Lithium battery treatment system and treatment process

A processing system and lithium battery technology, applied in battery recycling, waste collector recycling, combined devices, etc., can solve incomplete recovery of positive and negative electrode powder and metal powder, incomplete recovery of positive and negative electrode materials, poor crushing effect, etc. problems, to achieve the effect of good recycling effect, simple and reasonable treatment process, and thorough treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

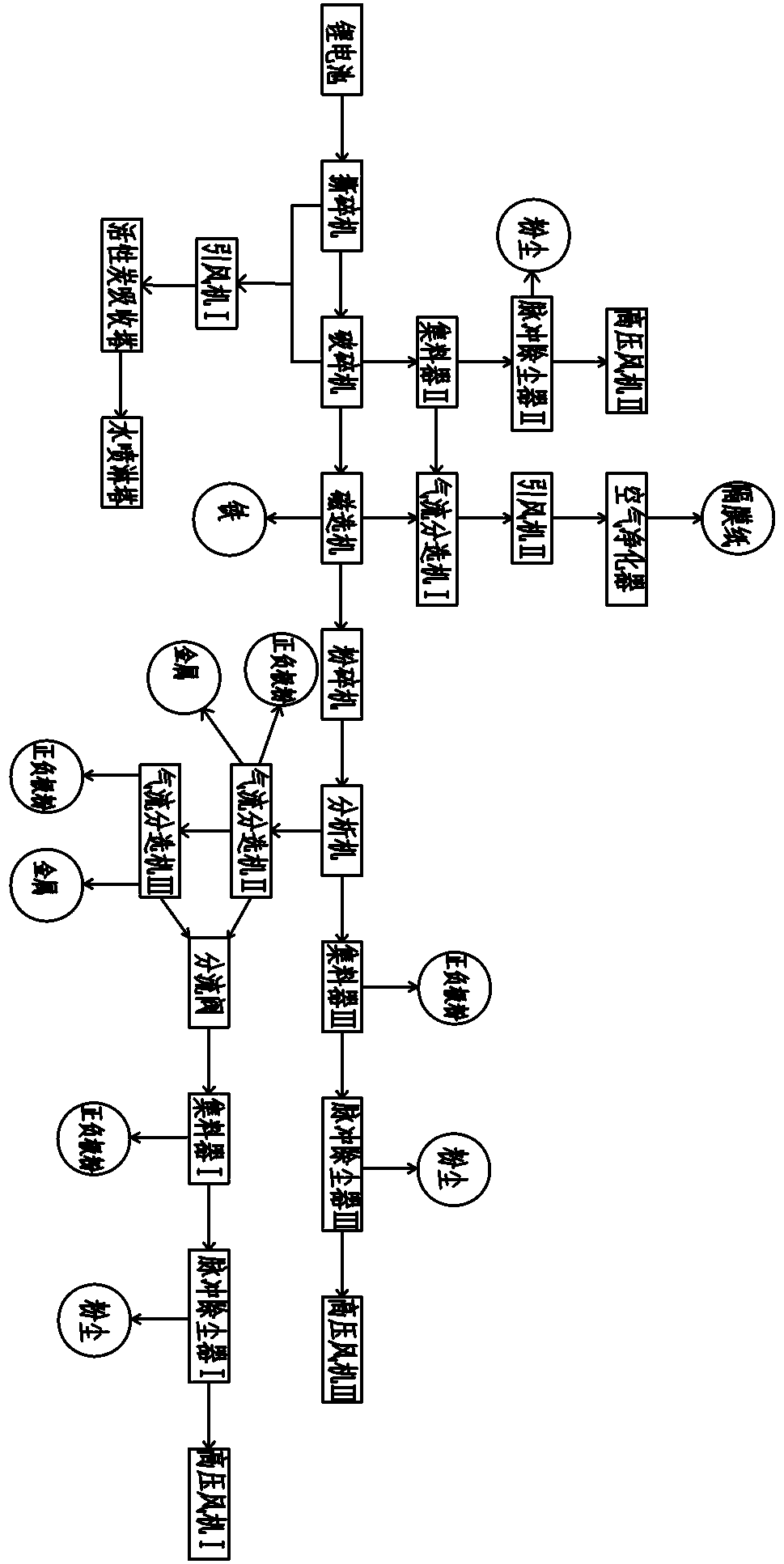

