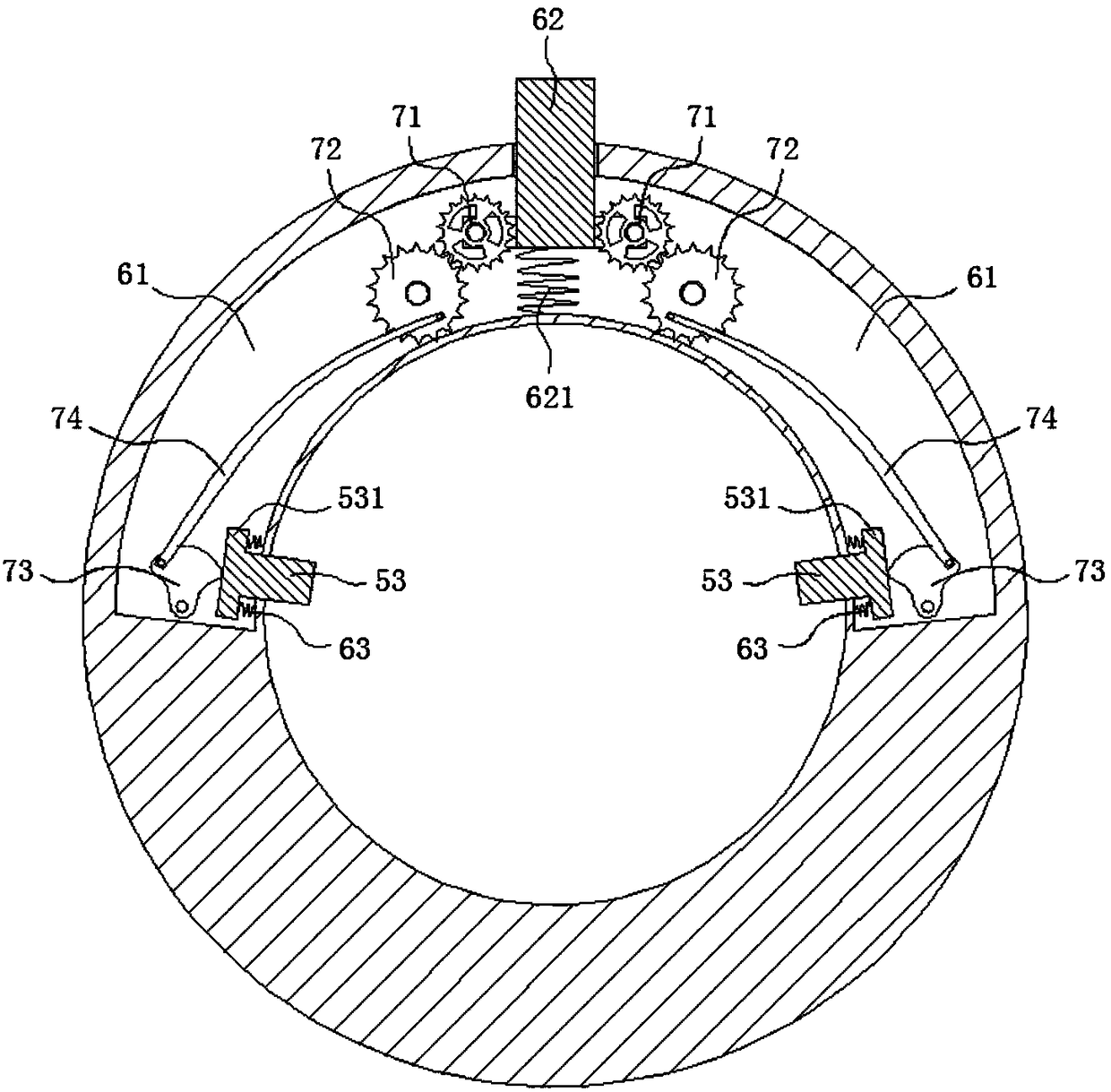

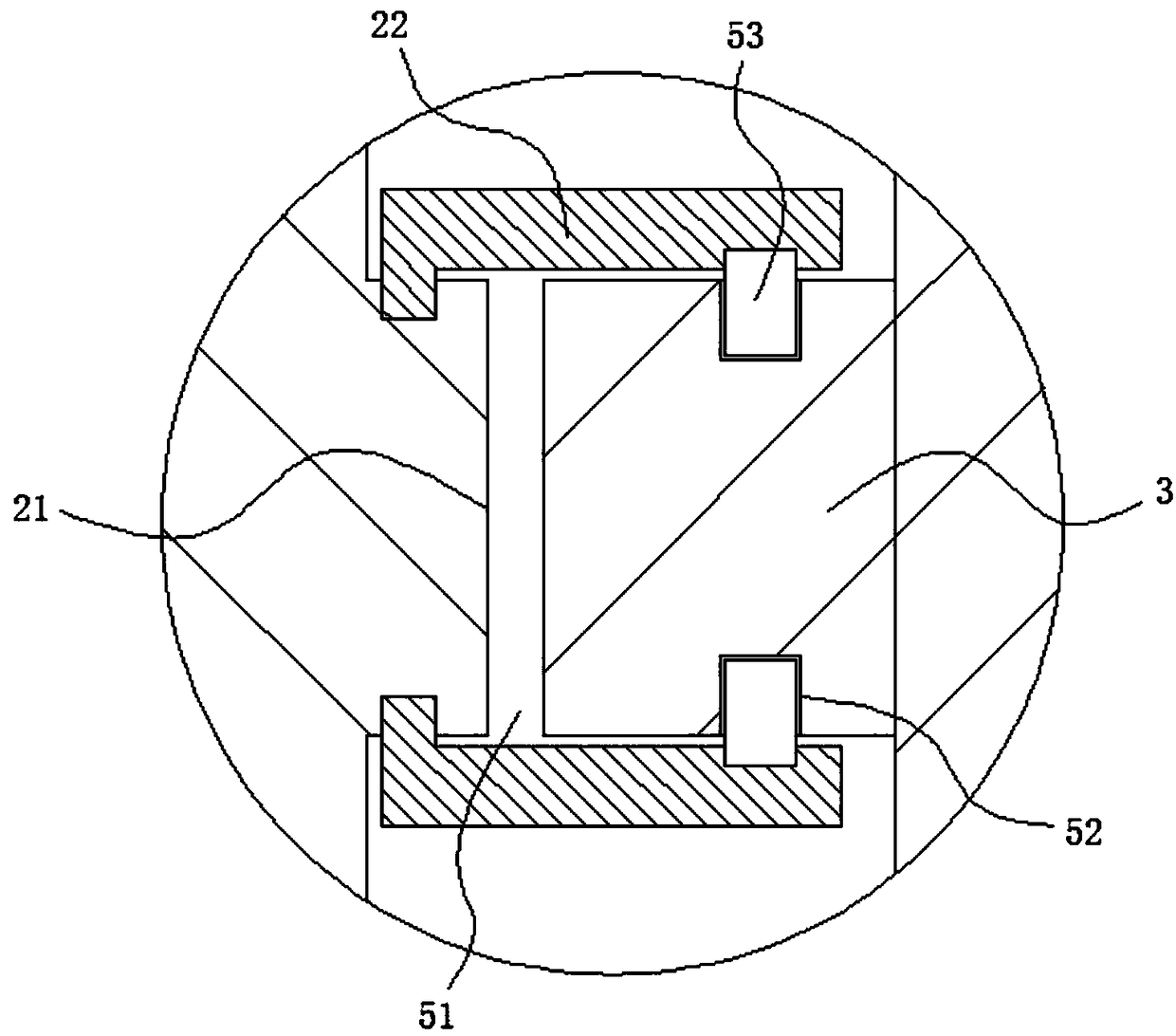

Image

Examples

Embodiment 1

[0025] A high-strength polyethylene, comprising the following components in parts by weight: 20 parts of high-pressure polyethylene, 5 parts of palygorskite powder, 3 parts of heat insulating agent, 2 parts of stabilizer, 1 part of carbon fiber, and 2 parts of glass fiber; The density of the high pressure polyethylene is 0.940g / cm 3 Both the heat insulating agent and the stabilizer are purchased directly on the market; the preparation method of the palygorskite powder is as follows: take the palygorskite, wash it with clear water and dry it, then expose it to the sun for 24 hours, and use a wheel mill to dry it after drying. The palygorskite is ground to obtain palygorskite powder after passing through 60 mesh.

[0026] A processing method for high-strength polyethylene, which is characterized in that it includes the following steps: (1) crushing polyethylene garbage through crushing equipment to obtain granular polyethylene, and the area of the granular polyethylene is cont...

Embodiment 2

[0037] A high-strength polyethylene, comprising the following components in parts by weight: 30 parts of high-pressure polyethylene, 8 parts of palygorskite powder, 5 parts of heat insulating agent, 3 parts of stabilizer, 3 parts of carbon fiber, and 3 parts of glass fiber; The density of the high pressure polyethylene is 0.960g / cm 3 Both the heat insulating agent and the stabilizer are purchased directly on the market; the preparation method of the palygorskite