Treatment structure and method of high-strength water-permeable fiber concrete pipe gravel core pile soft thick soil base

A technology of concrete pipe piles and permeable concrete, which is applied in foundation structure engineering, sheet pile walls, soil protection, etc., to achieve the effects of increasing friction, reducing total settlement, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be described below in conjunction with specific embodiments.

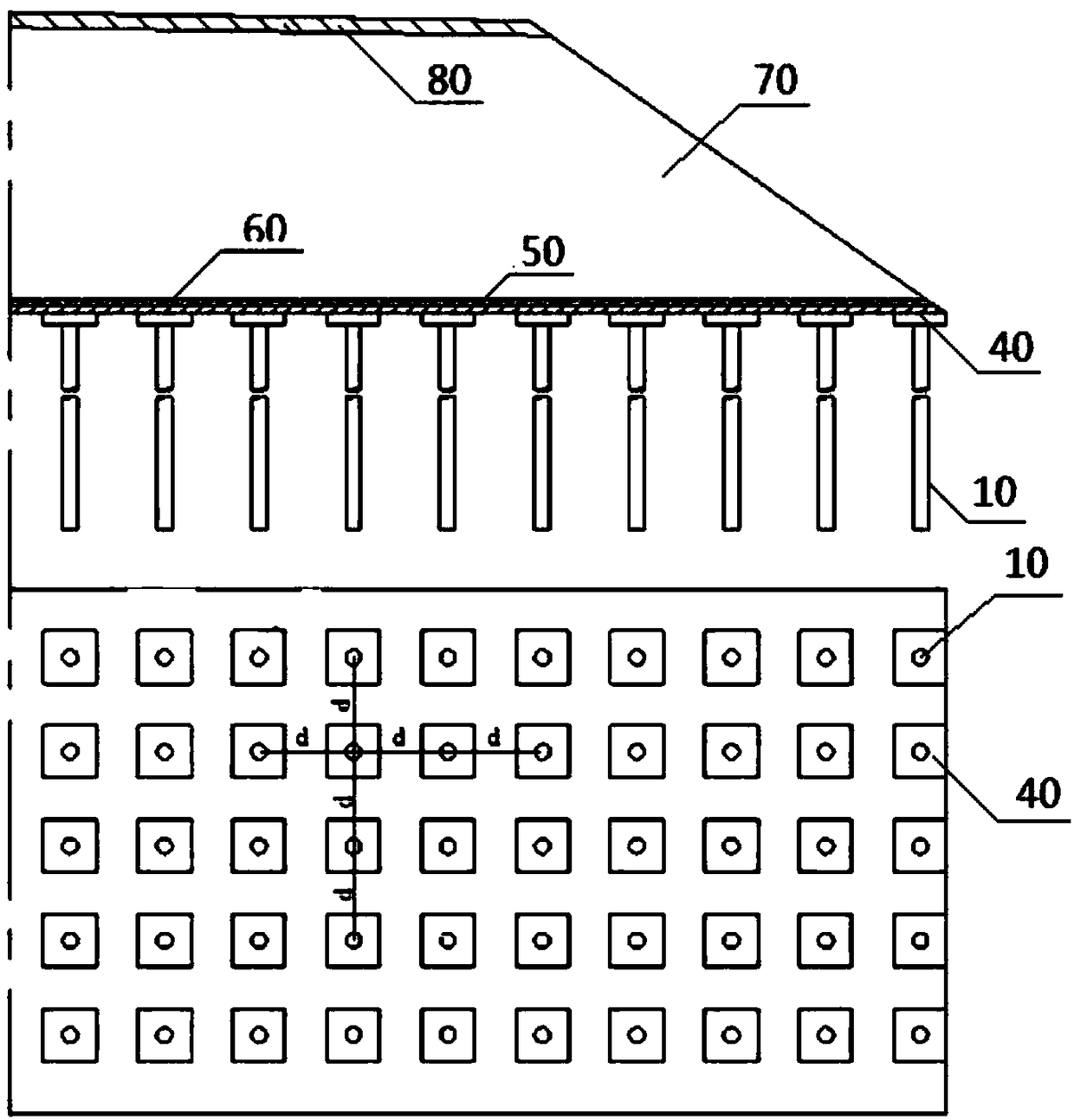

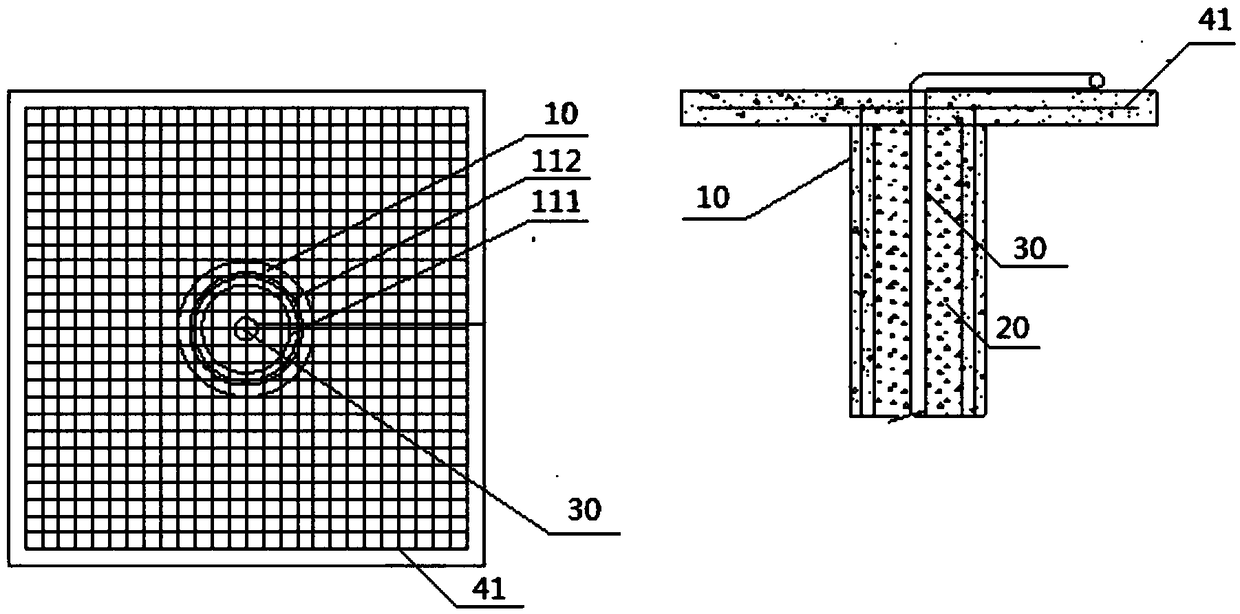

[0031] Such as figure 1 and Figure 8 As shown, it is a structural schematic diagram of the soft and thick soil foundation treatment structure of the high-strength permeable fiber concrete pipe crushed stone core pile according to the present invention:

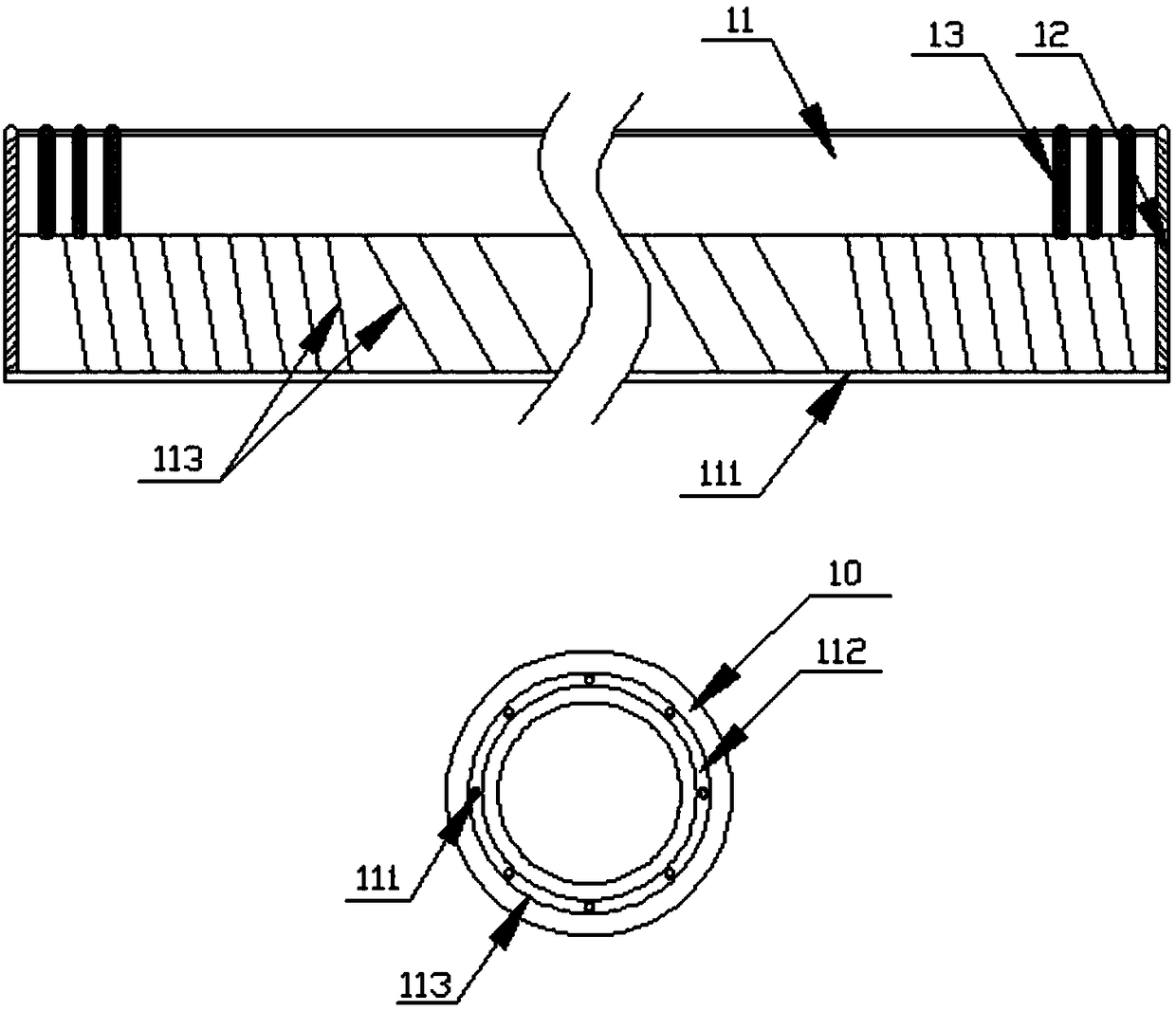

[0032] The soft and thick soil foundation treatment structure of the high-strength permeable fiber concrete pipe crushed stone core pile of the present invention, the soft foundation treatment structure includes high-strength permeable fiber concrete pipe pile 10, gravel in the official cavity 20, soft permeable blind pipe 30, and permeable concrete Pile cap 40, gravel cushion 50 and two-way steel-plastic grid 60, the gravel 20 is filled in the high-strength permeable fiber concrete pipe pile 10, and the soft permeable blind pipe 30 is arranged on the high-strength permeable fiber concrete pipe In the pile 10, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com