Detection device for detecting cracks in bottom surface of bridge

A detection device and bridge technology, which is applied to measurement devices, electrical devices, electromagnetic measurement devices, etc., can solve the problems of being easily affected by subjective factors, relying on personal experience, and high requirements for cameras, so as to reduce shooting costs and save money. Labor cost and the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

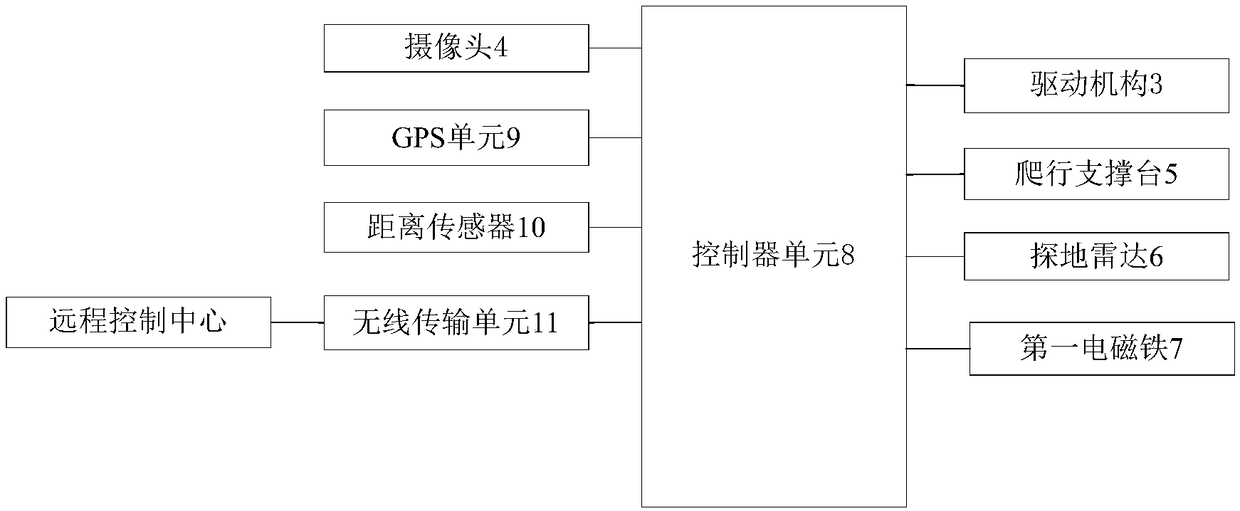

[0032] Most of the crack detection methods in the prior art have problems such as low detection accuracy and poor adaptability. The present invention proposes a detection device for cracks on the bottom of bridges. The detection components include several cameras and ground-penetrating radars. Preliminary detection; when a crack is detected, the controller unit first generates the walking track of the crawling support platform according to the image captured by the camera, and then drives the crawling support platform to move along the walking track to the crack to detect the width and depth of the crack. Not only can it be applied to the detection of large-span and irregular cracks, but it also greatly improves the detection accuracy and provides a strong guarantee for the prediction of bridge road surface disasters; the whole process is automatically processed without manual participation, which greatly saves labor costs.

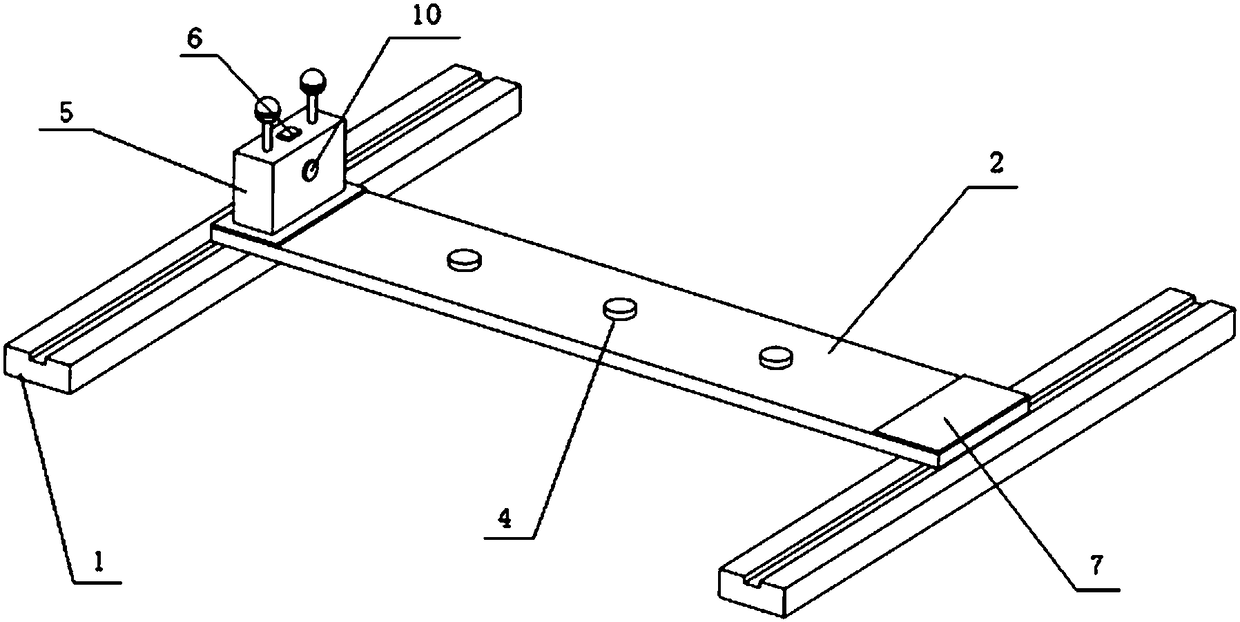

[0033] Specifically, such as Figure 1-2 As shown, ...

Embodiment 2

[0043] Based on Embodiment 1, in order to improve detection efficiency, reduce detection power consumption, and prolong detection time, the detection device for cracks on the bottom surface of the bridge also includes two distance sensors 10, and the two distance sensors 10 are respectively arranged on the crawling support platform 5, when the crack detection is completed, the two distance sensors 10 send detection signals respectively, and the controller unit 8 judges the first electromagnet 7 that is closer to the crawling support platform 5, and then controls the crawling support platform 5 Move to the position where the first electromagnet 7 is located, and then start the first electromagnet 7 and the second electromagnet to realize fixing the crawling support platform 5 on the support frame 2 .

Embodiment 3

[0045] Based on Embodiment 1 or Embodiment 2, in order to be able to detect at night, the detection device for cracks on the bottom surface of the bridge also includes several lighting lamps (not shown in the figure), the number of the lighting lamps is the number of cameras 4 twice, every two illuminating lights are installed on both sides of a camera 4 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com