Photoelectric conversion machine with function of tightly plugging optical fiber connectors

An optical fiber connector and converter technology, which is used in optical fiber transmission, coupling of optical waveguides, light guides, etc., can solve problems such as falling off and loose fiber connectors, and achieve the effect of preventing loosening or adjusting the tightness, reliable connection, and stable movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

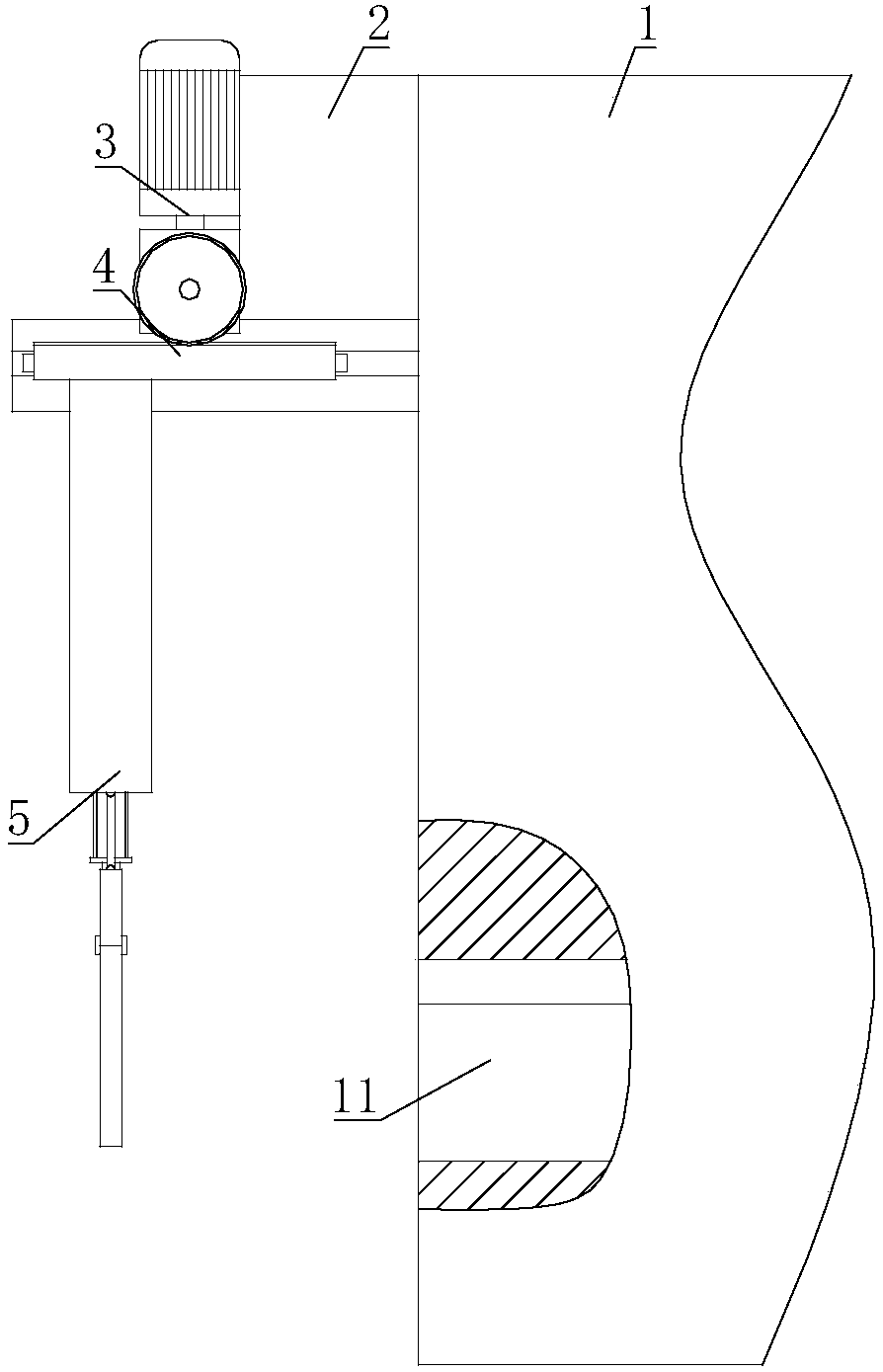

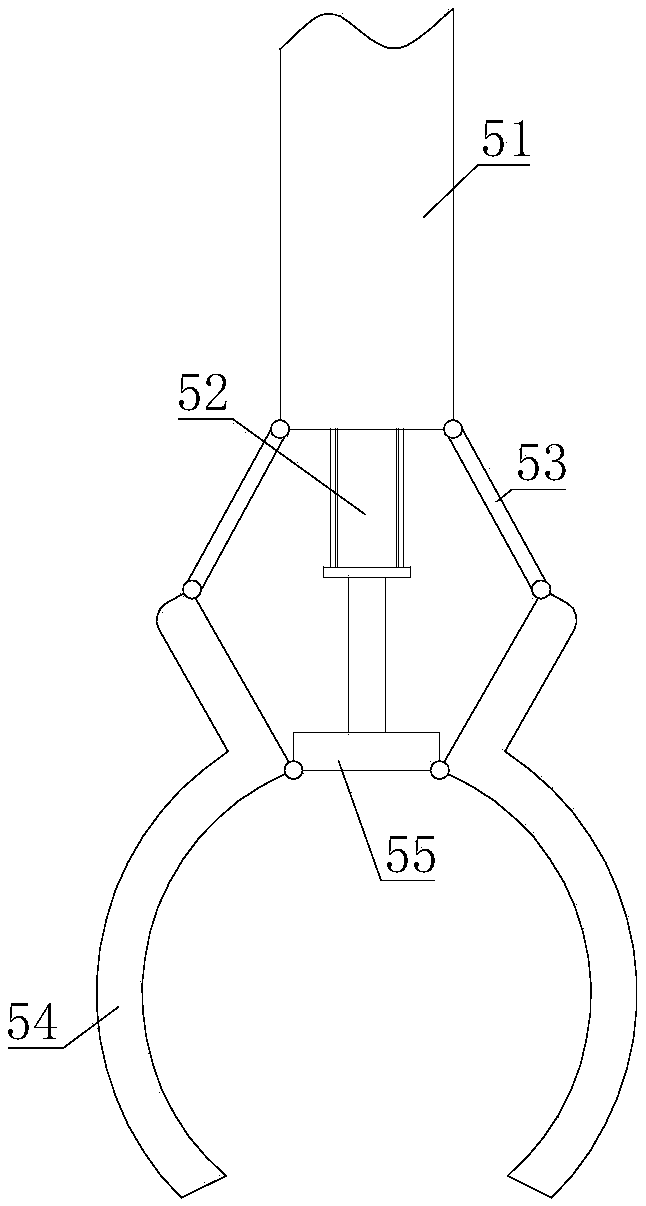

[0024] A photoelectric converter capable of inserting optical fiber connectors tightly, including a main body 1 of the converter, on which an optical fiber interface 11 is arranged; the main body 1 of the converter is connected with a mounting plate 2, and a driving mechanism 3 is installed on the mounting plate 2 , the output end of the driving mechanism 3 is connected to the rack and pinion mechanism 4, and the other end of the rack and pinion mechanism 4 is connected to the clamping mechanism 5 for clamping the optical fiber connector.

[0025] The driving mechanism 3 of the present invention can drive the rack and pinion mechanism 4 to move, and the rack and pinion mechanism 4 drives the clamping mechanism 5 to move. Therefore, the optical fiber connector clamped by the clamping mechanism 5 can move towards the direction close to the optical fiber slot, and the optical fiber connector can be inserted into the optical fiber interface more firmly, avoiding the situation that ...