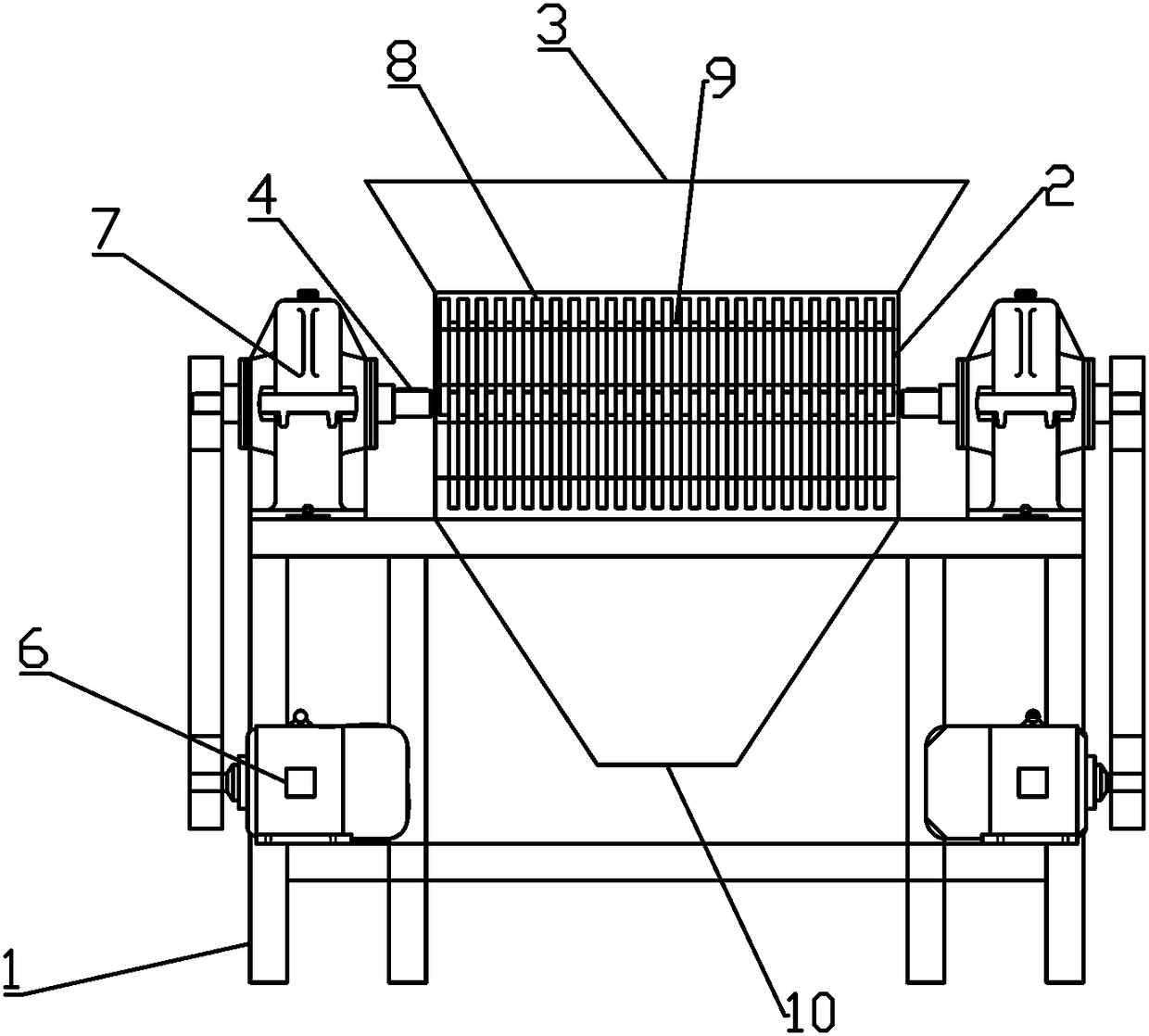

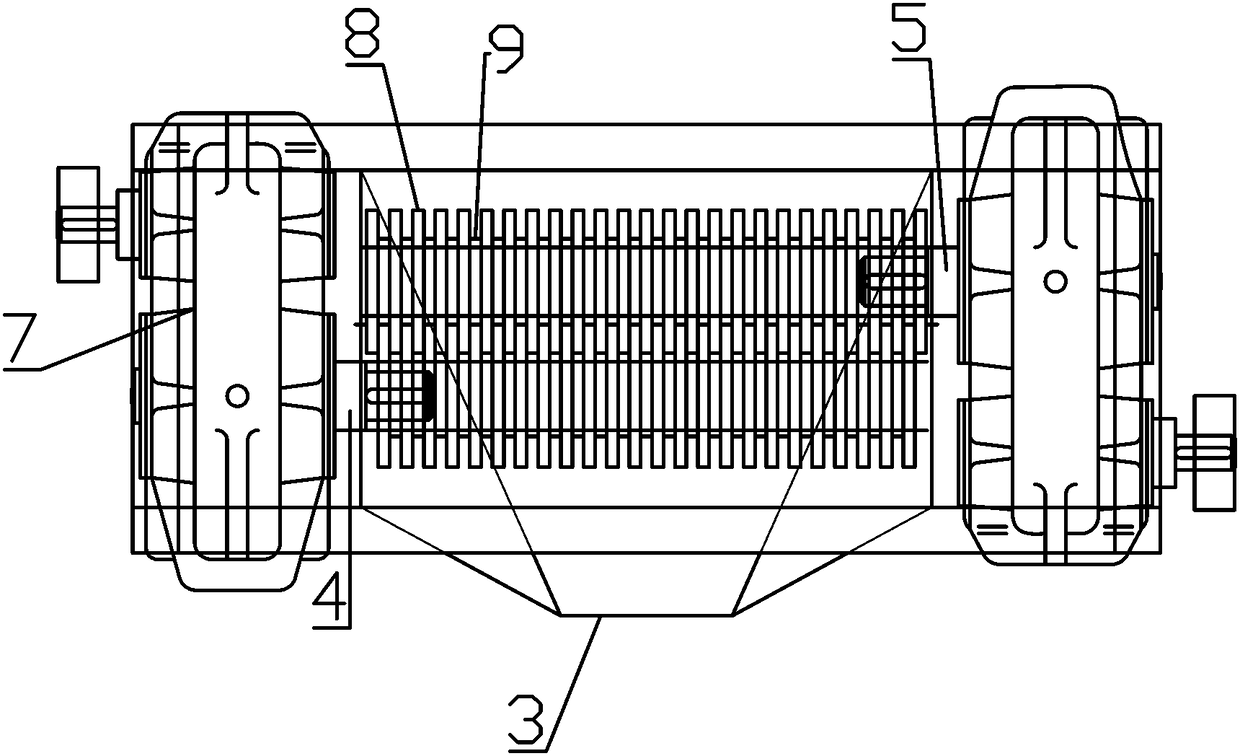

[0029] Embodiment 1: a kind of lithium battery processing system, such as Figure 1-6 , including shredders, crushers, magnetic separators, pulverizers, analyzers, sorting devices, diverter valves, collector Ⅰ, collector Ⅱ, collector Ⅲ, pulse dust collector Ⅰ, pulse dust collector Ⅱ , pulse dust collector Ⅲ, high pressure fan Ⅰ, high pressure fan Ⅱ, high pressure fan Ⅲ, air separator Ⅰ, air separator Ⅱ, air separator Ⅲ, induced draft fan Ⅰ and induced draft fan Ⅱ; shredder and crusher , magnetic separator, pulverizer, analyzer, sorting device, diverter valve, collector Ⅰ, pulse dust collector Ⅰ and high-pressure fan II are connected in sequence; collector Ⅰ and collector Ⅲ are also equipped with positive and negative The electrode powder outlet, the positive and negative electrode powder collected in the collector Ⅰ and the collector Ⅲ are discharged through the positive and negative electrode powder outlets, and the pulse dust collector Ⅰ, pulse dust collector Ⅱ and pulse dus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com