Carbon dioxide drive injection well annular protective liquid and preparation method and use method thereof

An annular protective fluid and carbon dioxide technology, which is applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc. Reduce casing damage, facilitate large-scale application, and facilitate on-site maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

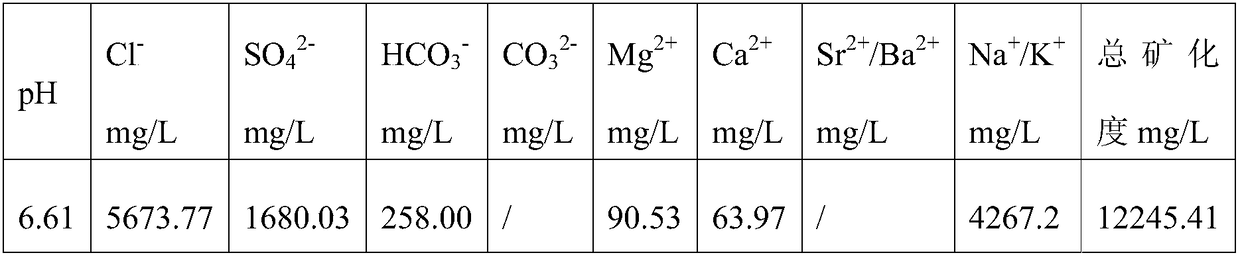

Method used

Image

Examples

Embodiment 1

[0046] A carbon dioxide flooding injection well annulus protection fluid is composed of the following substances by weight percentage:

[0047] 2% modified imidazoline derivatives;

[0048] 1% alkylphenol polyoxyethylene ether phosphate;

[0049] 5% hexamethylenetetramine;

[0050] 3% diethylenetriaminepentamethylene phosphoric acid;

[0051] 89% diesel.

[0052] Wherein, the modified imidazoline derivative is imidazoline phosphate.

[0053] In this example, the preparation method of the annulus protection fluid for carbon dioxide flooding injection wells is as follows:

[0054] 1) Under normal temperature and pressure, first stir the modified imidazoline derivative and alkylphenol polyoxyethylene ether phosphate with diesel oil in the reactor until completely dissolved;

[0055] 2) Under continuous stirring, add hexamethylenetetramine and diethylenetriamine pentamethylene phosphoric acid to the step-by-step reactor, stir while adding, and mix well to obtain the product. ...

Embodiment 2

[0065] A carbon dioxide flooding injection well annulus protection fluid is composed of the following substances by weight percentage:

[0066] 1% modified imidazoline derivatives;

[0067] 3% Alkylphenol Ethoxylate Phosphate;

[0068] 2% hexamethylenetetramine;

[0069] 1% diethylenetriaminepentamethylene phosphoric acid;

[0070] 93% diesel.

[0071] Wherein, the modified imidazoline derivative is mercaptobenzothiazole imidazoline.

[0072] In this example, the preparation method of the annulus protection fluid of the carbon dioxide flooding injection well is the same as that in Example 1.

[0073] In this example, the performance test of the annulus protection fluid of the carbon dioxide flooding injection well was carried out using the method and conditions in Example 1, and the test results showed that:

[0074] In the experiment, CO 2 The partial pressure is 10MPa, the experiment time is 14d, and the injected water is 10%. The experimental results show that when t...

Embodiment 3

[0077] A carbon dioxide flooding injection well annulus protection fluid is composed of the following substances by weight percentage:

[0078] 0.5% modified imidazoline derivatives;

[0079] 5% alkylphenol ethoxylate phosphate;

[0080] 3% hexamethylenetetramine;

[0081] 2% diethylenetriaminepentamethylene phosphoric acid;

[0082] 89.5% diesel.

[0083] Wherein, the modified imidazoline derivative is thioureidoimidazoline benzoate.

[0084] In this example, the preparation method of the annulus protection fluid of the carbon dioxide flooding injection well is the same as that in Example 1.

[0085] In this example, the performance test of the annulus protection fluid of the carbon dioxide flooding injection well was carried out using the method and conditions in Example 1, and the test results showed that:

[0086] In the experiment, CO 2 The partial pressure is 10MPa, the experiment time is 14d, and the injected water is 10%. The experimental results show that when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com