Embodiment 2

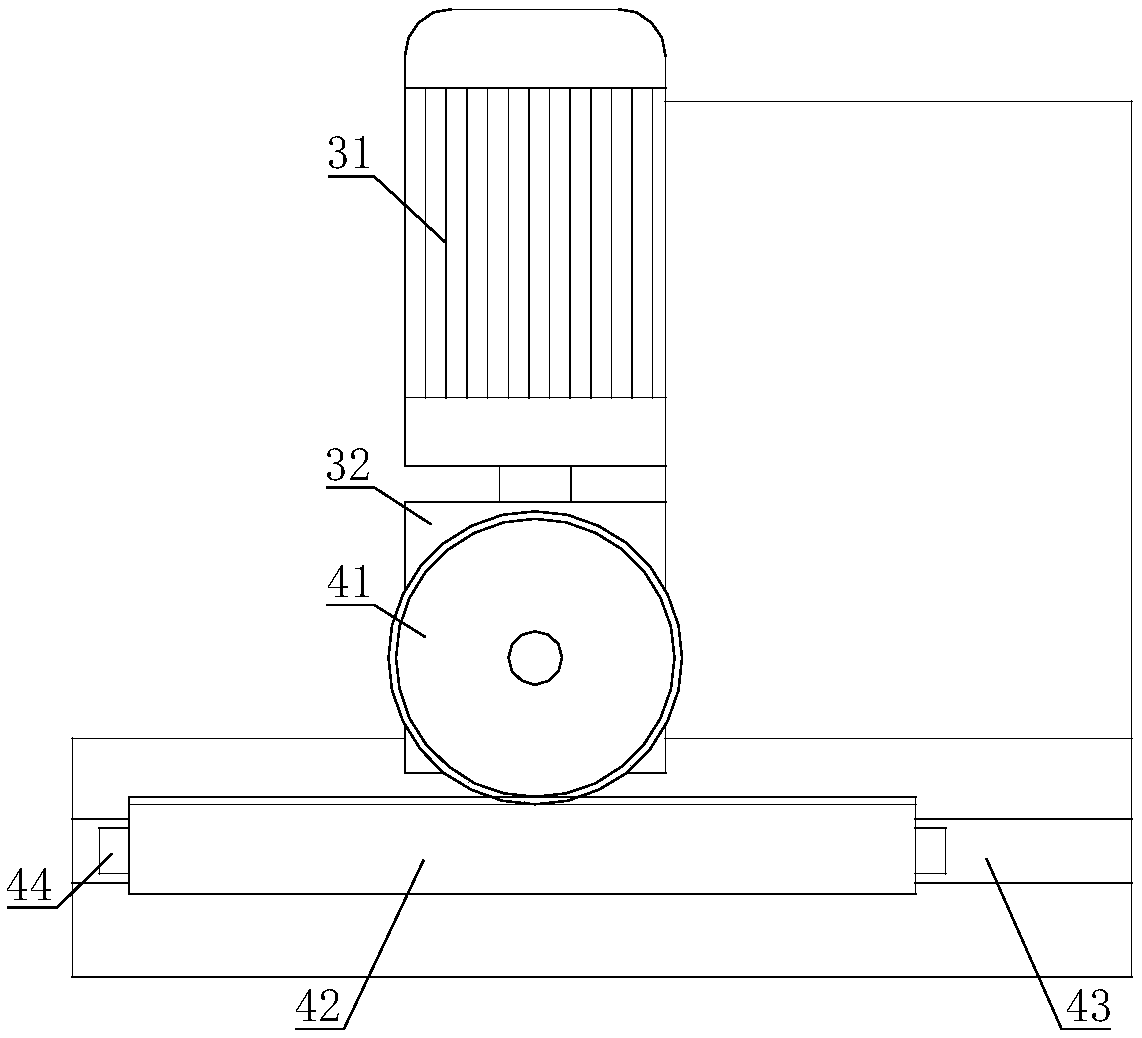

[0027] On the basis of Embodiment 1, the drive mechanism 3 includes a motor 31, the output shaft of the motor 31 is connected with a speed reducer 32, the motor 31 and the speed reducer 32 are all installed on the mounting plate 2, the output shaft of the speed reducer 32 and the gear The gear of the rack mechanism 4 is connected.

[0028] When the motor 31 is started, the motor 31 drives the reducer 32 to act, and the reducer 32 drives the rack and pinion mechanism 4 to operate, so that the clamping mechanism 5 and the optical fiber connector can move accurately under the drive of the rack and pinion to ensure smooth plugging, or It is used to adjust the tightness of the optical fiber connector inserted into the optical fiber interface 11.

Embodiment 3

[0030] On the basis of Embodiment 1 or Embodiment 2, the rack and pinion mechanism 4 includes a gear 41, the gear 41 is connected to the output shaft of the drive mechanism 3, the gear 41 is engaged with a rack 42, and the clamping mechanism 5 is fixed on the rack 42 ; the mounting plate 2 is also connected with a chute 43 , the rack 42 is fixed with a slide bar 44 , and the slide bar 44 is sleeved in the chute 43 .

[0031] When the driving mechanism 3 drives the gear 41 to rotate, the rack 42 moves horizontally under the drive of the gear 41, so that the rack 42 can drive the clamping mechanism 5 and the optical fiber joint to move, thereby achieving the purpose of preventing loosening of the optical fiber joint or adjusting the tightness. During the moving process of the rack 42, the slide bar 44 always slides in the chute 43, so that the rack 42 moves more smoothly, and also ensures that the optical fiber connector does not shake greatly during the moving process, reducing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com