Synthesis method and application of Cu octahedron PtCu-rich nano-catalyst for fuel cell

A nano-catalyst and fuel cell technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of no case for Cu-rich octahedral PtCu nanocatalysts, and achieve novel structure and high yield High, excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

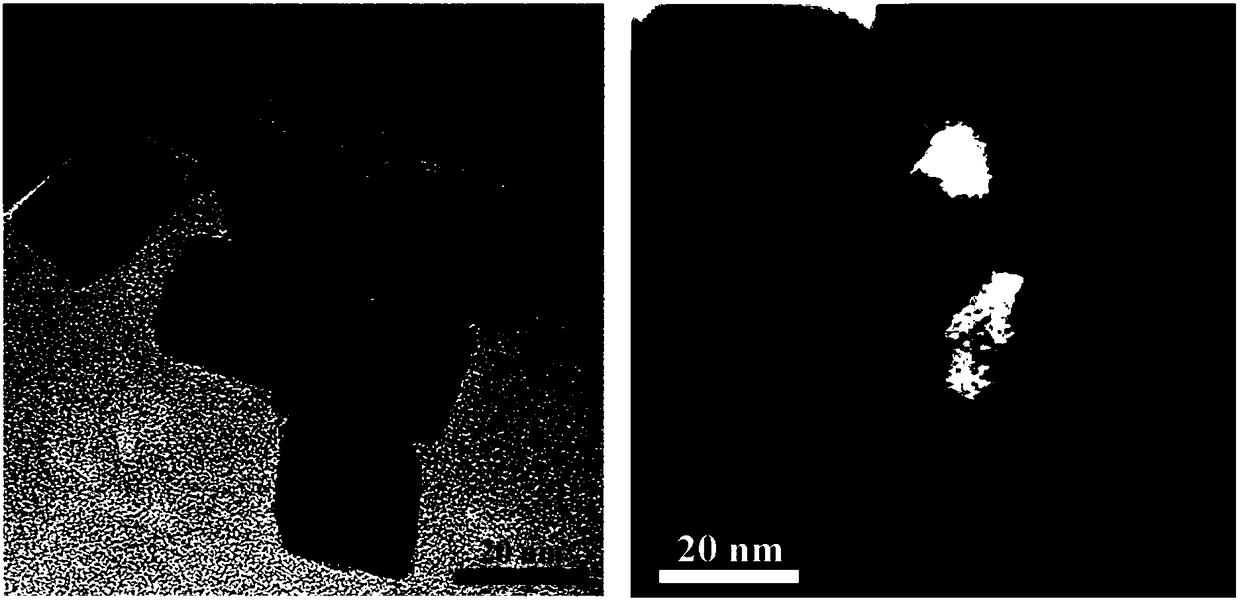

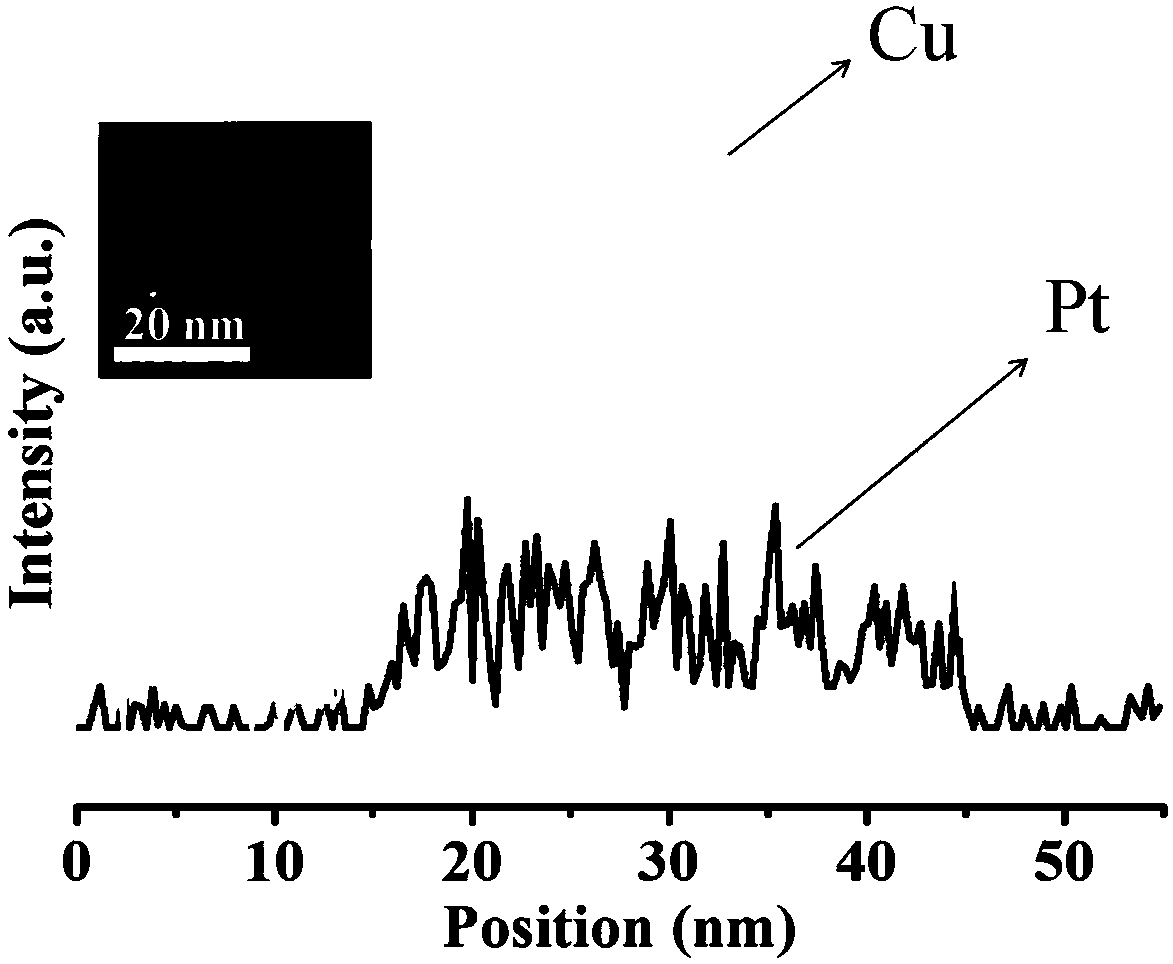

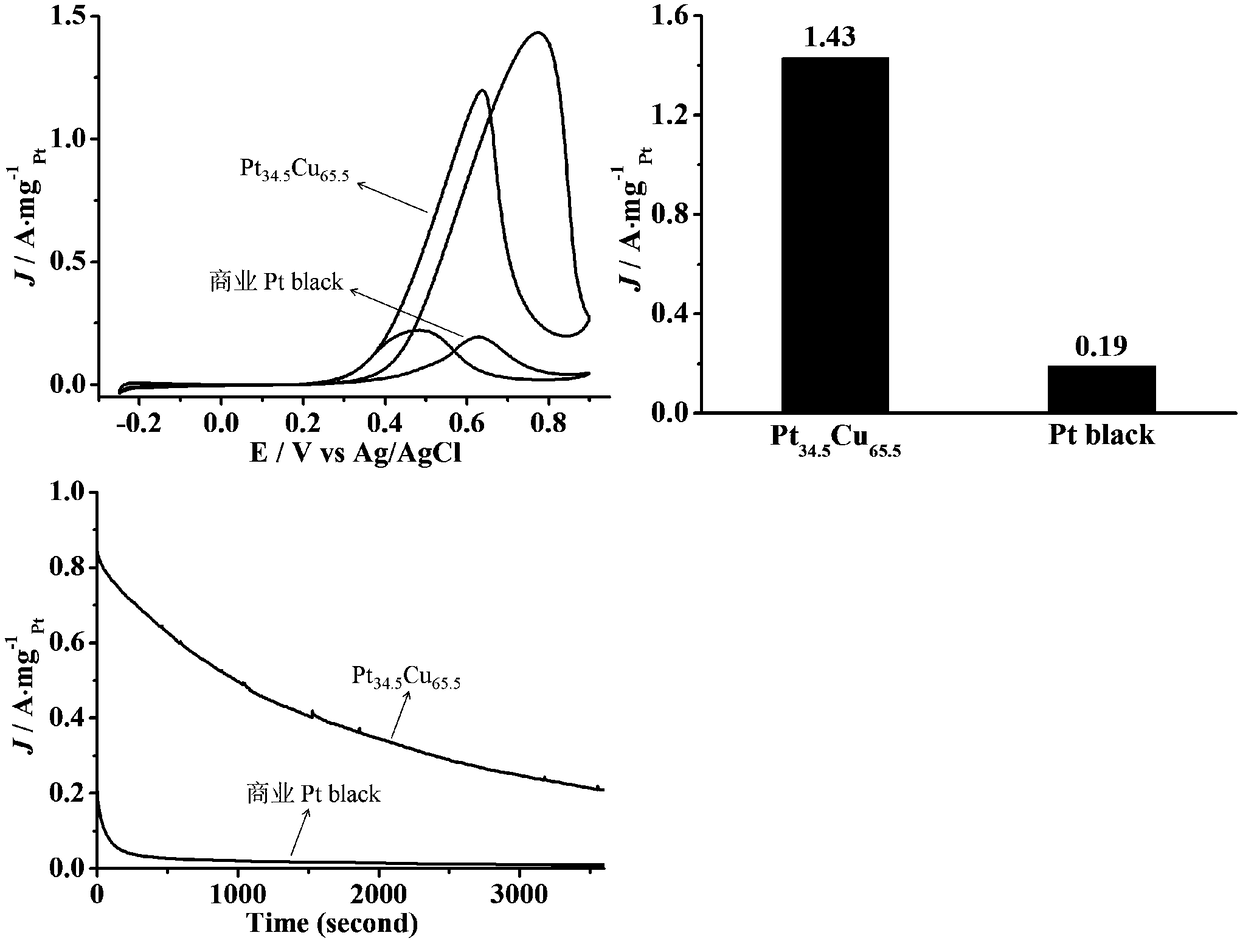

[0021] A kind of synthesis method of Cu-rich octahedral PtCu nano-catalyst is characterized in that it comprises the following steps:

[0022] (1) Add metal platinum salt and copper salt together into organic solvent DMF, the amount of metal salt precursor is 0.01-0.1mol, stir at room temperature for 5-8 minutes, the molar ratio of platinum salt precursor to copper salt precursor is 1:2; the amount of organic solvent DMF added needs to completely dissolve the metal platinum salt and copper salt;

[0023] (2) Add glucose and CTAB to the mixed solution obtained in step (1), stir at room temperature for 3-10 minutes, the molar ratio of glucose to CTAB is 5:1; the molar ratio of the amount of glucose added to the metal salt is : 5:1; the molar ratio of CTAB to metal salt is: 1:1.

