Mechanical magneto-oxygen meter pretreatment system for on-line detection of oxygen content in cracking gas

A technology of surface pretreatment and oxygen content, which is applied in the field of chemical gas detection, can solve the problems of inaccurate online analysis of oxygen content, unfavorable device normal operation, and display lag, so as to avoid unqualified water removal and reduce the time for replacing filter packing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

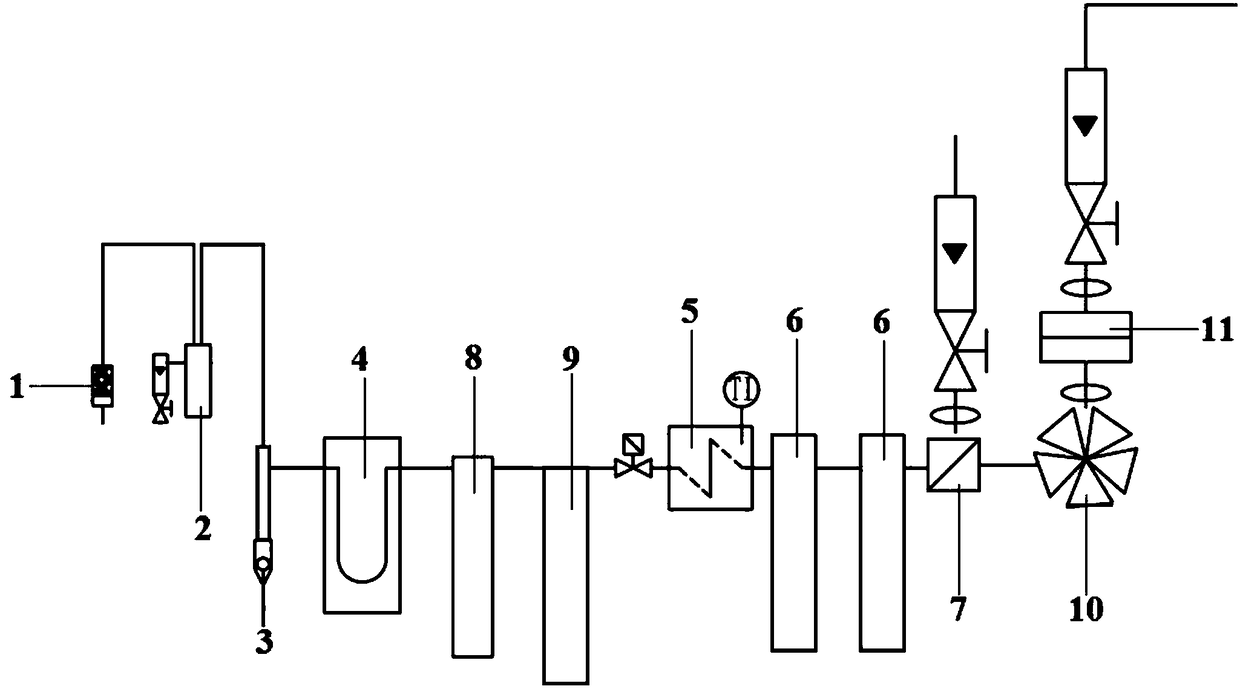

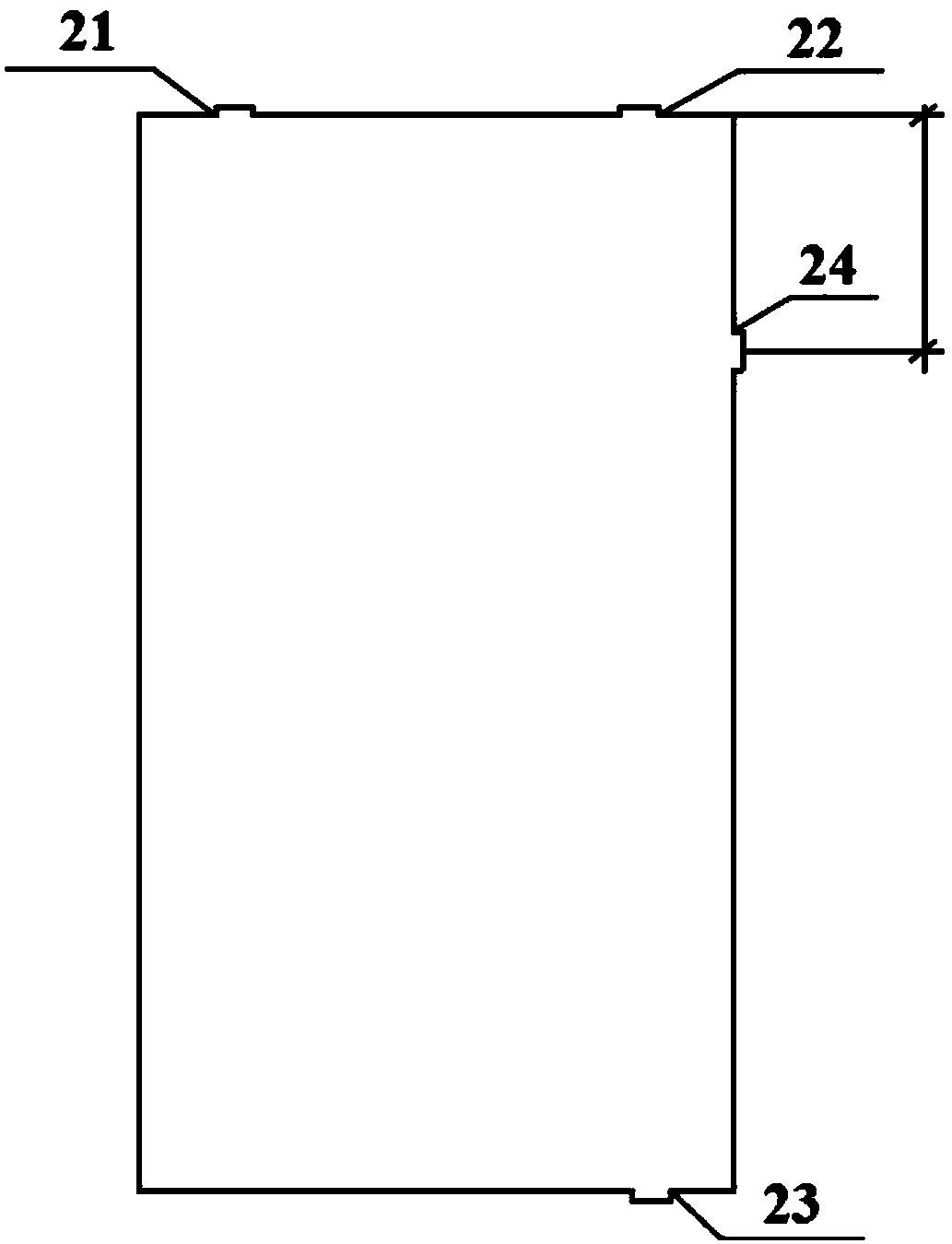

[0032] This embodiment relates to a mechanical magnetic oxygen meter pretreatment system for on-line detection of oxygen content in cracked gas, and its structural diagram is as follows figure 1 : Including coarse filter 1, water scrubber 2, gas-liquid separation tank 3, water eliminator, bypass filter 7, analyzer five-way valve 10 connected in sequence, the outlet of coarse filter 1 is connected to the inlet of water scrubber 2, The outlet of the water washer 2 is connected to the inlet of the gas-liquid separation tank 3, wherein the water washer 2 includes a gas sample inlet 21, a gas sample outlet 22, an overflow water sample inlet 23 and an overflow water sample outlet 24, and the water washer 2 has a diameter of 90mm. The length is 1200mm, the overflow water sample outlet 23 of the water washer is 25mm in size, and the overflow water sample outlet 23 of the water washer is 40mm in height from the gas sample outlet 22; The primary water eliminator 6, the inlet of the prim...

Embodiment 2