powder is as follows: take the palygorskite, wash it with clear water and dry it, then expose it to the sun for 72 hours, and use a wheel mill to dry it after drying. The palygorskite is ground and obtained, and the palygorskite powder is obtained after passing through 80 meshes; the wheel mill can be realized by the prior art.

[0038] A processing method for high-strength polyethylene, which is characterized in that it includes the following steps: (1) crushing polyethylene garbage through crushing equipment to obtai...

Embodiment 3

[0041] A high-strength polyethylene, comprising the following components in parts by weight: 30 parts of high-pressure polyethylene, 8 parts of palygorskite powder, 5 parts of heat insulating agent, 2 parts of stabilizer, 1 part of carbon fiber, and 3 parts of glass fiber; The density of the high pressure polyethylene is 0.945g / cm 3 Both the heat insulating agent and the stabilizer are purchased directly on the market; the preparation method of the palygorskite powder is as follows: take the palygorskite, wash it with clear water and dry it, then expose it to the sun for 60 hours, and use a wheel mill to dry it after drying. The palygorskite is ground to obtain palygorskite powder after passing through 80 mesh.

[0042] A processing method for high-strength polyethylene, which is characterized in that it includes the following steps: (1) crushing polyethylene garbage through crushing equipment to obtain granular polyethylene, and the area of the granular polyethylene is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com