[0024] (3) Add formaldehyde to the mixed solution obtained in step (2), stir at room temperature for 1 to 10 minutes, and the volume ratio of formaldehyde to DMF is 1:7;

[0025] (4) When the mixed so...

Embodiment 2

[0028] A kind of synthesis method of Cu-rich octahedral PtCu nano-catalyst is characterized in that it comprises the following steps:

[0029] (1) Add metal platinum salt and copper salt together into organic solvent DMF, the amount of metal salt precursor is 0.01-0.1mol, stir at room temperature for 5-8 minutes, the molar ratio of platinum salt precursor to copper salt precursor is 1:1; the amount of organic solvent DMF added needs to completely dissolve the metal platinum salt and copper salt;

[0030] (2) Add glucose and CTAB to the mixed solution obtained in step (1), stir at room temperature for 3-10 minutes, the molar ratio of glucose to CTAB is 5:1; the molar ratio of the amount of glucose added to the metal salt is : 10:1; the molar ratio of CTAB to metal salt is: 2:1;

[0031] (3) Add formaldehyde to the mixed solution obtained in step (2), stir at room temperature for 1 to 10 minutes, and the volume ratio of formaldehyde to DMF is 1:7;

[0032] (4) When the mixed s...

Embodiment 3

[0035] A kind of synthesis method of Cu-rich octahedral PtCu nano-catalyst is characterized in that it comprises the following steps:

[0036] (1) Add metal platinum salt and copper salt together into organic solvent DMF, the amount of metal salt precursor is 0.01-0.1mol, stir at room temperature for 5-8 minutes, the molar ratio of platinum salt precursor to copper salt precursor is 1:4; the amount of organic solvent DMF added needs to completely dissolve the metal platinum salt and copper salt;

[0037] (2) Add glucose and CTAB to the mixed solution obtained in step (1), and stir at room temperature for 3 to 10 minutes. The molar ratio of the amount of glucose added to the metal salt is 4:1; the molar ratio of CTAB to the metal salt The ratio is: 1:1;

[0038] (3) Add formaldehyde to the mixed solution obtained in step (2), stir at room temperature for 1 to 10 minutes, and the volume ratio of formaldehyde to DMF is 1:5;

[0039] (4) When the mixed solution obtained in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com