[0034] This embodiment relates to a mechanical magnetic oxygen meter pretreatment system for on-line detection of oxygen content in cracked gas, and its structural diagram is as follows figure 1 : Including coarse filter 1, water scrubber 2, gas-liquid separation tank 3, water eliminator, bypass filter 7, analyzer five-way valve 10 connected in sequence, the outlet of coarse filter 1 is connected to the inlet of water scrubber 2, The outlet of the water washer 2 is connected to the inlet of the gas-liquid separation tank 3, wherein the water washer 2 includes a gas sample inlet 21, a gas sample outlet 22, an overflow water sample inlet 23 and an overflow water sample outlet 24, and the water washer 2 has a diameter of 80mm. The length is 1000mm, the overflow water sample outlet 23 of the water washer is 20mm in size, and the overflow water sample outlet 23 of the water washer is 80mm in height from the gas sample outlet 22; The primary water eliminator 6, the inlet of the prim...

Embodiment 3

[0036] This embodiment relates to a mechanical magnetic oxygen meter pretreatment system for on-line detection of oxygen content in cracked gas, and its structural diagram is as follows figure 1 : Including coarse filter 1, water scrubber 2, gas-liquid separation tank 3, water eliminator, bypass filter 7, analyzer five-way valve 10 connected in sequence, the outlet of coarse filter 1 is connected to the inlet of water scrubber 2, The outlet of the water washer 2 is connected to the inlet of the gas-liquid separation tank 3, wherein the water washer 2 includes a gas sample inlet 21, a gas sample outlet 22, an overflow water sample inlet 23 and an overflow water sample outlet 24, and the water washer 2 has a diameter of 80mm. The length is 1000mm, the overflow water sample outlet 23 of the water washer is 25mm in size, and the overflow water sample outlet 23 of the water washer is 200mm high from the gas sample outlet 22; the water eliminator includes a first water eliminator 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com