Heavy-load fluorine lined magnetic force pump

A fluorine-lined magnetic force and heavy-duty technology, which is applied in the field of heavy-load fluorine-lined magnetic pumps, can solve problems such as insufficient mechanical strength, and achieve the effects of wide application range, reasonable cycle, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

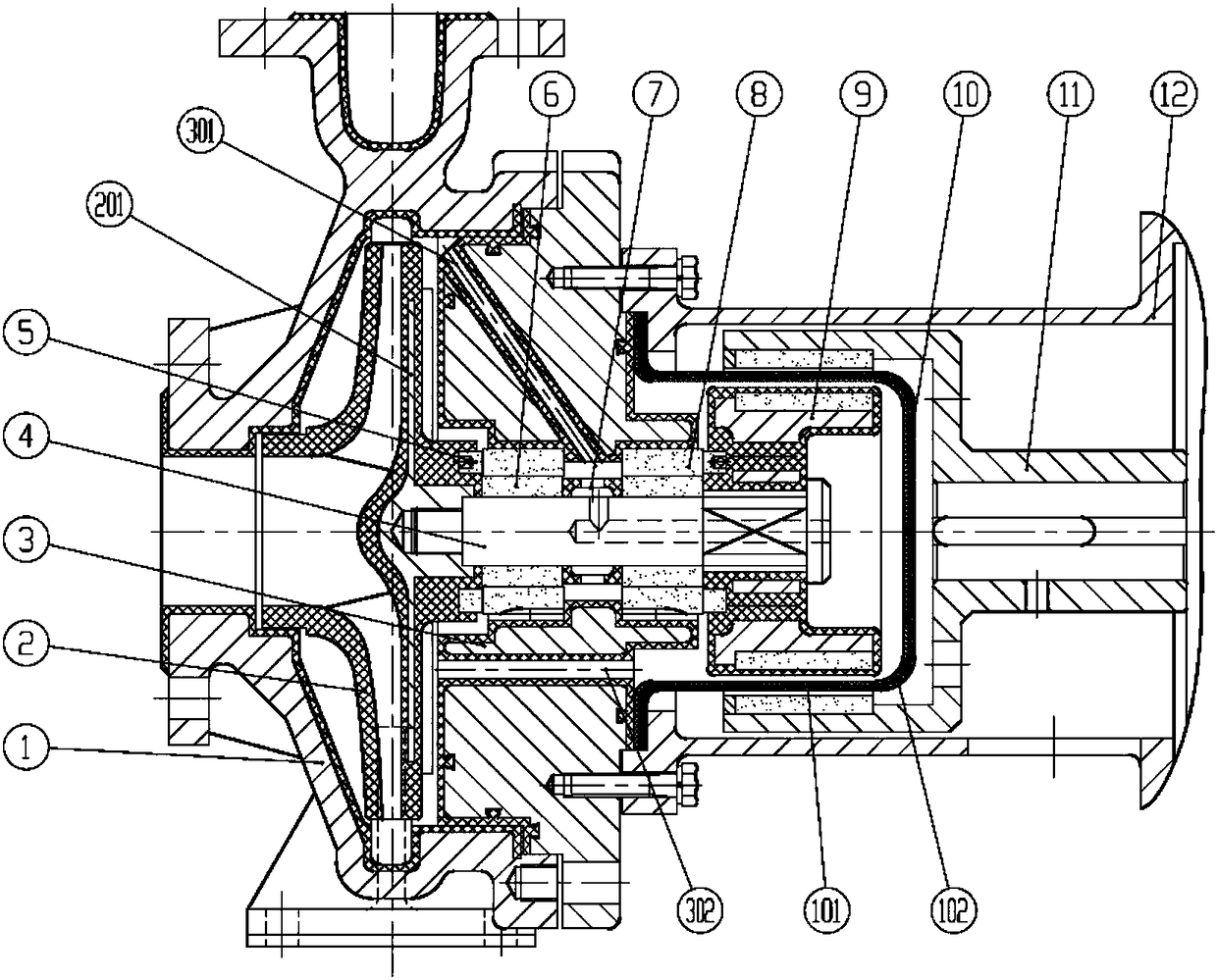

[0017] see figure 1 , the heavy-duty fluorine-lined magnetic pump of the present invention includes a pump body 1, an impeller 2, a pump shaft 4, an inner magnetic rotor assembly 9, a spacer sleeve assembly 10, an outer magnetic rotor assembly 11 and a coupling frame 12; A reinforced iron frame 201 is provided inside.

[0018] The spacer sleeve assembly 10 in the present invention is composed of an inner sleeve 101 and an outer sleeve 102 with lining strength.

[0019] In the present invention, the impeller 2 and the inner magnetic rotor assembly 9 are installed on both ends of the pump shaft 4 respectively, and a thrust plate 5 , a shaft sleeve 6 and a gear sleeve 7 are arranged in the middle.

[0020] The present invention also includes an independently arranged intermediate body 3 on which a bearing sleeve 8 is installed. The intermediate body 3 is provided with circulation holes 301 and return holes 302 .

[0021] When the fluorine-lined magnetic pump of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com