Fiber bragg grating humidity sensor with non-grating areas being coated with polyimide

A technology of humidity sensor and optical fiber grating, which is applied in instruments, scientific instruments, and material analysis through optical means, etc., can solve the problems of complex packaging structure, poor hysteresis of sensors, and uneven edge warping of materials, etc. To achieve the effect of improving yield and comprehensive performance, broad application prospects, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure of the fiber grating humidity sensor of the present invention will be described in further detail below with reference to the accompanying drawings and specific implementations.

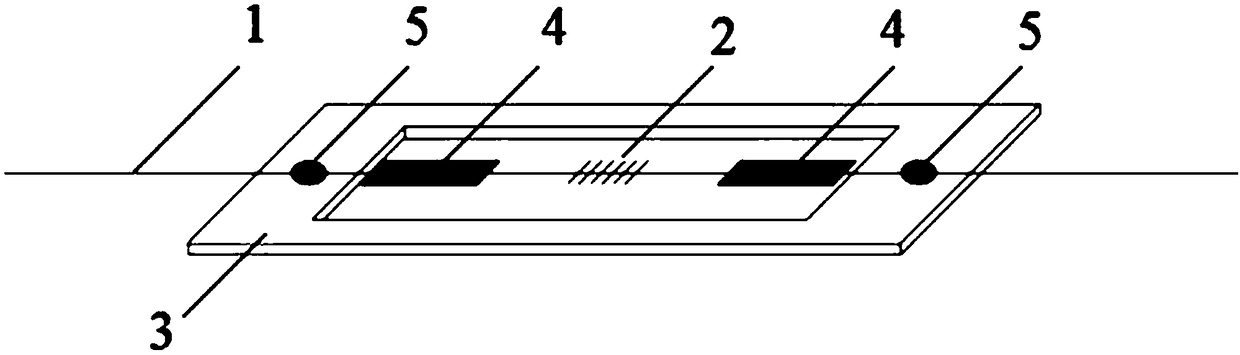

[0018] like figure 1 Shown is a schematic structural diagram of a fiber grating humidity sensor coated with polyimide in a non-grid area, including a single-mode optical fiber 1 and a hollow substrate 3, the single-mode optical fiber 1 is fixed on the hollow substrate 3, and the single-mode optical fiber 1. It is fixed on the hollow substrate 3 with UV ultraviolet glue 5, and the fiber Bragg grating 2 is laser engraved on the single-mode fiber 1 of the hollow part in the middle of the hollow substrate 3. The non-grid areas at both ends of the fiber Bragg grating 2 are respectively covered with polyamide. The imine film 4 forms a structure of "polyimide film-fiber grating-polyimide film". The "polyimide film-fiber grating-polyimide film" structure is pre-stressed first, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com