Novel high-temperature resistance garbage incinerator

A technology of waste incinerator and high temperature resistance, which is applied to incinerators, grate, combustion methods, etc., can solve the problems of incombustibility of the grate and inconvenient use, so as to solve the problem of the incompatibility of the grate and the inconvenience of use. , The effect of preventing incineration deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

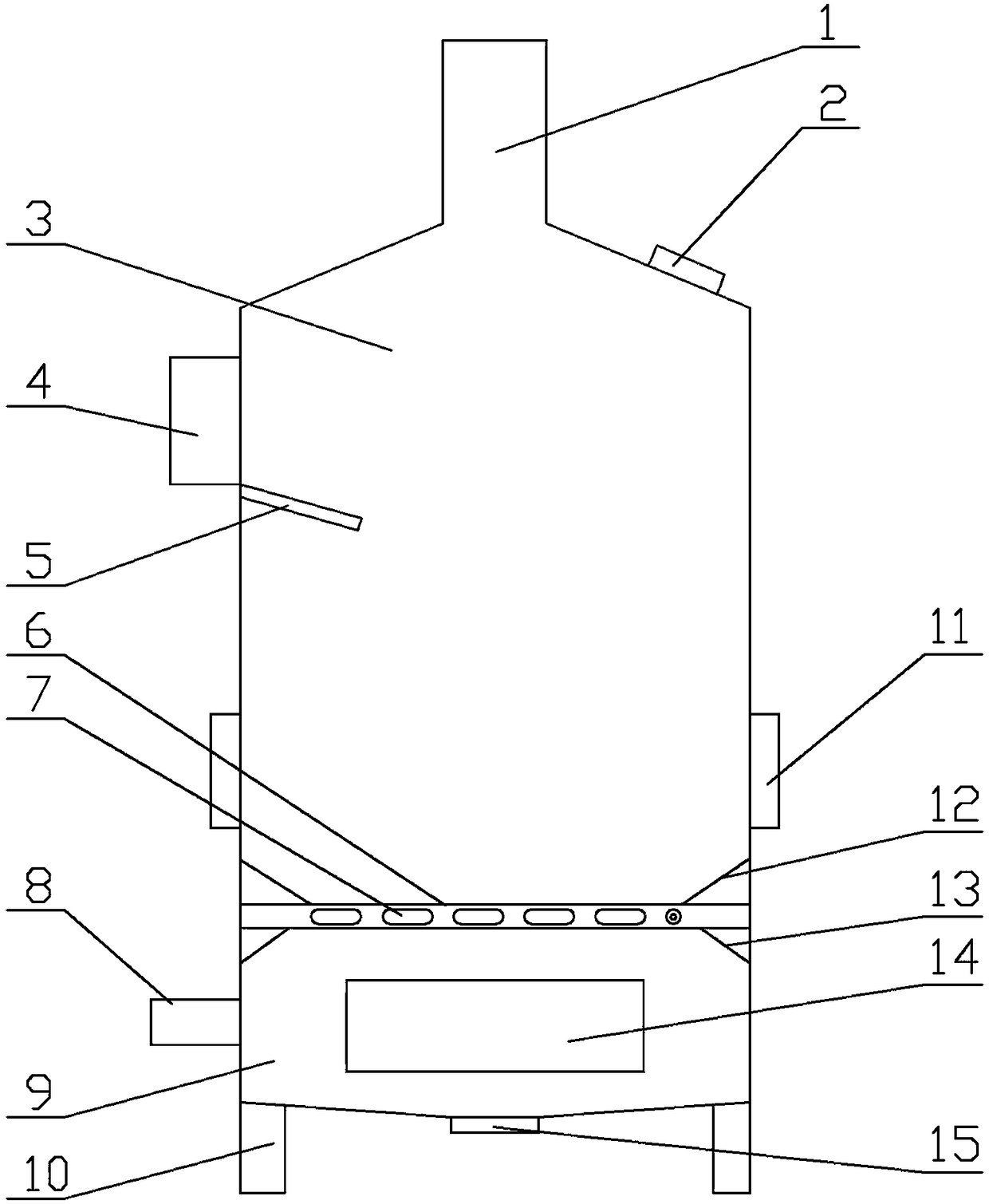

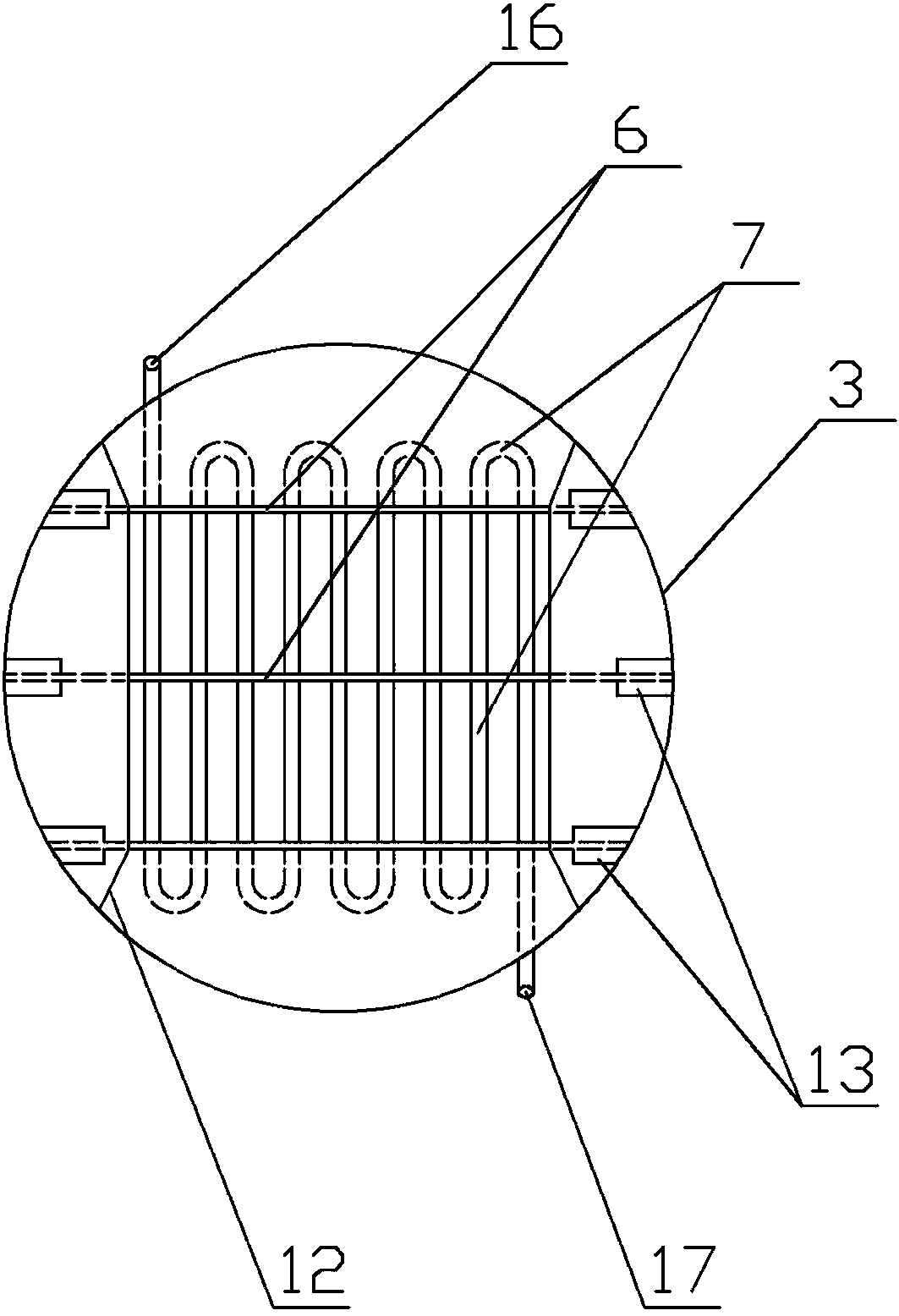

[0026] according to figure 1 and figure 2 , a new type of high-temperature-resistant garbage incinerator, which includes a body of furnace 3 and ash box 9; The fire grate includes a bracket 6 and a plurality of hollow bars 7 that run through the bracket; the hollow bars 7 are connected in series through elbows; A water outlet 16 and a water outlet 17; the support 6 is vertically connected to the side wall of the furnace body 3, and a reinforcing plate 13 is provided below the joint; a closing plate 12 is provided above the support.

[0027] During the combustion process, the hollow grate 7 starts water circulation through the water inlet 16 and the water outlet 17, which effectively prevents the grate from being burned out, and the circulating hot water can also be recycled.

[0028] A smoke pipe 1 is provided on the furnace body 3, and an air inlet pipe 8 is provided in the ash box 9.

[0029] The body of furnace 3 is provided with an inspection door 11 , and the ash box ...

Embodiment 2

[0037] The hollow furnace bars used in high-temperature-resistant garbage incinerators are prepared according to the following process:

[0038] Take Cu-Fe master alloy (CuFe10) 1000kg, Cu-Cr master alloy (CuCr10) 200kg, Cu-Mn master alloy (CuMn30) 50kg, Al-Ti-B master alloy (AlTi5B1) 10kg; put them into the electric melting furnace in turn, Raise the temperature, control the melting temperature to 1200°C, after 3 hours of melting, take out the prepared melt, pour it into the mold, cool to 800°C at a cooling rate of 40°C / s, keep it warm for 100s, and then heat it at 25°C / s Cool to 300°C, keep warm for 200s, then cool to room temperature at a speed of 20°C / s, demould to get the blank; heat the blank to 500°C, heat up at a rate of 2°C / s, keep warm for 2 hours, and then Cool down to 400°C with a cooling rate of 5°C / s and keep warm for 5 hours, then raise the temperature to 450°C with a heating rate of 2°C / s and keep warm for 4 hours, then cool down to 300°C with a cooling rate of...

Embodiment 3

[0040] The performance test of hollow furnace bar alloy material of the present invention:

[0041] Set up control groups, control group 1: no addition of Al-Ti-B master alloy, the rest is the same as in Example 2; control group 2: no addition of Cu-Mn master alloy, the rest is the same as in embodiment 2. The performance parameters of each group are shown in Table 1:

[0042] Table 1

[0043] group

Hardness HRC

Tensile strengthMpa

Fracture toughnessMPa / m 1 / 2

Example 2

51.3

597.8

11.3

31.2

Control group 1

47.5

553.7

9.7

25.4

Control group 2

40.1

513.9

10.2

27.9

[0044] Conclusion: Compared with the control group 1-2, the hardness of the alloy material of the present invention is HRC 51.3; the tensile strength is 597.8Mpa, the impact toughness is 11.3J / cm2; the fracture toughness is 31.2MPa / m 1 / 2 , the mechanical properties are better, the service life is improved,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com