Blade manufacturing method and blade

A production method and blade technology, which can be applied to other household appliances, household appliances, household components, etc., can solve the problems of environmental pollution, increased labor costs, increased material costs, etc., and achieve the effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will now be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown.

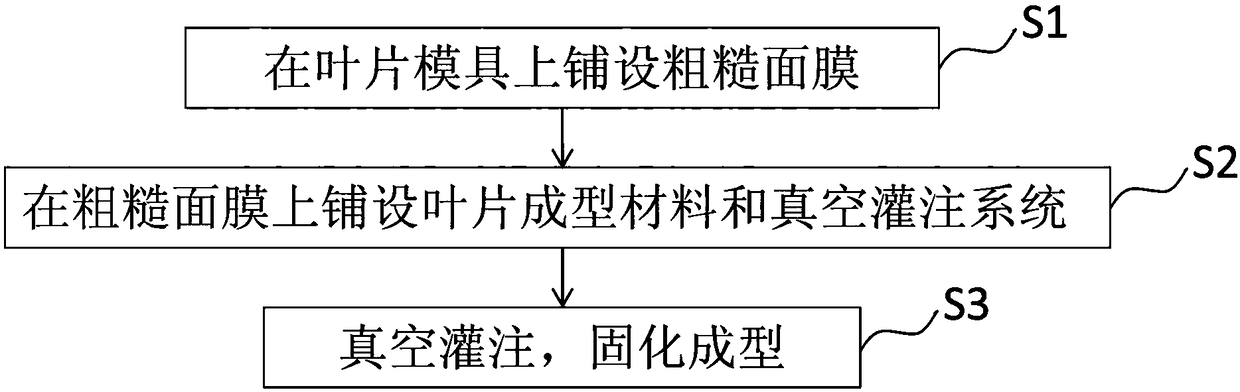

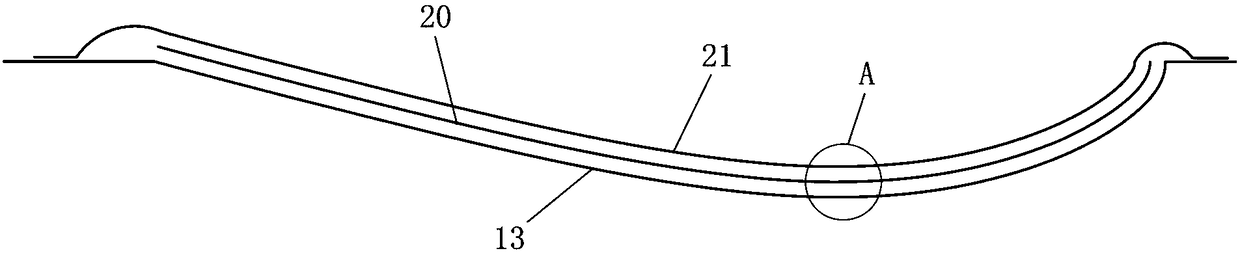

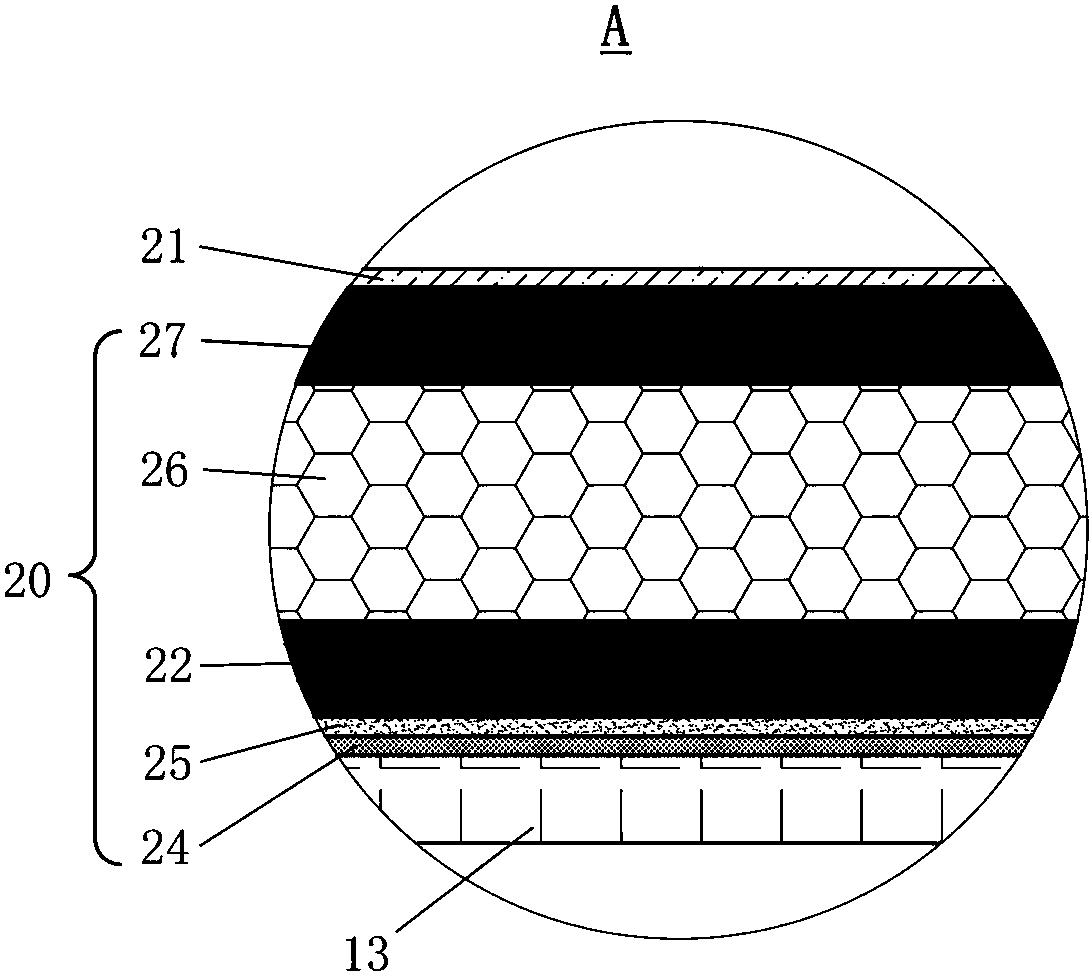

[0023] The following will combine Figure 1 to Figure 3 A method for manufacturing a blade of a wind power generating set according to an exemplary embodiment of the present invention is described in detail. However, the scope of application of the present invention is not limited to blades of wind power generators, and the present invention can also be applied to the manufacture of blades used in other equipment.

[0024] The molds used to make wind turbine blades are divided into suction surface (SS surface) molds and pressure surface (PS surface) molds to prepare suction surface blade moldings and pressure surface blade moldings of wind turbine blades. Then, the mold on the pressure side is turned over 180° to be bonded with the mold on the suction side, and finally demolded. The manufacturin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com