Preparation method of liquid-state metal composite phase-change material

A technology of composite phase change materials and liquid metal, which is applied in the field of preparation of liquid metal composite phase change materials, can solve problems such as short circuit of electronic circuits, influence on normal operation of CPU, damage to CPU, etc., achieve efficient heat dissipation, satisfy heat dissipation, and prevent circuit short circuit problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0020] (1) Preparation of flexible carbon nanotube sponge carrier material:

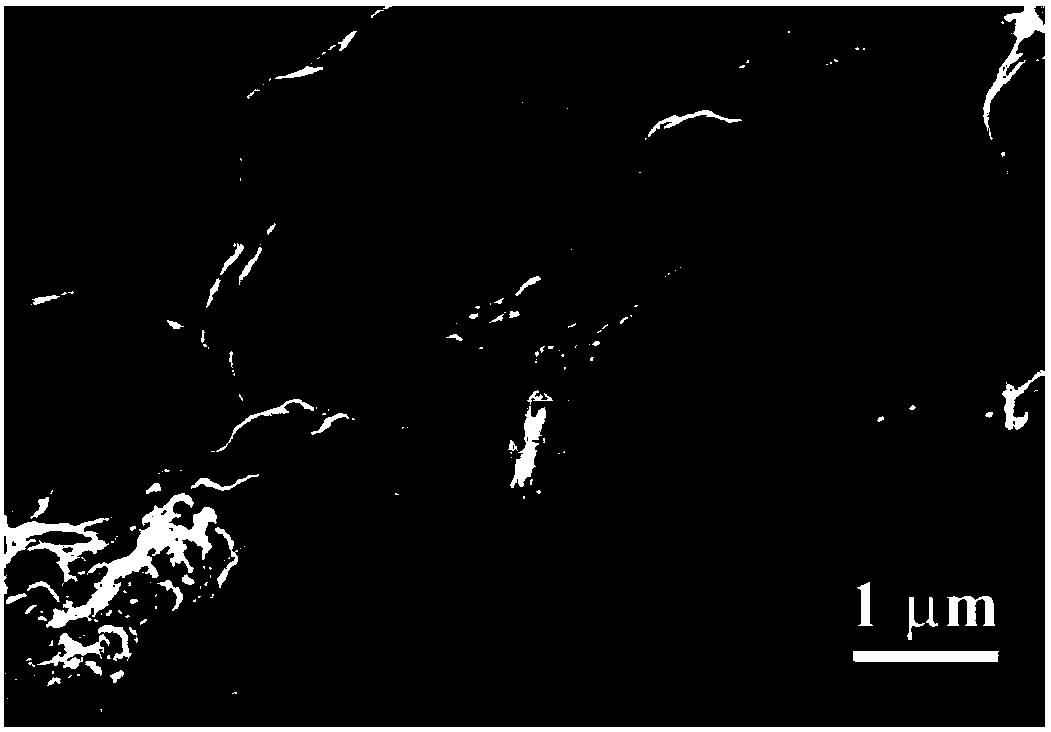

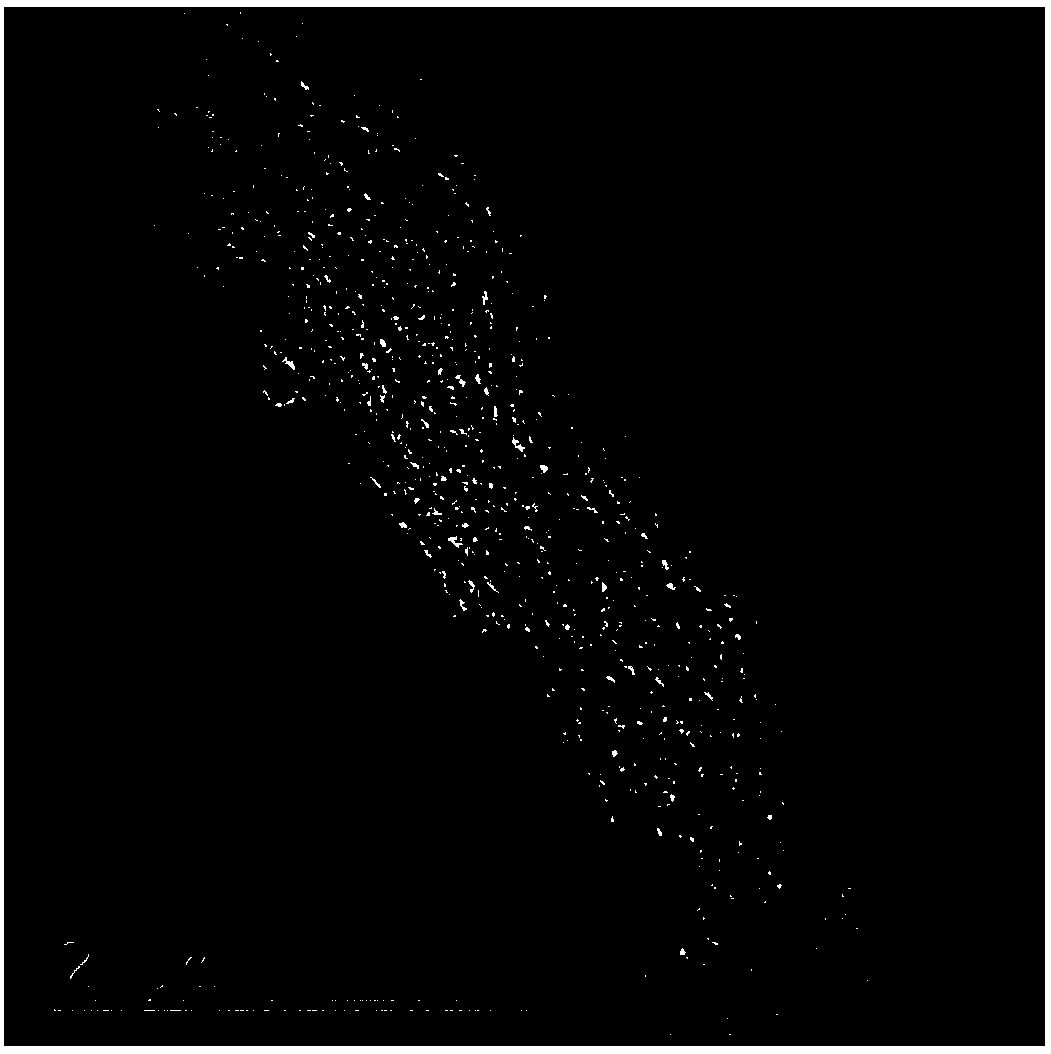

[0021] Mix 1g of polyvinylidene fluoride, 7g of sodium chloride and 0.2g of carbon nanotubes uniformly, then add them to a cylindrical mold, place in an oven at 200℃ for 4h, take out the product and immerse it in 90℃ hot water to completely dissolve the inside Sodium chloride, finally dried in a vacuum oven at 100°C for 24 hours to obtain a cylindrical flexible carbon nanotube sponge carrier material, where the flexibility is demonstrated as figure 1 As shown, SEM is like figure 2 As shown, TEM is like image 3 As shown, Raman Figure 4 Shown.

[0022] (2) Preparation of liquid metal composite phase change material:

[0023] The flexible carbon nanotube sponge carrier material prepared above was evacuated at 100° C. for 24 hours to completely open the internal pores. Then the vacuum treated carbon nanotube sponge carrier material and liquid metal Bi 45 Pb 23 Sn 8 Cd 5 In 19 At the same time, it is placed...

Embodiment example 2

[0025] (1) Preparation of flexible carbon nanotube sponge carrier material:

[0026] Mechanically mix 0.8g polyvinylidene fluoride, 5g sodium chloride and 0.3g carbon nanotubes, then add them to a square mold, place in a 220℃ oven for 2h, take out the product and immerse it in 80℃ hot water to completely dissolve it. The sodium chloride was finally dried in a vacuum oven at 120°C for 18 hours to obtain a square flexible carbon nanotube sponge carrier material.

[0027] (2) Preparation of liquid metal composite phase change material:

[0028] The flexible carbon nanotube sponge carrier material prepared above was evacuated at 100° C. for 18 hours to completely open the internal pores. Then the vacuum treated carbon nanotube sponge carrier material and liquid metal Bi 49 Pb 18 Sn 12 In 21 At the same time, it is placed in a vacuum flask and heated to 60℃ to melt it. In a vacuum environment, the liquid metal Bi 49 Pb 18 Sn 12 In 21 Adsorption is restricted in the pores, and then cooled...

Embodiment example 3

[0030] (1) Preparation of flexible carbon nanotube sponge carrier material:

[0031] Mix 0.6g polyvinylidene fluoride, 6g sodium chloride and 0.5g carbon nanotubes uniformly, then add them to a rectangular mold, place in an oven at 240℃ for 1h, take out the product and immerse it in 85℃ hot water for complete dissolution The sodium chloride inside was finally dried in a vacuum oven at 140°C for 20 hours to obtain a rectangular flexible carbon nanotube sponge carrier material.

[0032] (2) Preparation of liquid metal composite phase change material:

[0033] The flexible carbon nanotube sponge carrier material prepared above was evacuated at 100° C. for 20 hours to completely open the internal pores. Then the vacuum treated carbon nanotube sponge carrier material and liquid metal Bi 50 Pb 27 Sn 13 Cd 10 At the same time, it is placed in a vacuum flask and heated to 75°C to melt it. In a vacuum environment, the liquid metal Bi 50 Pb 27 Sn 13 Cd 10 Adsorption is restricted in the pores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com