Method of improving bridging short circuit between metals through film forming machine

A film forming machine and metal-to-metal technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as short circuit of wires, inability to carve TiN, slow etching rate, etc., and achieve easy etching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

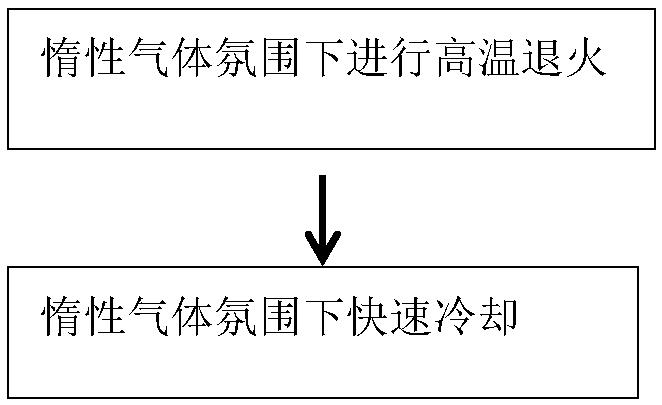

[0015] The method for improving the formation of bridging short circuits between metals by means of a film-forming machine in the present invention is applicable to AlCu or AlSiCu metal film layers. Specifically, a film forming machine is used to complete the deposition of the metal film layer. After the deposition of the metal film layer is completed, high-temperature annealing treatment is performed under an inert gas atmosphere. The film layer is cooled from the annealing temperature to room temperature.

[0016] For example, the AlCu metal film layer is annealed in a nitrogen atmosphere at 400°C. After the annealing is completed, the inert gas is quickly passed in for cooling, and the temperature of the metal film layer is lowered from 400°C to room temperature within 10 seconds. After the rapid cooling is completed, the metal film layer can be repaired to solve the problem of Cu precipitation.

[0017] The method of improving the formation of bridging and short circuits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com